High-barrier full-biodegrade mulching film and preparation method thereof

A biodegradable mulch film, all-biological technology, applied in the field of biodegradable mulch film, can solve the problems of poor barrier property and low tear strength of fully biodegradable mulch film, and achieve the effects of increased burden, good barrier property, and easy opening of mucous membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

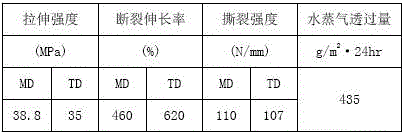

Embodiment 1

[0062] In this embodiment, a high-barrier fully biodegradable mulch film consists of the following components by weight:

[0063] PHBH 20 parts

[0064] 65 copies of PBAT

[0065] PPC 15 copies

[0066] 3 TECs

[0067] Talcum powder 6 parts

[0068] UV 531 1 part

[0069] ADR-4380 0.8 parts

[0070] Polyethylene wax 0.3 parts

[0071] Antioxidant 1010 1 part

[0072] EBS 0.2 copies

[0073] 0.042 parts of coupling agent.

[0074] Wherein, the number-average molecular weight of the PHBH is 600,000, and the ratio of 3-hydroxybutyric acid to 3-hydroxyhexanoic acid in PHBH is 89 / 9; the viscosity-average molecular weight of the PPC is 110,000; the viscosity-average molecular weight of the PBAT is The molecular weight is 80,000; the particle size of talcum powder is ≥2000 mesh.

[0075] The thickness of the high-barrier fully biodegradable mulch film in this example is 10 μm.

[0076] A method for preparing a high-barrier fully biodegradable mulch film of this embodiment ...

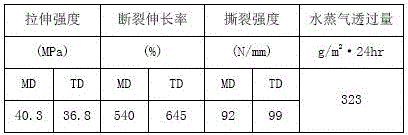

Embodiment 2

[0088] In this embodiment, a high-barrier fully biodegradable mulch film consists of the following components by weight:

[0089] PHBH 30 parts

[0090] 45 copies of PBAT

[0091] PPC 25 copies

[0093] ATBC 3 copies

[0094] UV 531 0.8 parts

[0095] ADR-4300 0.5 parts

[0096] 1 part oleic acid amide

[0097] Antioxidant 1076 0.1 parts

[0098] Antioxidant 168 0.1 parts

[0099] 0.5 parts of ethylene bis stearic acid amide,

[0100] 0.02 parts of coupling agent.

[0101] Wherein, the number-average molecular weight of the PHBH is 760,000, and the ratio of 3-hydroxybutyric acid and 3-hydroxyhexanoic acid is 89 / 11; the viscosity-average molecular weight of the PPC is 90,000; the viscosity-average molecular weight of the PBAT is 55,000; talcum powder particle size ≥ 2000 mesh.

[0102] The thickness of the high-barrier fully biodegradable mulch film in this example is 12 μm.

[0103] A method for preparing a high-barrier fully biodegrada...

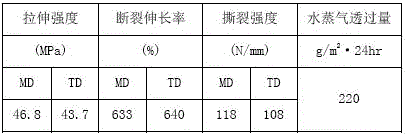

Embodiment 3

[0114] In this embodiment, a high-barrier fully biodegradable mulch film consists of the following components by weight:

[0115] PHBH 25 parts

[0116] 50 copies of PBAT

[0117] PPC 25 copies

[0118] ATBC 4 copies

[0119] Talcum powder 8 parts

[0120] UV 531 1.2 parts

[0121] ADR-4370 0.3 parts

[0122] Oleic acid amide 0.5 parts

[0123] Antioxidant 1010 0.2 parts

[0124] Antioxidant 126 0.2 parts

[0125] Polyethylene wax 0.3 parts

[0126] Zinc stearate 0.3 parts

[0127] 0.08 parts of coupling agent.

[0128] Wherein, the number-average molecular weight of the PHBH is 900,000, and the ratio of 3-hydroxybutyric acid and 3-hydroxyhexanoic acid is 94 / 6; the viscosity-average molecular weight of the PPC is 140,000; the viscosity-average molecular weight of the PBAT is 120,000; the particle size of talcum powder is ≥2000 mesh.

[0129] The thickness of the high-barrier fully biodegradable mulch film in this embodiment is 12 μm.

[0130] A method for preparing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com