Technology for preparing high-separation, low solvent residue and low resolving-out matter PVC/PE/PVCD solid medicinal composite hard sheet

A technology with low solvent residue and high barrier properties, which is applied in lamination auxiliary operations, synthetic resin layered products, lamination, etc., can solve the problem of failure or deterioration of food and medicine, products that cannot meet high requirements, and poor barrier properties of materials. Strong and other problems, to achieve the effect of not easy to be eroded by solvent, easy to operate, and low bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] specific implementation plan

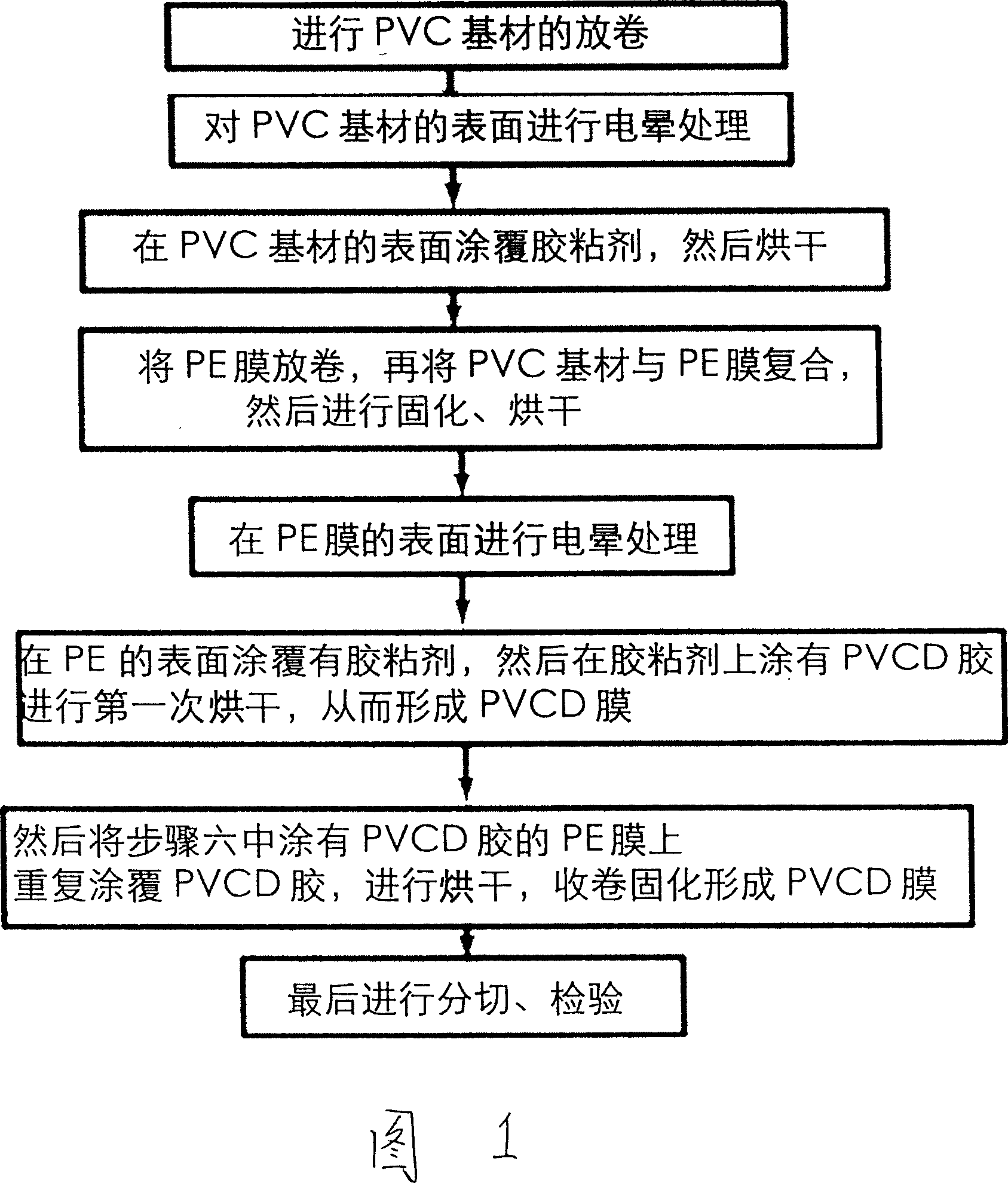

[0009] In Fig. 1, the present invention is a kind of manufacturing process of PVC / PE / PVCD solid pharmaceutical composite hard sheet with high barrier property, low solvent residue, low extractables, it comprises the following steps: Step 1, carry out the release of PVC base material Roll, PVC substrate includes 50Kg of PVC resin powder, 0.7-1Kg of di-n-mercaptan octyl tin, 0.15-0.2Kg of internal slip agent, 0.2-0.3Kg of external slip agent, 0.06Kg of hard Calcium fatty acid, 0.04Kg zinc stearate, 0.03Kg stearic calcium, 0.6-0.8Kg ACR resin as processing aid, 2-3Kg MBC resin as impact modifier, 1-2Kg vinyl chloride - Vinyl acetate resin and 6g color masterbatch are extruded at a high temperature of 200°C, calendered, and cooled into sheets: Step 2, corona treatment is performed on the surface of the PVC base material with a corona machine; Step 3, coating on the surface of the PVC base material Cover with adhesive, the adhesive is water-so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com