Preparation method of wheel-sticking-free emulsified asphalt for adhesive layer

A technology of emulsified asphalt and non-stick wheels, used in building components, building insulation materials, buildings, etc., can solve the problems of low viscosity at 60°C, poor elastic recovery of evaporation residues, and low PG grade of evaporation residues, and achieve elastic recovery. Good, improved low temperature performance, high low temperature grade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

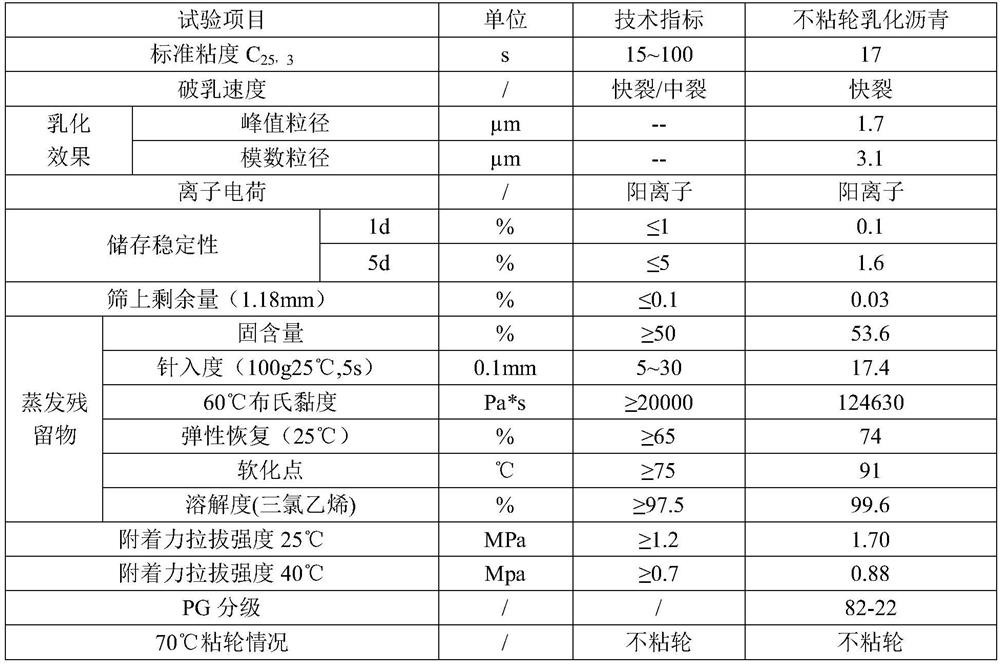

Embodiment 1

[0019] The preparation method of non-stick wheel emulsified asphalt for adhesive layer of the present invention, the steps are as follows:

[0020] (1) Heat 100 parts of Shuanglong 70# asphalt to 175°C, turn on the shearing machine, then add 3.5 parts of SBS and 3 parts of polyethylene wax with a melting point of 99°C to Ssangyong 70# asphalt and shear Cut for 1 hour, add 2 parts of Kelian YT-6 rubber oil after the cutting is completed, and after the temperature rises to 175°C, slowly add 0.3 parts of sulfur, and stir for 5.5 hours after the addition is complete to prepare the parent asphalt.

[0021] (2) Heat the parent asphalt to 165°C, then add 25 parts of sulfonated asphalt powder and 10 parts of rosin resin to the parent asphalt, and stir for 4 hours to prepare the modified asphalt.

[0022] (3) Add 0.45 parts of Aksu 4819 and 0.01 parts of sodium carboxymethylcellulose to 100 parts of water and stir until completely dissolved, then use 0.2 parts of 37% concentrated hydro...

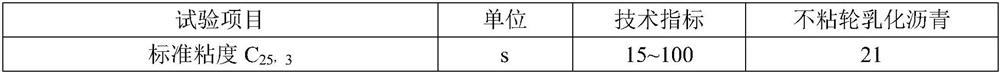

Embodiment 2

[0028] The preparation method of non-stick wheel emulsified asphalt for adhesive layer of the present invention, the steps are as follows:

[0029] (1) Heat 100 parts of SK70# asphalt to 170°C, turn on the shearing machine, and then add 2 parts of SBR and 3 parts of polyethylene wax with a melting point of 115°C to SK70# asphalt for 1 hour After the shearing is completed, add 3 parts of Kelian shell371 rubber oil. After the temperature rises to 170 ° C, slowly add 0.2 parts of sulfur, and stir for 5.5 hours after the addition is complete to prepare the parent asphalt.

[0030] (2) Heat the parent asphalt to 165°C, then add 17 parts of oxidized asphalt powder and 8 parts of terpene resin to the parent asphalt, and stir for 3 hours to prepare the modified asphalt.

[0031] (3) Add 0.4 parts of Aksu 4819 and 0.02 parts of hydroxypropyl methylcellulose to 100 parts of water and stir until completely dissolved, then use 0.1 part of 37% concentrated hydrochloric acid to adjust the p...

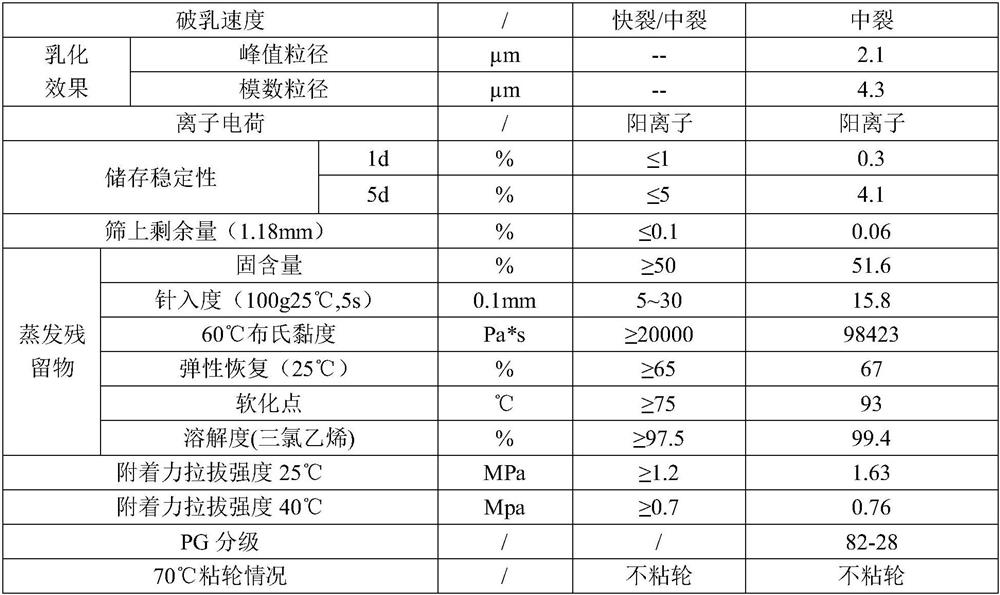

Embodiment 3

[0038] The preparation method of non-stick wheel emulsified asphalt for adhesive layer of the present invention, the steps are as follows:

[0039] (1) Heat 100 parts of Xitai 70# asphalt to 180°C, turn on the shearing machine, and then add 5 parts of hydrogenated SIS and 3 parts of polyethylene wax with a melting point of 123°C to Xitai 70# Cut in the asphalt for 1 hour, add 1 part of Zhongyou KN4008 rubber oil after the cutting is completed, and slowly add 0.15 parts of sulfur after the temperature rises to 180°C, and stir for 6 hours after the addition is complete to prepare the parent asphalt.

[0040] (2) Heat the parent asphalt to 165°C, then add 20 parts of butonite asphalt powder and 5 parts of ancient Marron resin to the parent asphalt, and stir for 3 hours to prepare the modified asphalt.

[0041] (3) Add 1 part of 1831 and 0.015 parts of hydroxypropyl cellulose sodium to 100 parts of water and stir until completely dissolved, then use 0.3 parts of 37% concentrated h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com