Lithium ion secondary battery and preparation method thereof

A secondary battery, lithium ion technology, applied in secondary batteries, electrolyte battery manufacturing, battery electrodes, etc., can solve the problem of low irreversible capacity of lithium batteries, and achieve the effect of improving safety, good safety and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

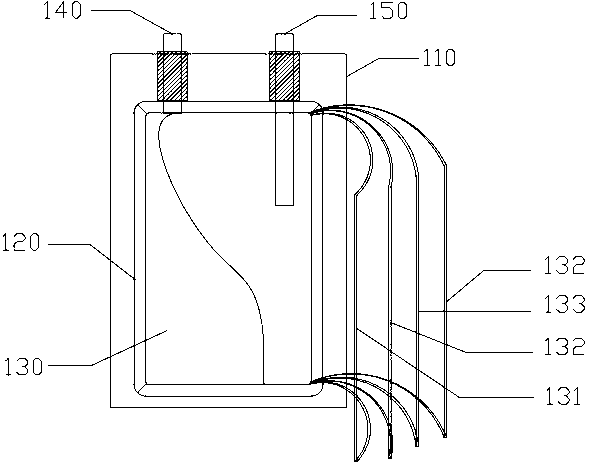

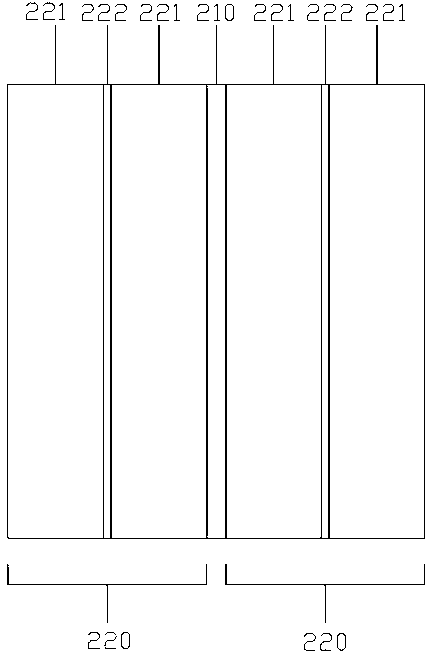

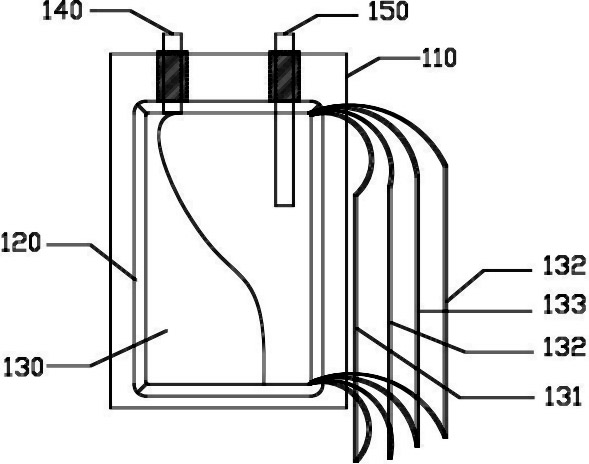

[0073] A lithium-ion secondary battery, comprising a battery case, an aluminum-plastic film packaging bag, a pole core, a positive electrode lug, and a negative pole lug. The pole core is sequentially composed of a negative electrode layer, a separator layer, a positive electrode layer and a separator from the inside to the outside. layer, the negative electrode layer is a layered structure, including a negative electrode current collector, one or both sides of the negative electrode current collector is bonded with a negative electrode material layer composed of a hard carbon material layer and a lithium metal layer, and the negative electrode material The layers are two outer hard carbon material layers and a lithium metal layer between the two hard carbon material layers.

Embodiment 2

[0075] On the basis of embodiment 1, preferably:

[0076] The electric capacity of the lithium metal layer is equal to the total electric irreversible capacity of the two hard carbon material layers.

[0077] The hard carbon material layer is formed by mixing hard carbon material, conductive agent, binder and solvent.

[0078] The hard carbon material is starch-based pyrolytic carbon made by conventional techniques.

[0079] The separator layer is PP / PE / PP.

Embodiment 3

[0081] The preparation method of lithium ion secondary battery of the present invention:

[0082] A. Preparation of positive electrode slurry

[0083] Uniformly mixing the positive electrode material, conductive agent, binder and solvent to obtain positive electrode slurry;

[0084] B. Preparation of positive electrode layer

[0085] The positive electrode slurry prepared in step A is evenly coated on one or both sides of the positive electrode current collector to form a positive electrode material layer with a coating thickness of 100 microns, and the positive electrode material layer and the positive electrode current collector form a positive electrode layer;

[0086] C. Preparation of negative electrode slurry

[0087] Uniformly mixing hard carbon material, conductive agent, binder and solvent to obtain negative electrode slurry;

[0088] D. Coating negative electrode slurry

[0089] Uniformly coating the negative electrode slurry prepared in step C on one or both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com