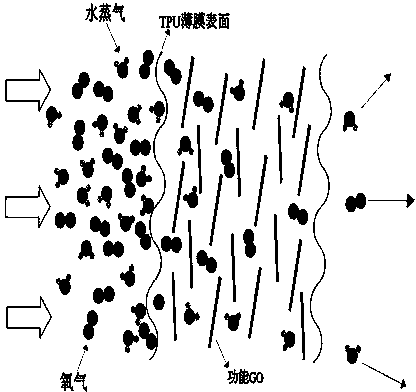

Blocking thermoplastic polyurethane (TPU)/functional graphite oxide composite film and preparation method thereof

A graphene composite and graphene technology, which is applied in the field of polymer composite film preparation, can solve problems such as limiting the application in the barrier field, and achieve the effects of a scientific and reasonable preparation method, strong operability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

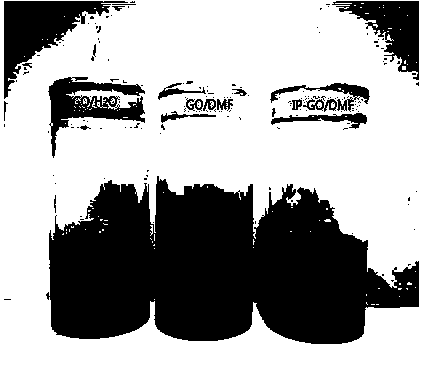

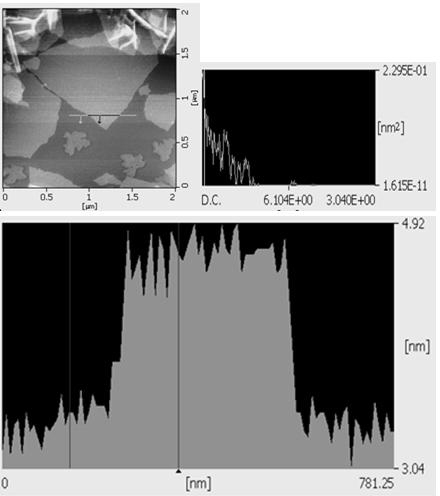

Method used

Image

Examples

Embodiment 1

[0038] Take 10 g of TPU, dissolve it in 40 mL of DMF, and then place it in a blast drying oven at 90 °C to swell for 4 h; weigh 0.1 g of functional graphene oxide and pour it into a 100 mL beaker, then add 10 mL of DMF, at 100 Ultrasonic dispersion was performed in a W ultrasonic cleaner for 10 min, and then the dispersed functional graphene oxide solution was mixed with the swollen TPU solution evenly, and then ultrasonically dispersed in a 100 W ultrasonic cleaner for 1 h. Then mechanically stir in a mechanical mixer for 1 h, then pour the mixed pasty liquid into a small volumetric flask with a straw, and then pump out the air in the pasty liquid on a suction filter until there are no air bubbles in the volumetric flask. Place the glass plate on the film coating machine, and then use the film coating machine to coat a certain thickness of film on the glass plate, then place the glass plate in a vacuum drying oven at 60 °C, and then vacuumize it. After 30 min, open the vent v...

Embodiment 2

[0040] Take 20 g of TPU, dissolve it in 60 mL of DMF, and then place it in an air-dried oven at 80 °C to swell for 6 h; weigh 0.3 g of functional graphene oxide and pour it into a 100 mL beaker, then add 15 mL of DMF, Ultrasonic dispersion was performed in a 100 W ultrasonic cleaner for 20 min, and then the dispersed functional graphene oxide solution was mixed with the swollen TPU solution evenly, and then ultrasonically dispersed in a 100 W ultrasonic cleaner for 3 h. Then mechanically stir in a mechanical mixer for 1 h, then pour the mixed pasty liquid into a small volumetric flask with a straw, and then pump out the air in the pasty liquid on a suction filter until there are no air bubbles in the volumetric flask. Place the glass plate on the film coating machine, and then use the film coating machine to coat a film of a certain thickness on the glass plate, then place the glass plate in a vacuum drying oven at 70 °C, and then vacuumize it. After 20 min, open the vent valv...

Embodiment 3

[0042] Take 15 g of TPU, dissolve it in 50 mL of DMF, and then place it in a blast drying oven at 70 °C to swell for 8 h; weigh 0.5 g of functional graphene oxide and pour it into a 100 mL beaker, then add 30 mL of DMF, Ultrasonic dispersion was performed in a 100 W ultrasonic cleaner for 15 min, and then the dispersed functional graphene oxide solution and the swollen TPU solution were mixed evenly, and then ultrasonically dispersed in a 100 W ultrasonic cleaner for 2 h. Then mechanically stir in a mechanical mixer for 1 h, then pour the mixed pasty liquid into a small volumetric flask with a straw, and then pump out the air in the pasty liquid on a suction filter until there are no air bubbles in the volumetric flask. Place the glass plate on the film coating machine, and then use the film coating machine to coat a certain thickness of film on the glass plate, then place the glass plate in a vacuum drying oven at 80 °C, and then vacuumize it. After 10 min, open the vent valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com