Inorganic matter-filled poriferous composite membrane for liquid flow energy-storage cell and use thereof

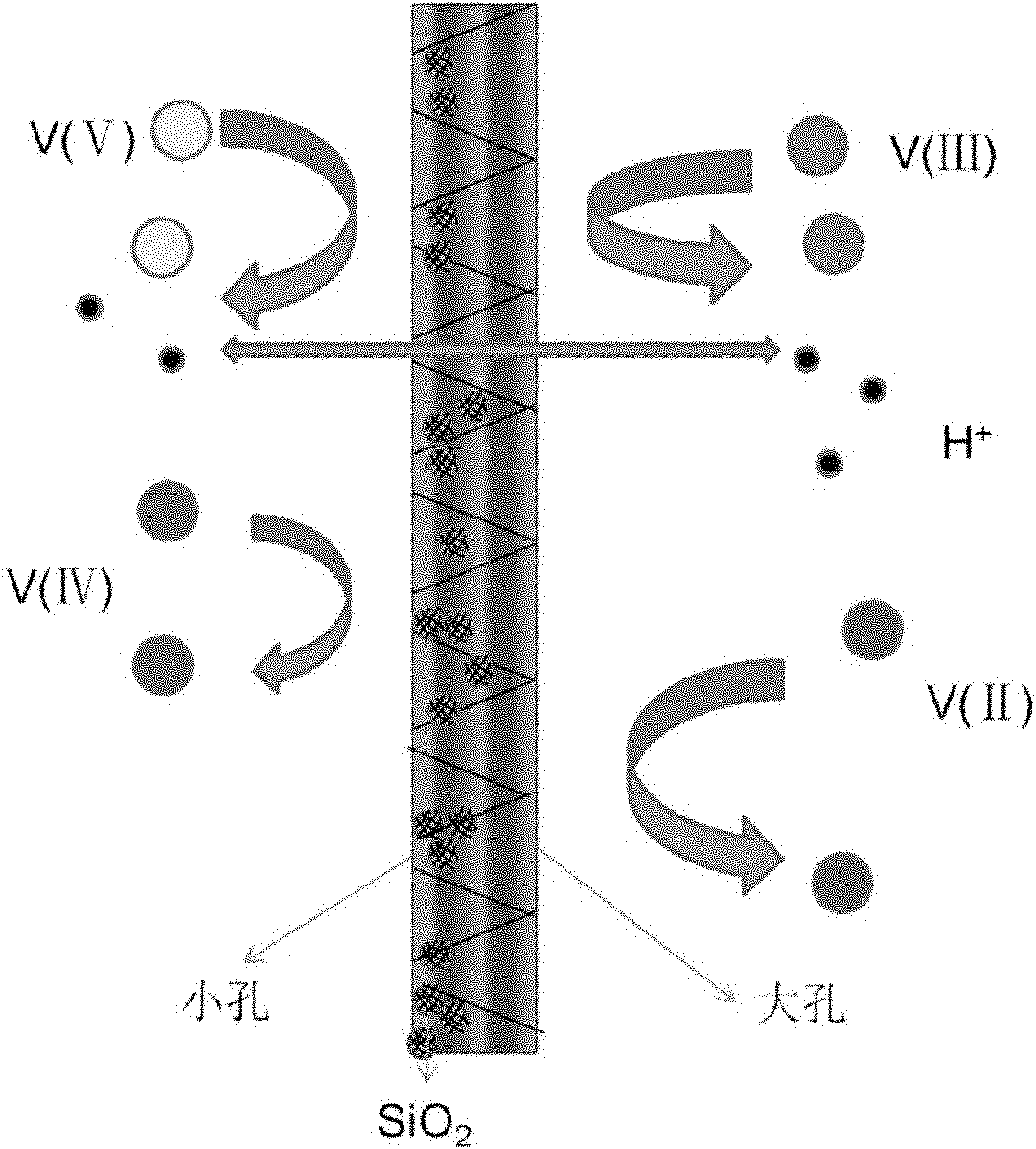

A liquid flow energy storage battery and composite membrane technology, which is applied in the direction of fuel cells, battery pack parts, fuel cell parts, etc., can solve the problems of reducing the pore size and achieve easy mass production, improve conductivity, The effect of improving barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Dissolve 7.5 grams of polyacrylonitrile in 50ml of DMSO, stir for 5 hours, spread the polymer solution on a glass plate, then quickly immerse in 5L of water, solidify, and form a porous diaphragm. Figure 4 A cross-sectional SEM picture of the prepared membrane material is given, showing a regular pore structure.

[0041] Soak the prepared porous membrane in deionized water for 1 hour, take it out, and immerse it in tetraethyl orthosilicate for 2 hours to obtain a silicon dioxide-doped porous composite membrane. Then the porous composite membrane was taken out and dried in vacuum at 60° C. for 6 h. Finally, the porous composite membrane was immersed in 1M sulfuric acid for 24h.

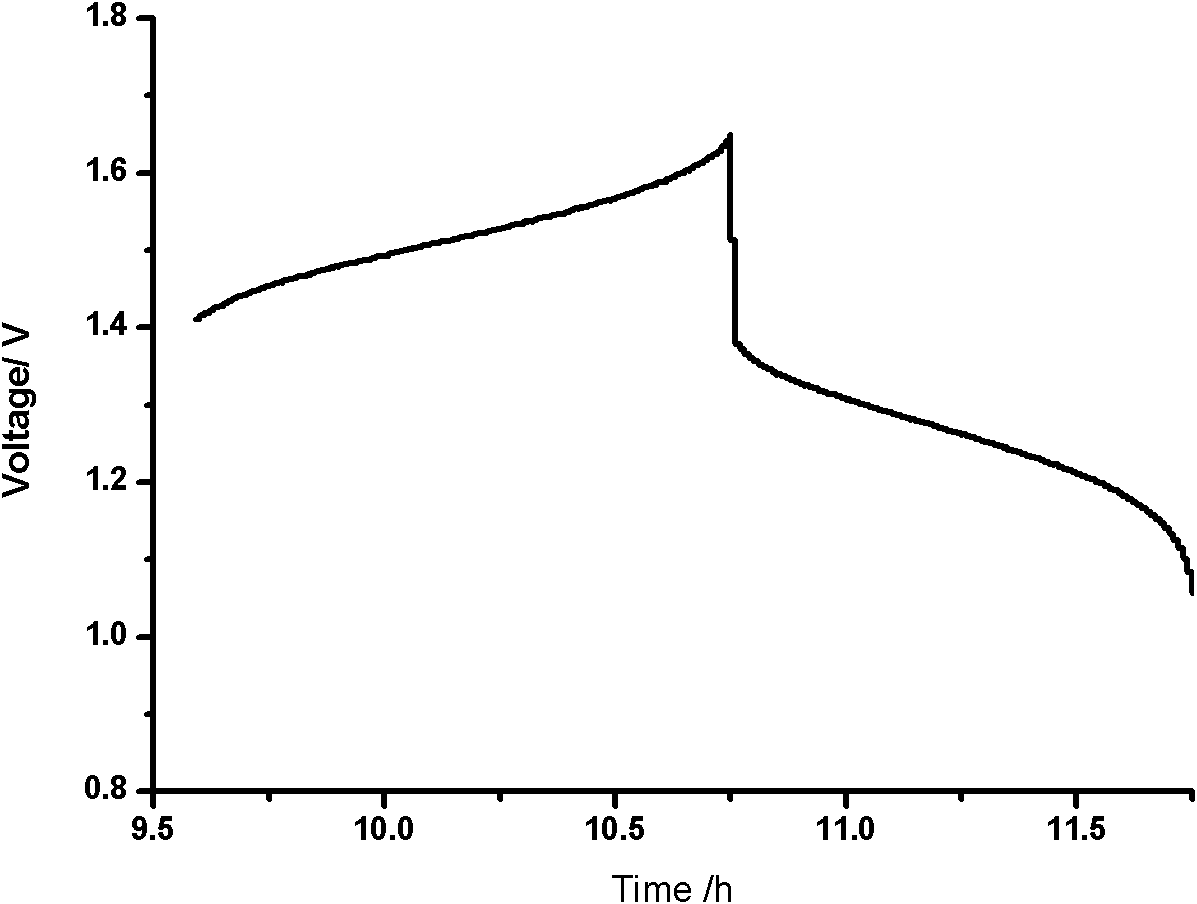

[0042] The all-vanadium flow energy storage battery is assembled by using the prepared porous composite membrane, in which the catalytic layer is activated carbon felt, the bipolar plate is graphite plate, and the effective area of the membrane is 9cm -2, with a current density of 80mA cm ...

Embodiment 2

[0046] 13.5g of polysulfone and 1.5g of sulfonated polyether ether ketone were dissolved in 45g of nitrogen methylpyrrolidone and stirred for 5 hours, and the obtained polymer solution was evenly spread on a glass plate, quickly immersed in 5L of water, and cured for 1 hour to form a porous diaphragm.

[0047] Soak the obtained porous membrane in deionized water for 1 hour, take it out, and then soak it in tetraethyl orthosilicate for 2 hours to obtain a silicon dioxide-doped porous composite membrane. Then the porous composite membrane was taken out and dried in vacuum at 60° C. for 6 h. Finally, the porous composite membrane was soaked in 1M sulfuric acid for 24h.

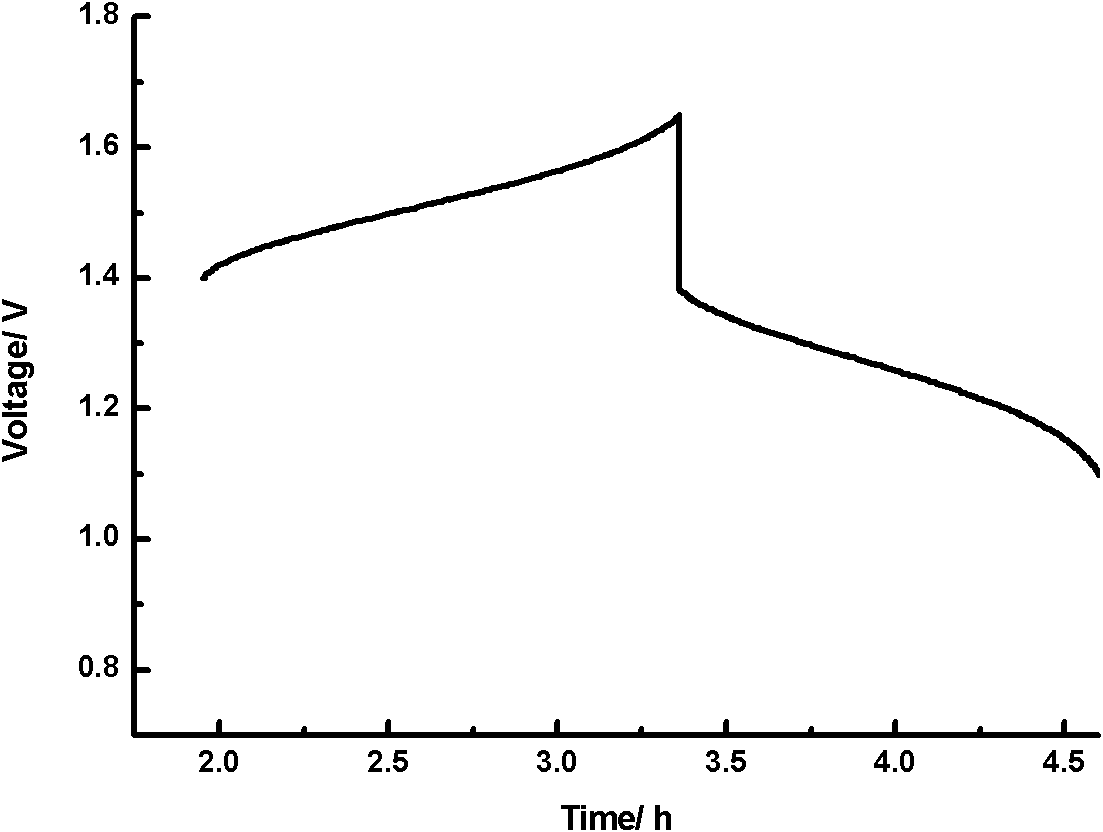

[0048] The all-vanadium flow energy storage battery is assembled by using the prepared silicon dioxide-filled porous composite membrane, the catalytic layer is activated carbon felt, the bipolar plate is graphite plate, and the effective area of the membrane is 9cm -2 , with a current density of 80mA cm -2 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com