Aminated graphene oxide/high-density polyethylane nano composite membrane and preparation method thereof

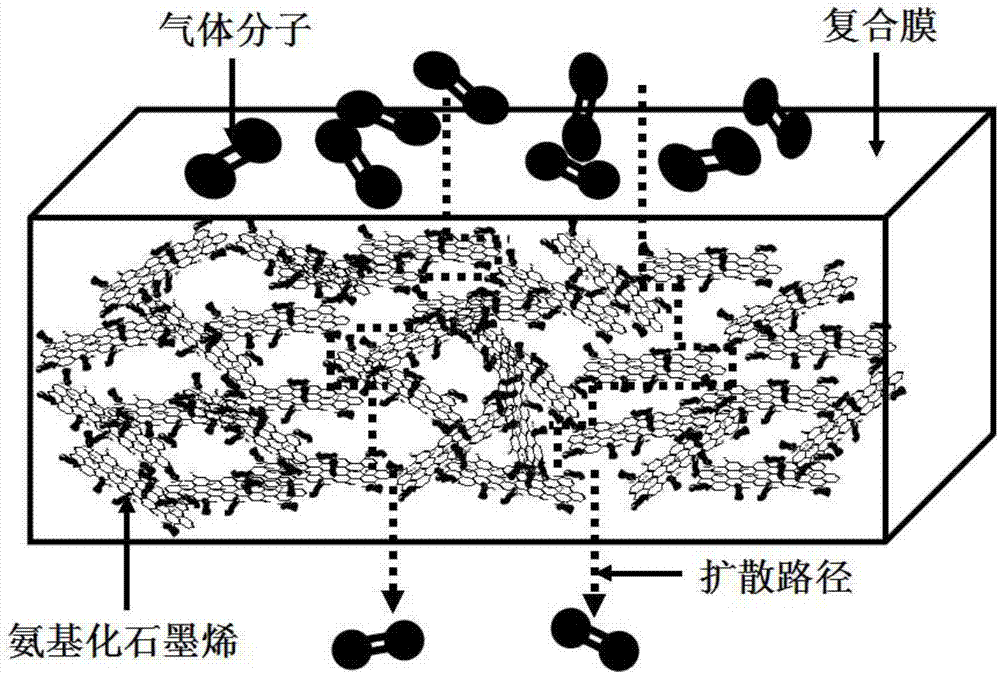

A high-density polyethylene and nano-composite technology, applied in the direction of graphite, can solve the problems of reducing gas permeation channels, unable to improve the barrier properties of non-polar polymers, and high barrier properties, achieving simple process, reducing permeable area, improving The effect of barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of aminated graphene oxide / high-density polyethylene nanocomposite membrane and preparation method thereof, comprises the following steps:

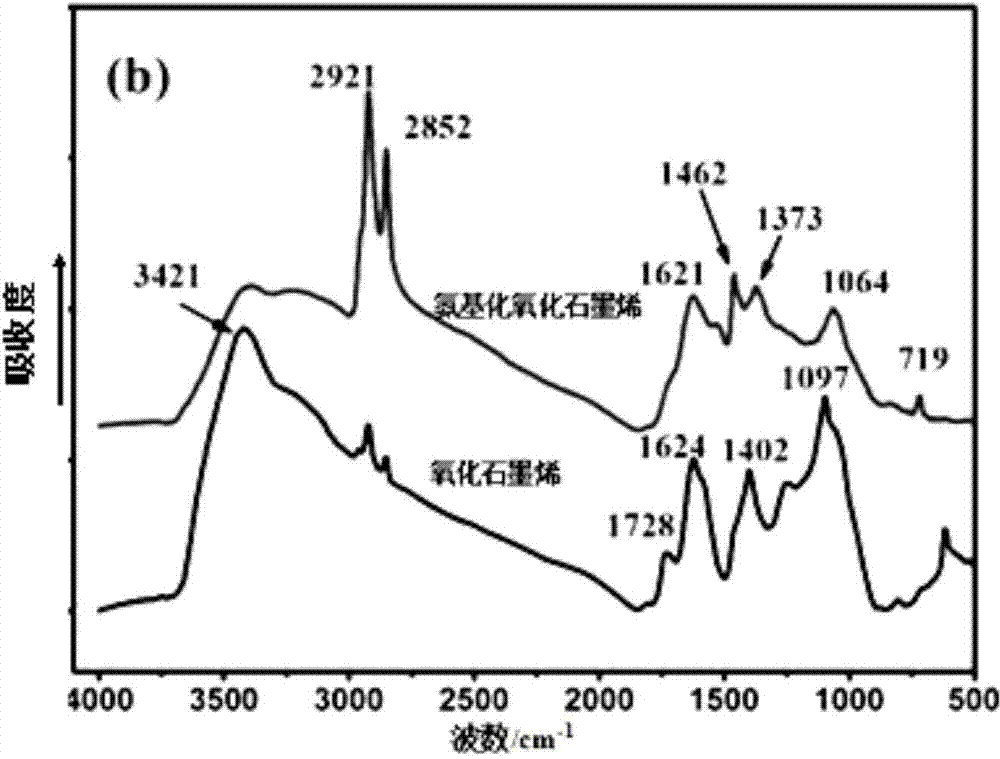

[0039] 1) Preparation of graphene oxide

[0040] First, graphene oxide was prepared by the improved Hummers method: 2 g of expandable graphite was weighed and added to 100 mL of concentrated H with a mass concentration of 98%. 2 SO 4 After stirring in an ice-water bath, gradually add 10g KMnO 4 , at 10°C, reacted for 2.5h. Then continue to react in a constant temperature water bath at 35°C for 1.25h, then add 400mL of deionized water and 5mL of 30% H 2 o 2 After stirring evenly, the mixture was filtered while it was hot, washed with 30 mL of 5% HCl solution, and then repeatedly washed with a large amount of deionized water until there was no SO in the filtrate. 4 2- (with BaCl 2 solution test), and then use ultrasonic action to disperse it in 200mL deionized water to obtain graphene oxide colloidal suspension.

[004...

Embodiment 2

[0049] A kind of aminated graphene oxide / high-density polyethylene nanocomposite membrane and preparation method thereof, comprises the following steps:

[0050] 1) Preparation of graphene oxide

[0051] First, graphene oxide was prepared by the improved Hummers method: 3g of expandable graphite was weighed and added to 110mL of concentrated H with a mass concentration of 98%. 2 SO 4 After stirring in an ice-water bath, gradually add 12g KMnO 4 , At 15°C, react for 2h. Then continue to react in a constant temperature water bath at 33°C for 1.5h, and then add 450mL of deionized water and 20mL of H2O with a mass concentration of 30% to the mixture system 2 o 2 After stirring evenly, the mixture was filtered while it was hot, washed with 35 mL of 5% HCl solution, and then repeatedly washed with a large amount of deionized water until there was no SO in the filtrate. 4 2- (with BaCl 2 solution test), and then use ultrasonic action to disperse it in 300mL deionized water to ...

Embodiment 3

[0058] A kind of aminated graphene oxide / high-density polyethylene nanocomposite membrane and preparation method thereof, comprises the following steps:

[0059] 1) Preparation of graphene oxide

[0060] First, graphene oxide was prepared by the improved Hummers method: 4g of expandable graphite was weighed and added to 120mL of concentrated H with a mass concentration of 98%. 2 SO 4 After stirring in an ice-water bath, gradually add 20g KMnO 4 , At 15°C, react for 2h. Subsequently, the reaction was continued for 1 h in a constant temperature water bath at 37°C, and 600 mL of deionized water and 25 mL of H2O with a mass concentration of 30% were successively added to the mixture system. 2 o 2 After stirring evenly, the mixture was filtered while it was hot, washed with 40 mL of 5% HCl solution, and then repeatedly washed with a large amount of deionized water until there was no SO in the filtrate. 4 2- (with BaCl2 solution test), and then use ultrasonic action to dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com