Flexible package film for external resistance layer of polymer lithium ion battery

A technology for lithium ion batteries and flexible packaging films, applied in battery pack parts, circuits, electrical components, etc., can solve the problem of poor bonding compatibility between thermoplastics and metal aluminum foils, increased heat-sealing failure rate of flexible packaging composite materials, and box making. Problems such as the increase in the scrap rate of deep drawing, etc., achieve the effects of excellent plastic interaction elongation and composite firmness, excellent stability, and large initial adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

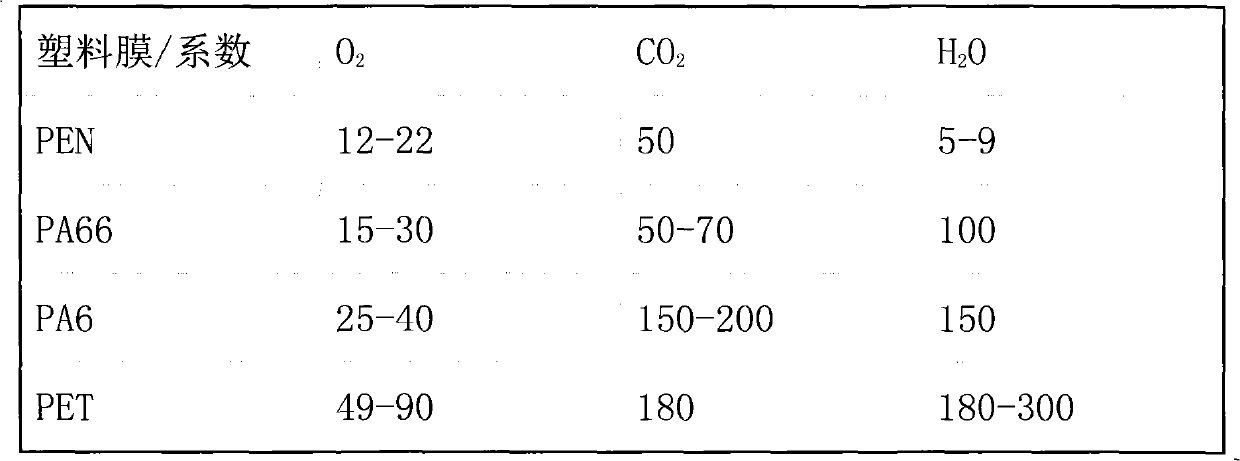

[0018]In the following embodiments, the flexible packaging film for the outer resistance layer of the polymer lithium ion battery includes at least one layer of heat-resistant resin film, which can be selected from: polyethylene terephthalate (PET), nylon Any one of (BOPA) and polyethylene naphthalate (PEN) is used as the external resistance layer of the polymer lithium-ion battery. It is also preferable to choose PEN / PET copolyester film. PEN / PET copolyester film contains 0.1% (mass fraction) ~ 0.4% (mass fraction) SiO 2 Microparticles, and carry out transesterification reaction synthesis intermediate 2,6-ethylene naphthalate (BHEN) by dimethyl naphthalene dicarboxylate (NDC) and ethylene glycol (EG), and BHEN content is 8% ( mole fraction). PEN / PET copolyester film uses zinc acetate as a catalyst, hindered phenol 1010 as an antioxidant, and the reaction temperature is 295°C; the amount of catalyst per mole of BHEN is 4×10 -4 mol, the reaction time is 180min; the amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com