Transparent flame-retarding polyester film and preparation method thereof

A flame retardant polyester and film technology, applied in the field of transparent flame retardant polyester film and its production, can solve the problems of melt droplets, not reaching the VTM-0 flame retardant level, and not mentioning the yellowing of the film, and achieve high resistance flammability, reduction of film yellowing, high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

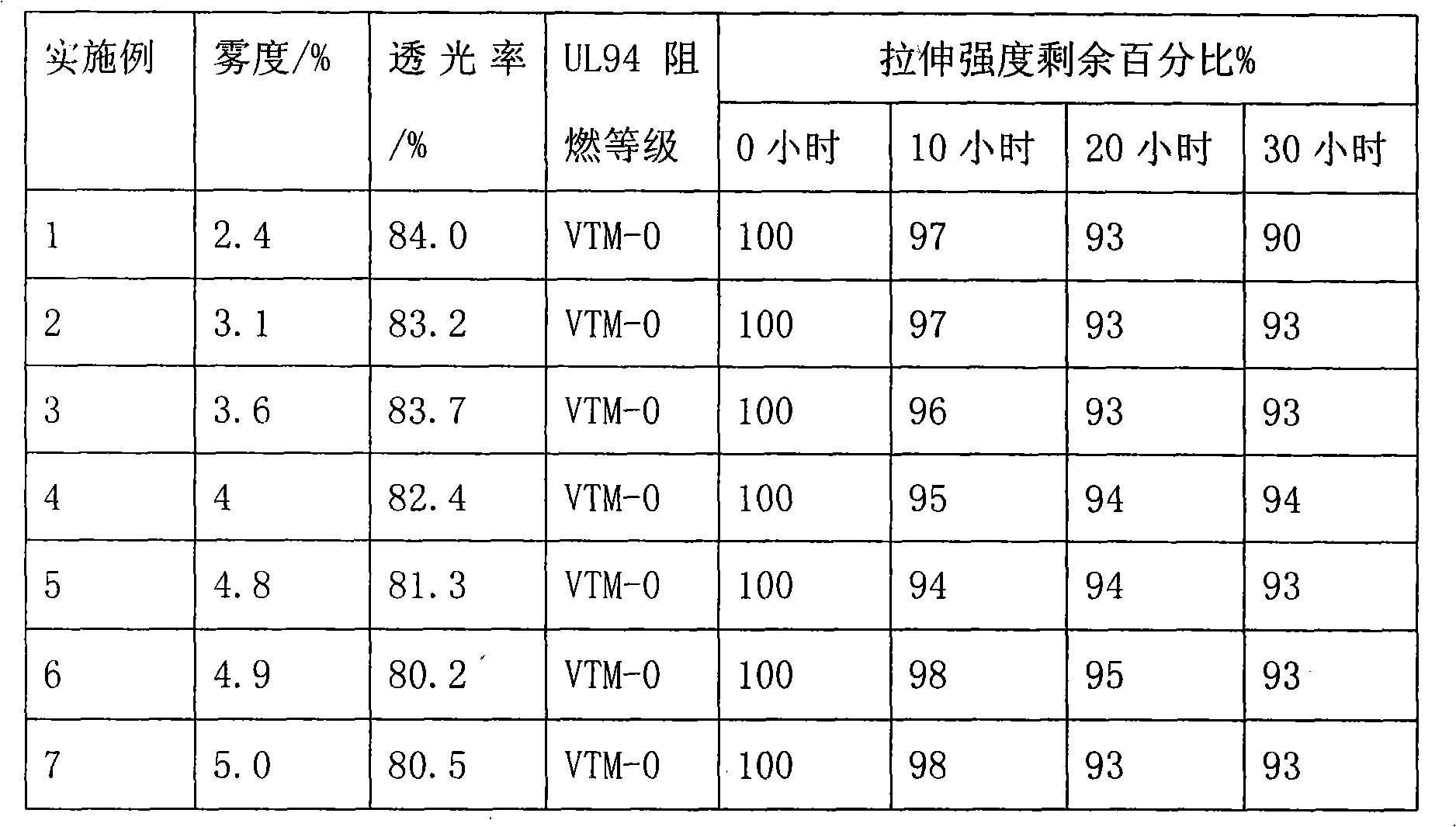

Examples

Embodiment 1

[0018] The preparation method of transparent flame-retardant polyester film of the present invention, by weight ratio,

[0019] (1) Fully mix 100 parts of terephthalic acid and 35 parts of ethylene glycol, then add a mixture of 7.3 parts of structural phosphorus flame retardant and 30 parts of ethylene glycol and 3 parts of trioxide The catalyst of diantimony and 1.5 parts of triphenyl phosphite stabilizer are fully stirred, the reaction temperature is controlled at 100°C, the vacuum degree is controlled at 400pa, and the esterification reaction is carried out after stirring for 1 hour, wherein the phosphorus-based flame retardant is [ 6-oxo(6H-dibenzo-(c,e)(1,2)-oxaphosphorin-6-one)methyl]-butanedioic acid (DDP) or [6-oxo(6H-di Benzo-(c,e)(1,2)-oxaphosphorin-6-one)methyl]-succinic acid derivatives (DDP derivatives), after the esterification reaction, excess ethylene glycol is recovered . The polycondensation reaction was carried out at a reaction temperature of 260° C. and ...

Embodiment 2

[0023] The preparation method of transparent flame-retardant polyester film of the present invention, by weight ratio,

[0024] (1) Fully mix 100 parts of terephthalic acid and 35 parts of ethylene glycol, then add a mixture of 7.3 parts of structural phosphorus flame retardant and 30 parts of ethylene glycol and 4 parts of ethylene glycol The antimony alcohol catalyst and 3 parts of triphenyl phosphate stabilizer are fully stirred, the reaction temperature is controlled at 115°C, the vacuum degree is controlled at 600pa, and the esterification reaction is carried out after stirring for 0.75h, wherein the phosphorus-based flame retardant is 2 -Carboxyethylphenylphosphinic acid (CEPPA) or phenyldicarboxyphenylphosphine oxide (BCPPO), after the esterification reaction, excess ethylene glycol is recovered. The polycondensation reaction was carried out at a reaction temperature of 290° C. and a vacuum of 10 Pa for 3 hours to obtain copolymerized flame-retardant polyester chips.

...

Embodiment 3

[0028] The preparation method of transparent flame-retardant polyester film of the present invention, by weight ratio,

[0029] (1) Fully mix 100 parts of terephthalic acid and 35 parts of ethylene glycol, then add a mixture of 10.5 parts of structural phosphorus flame retardant and 30 parts of ethylene glycol and 3.5 parts of trioxide The catalyst of diantimony and 2 parts of trimethyl phosphate stabilizer are fully stirred, the reaction temperature is controlled at 110°C, the vacuum degree is controlled at 500pa, and the esterification reaction is carried out after stirring for 1 hour, wherein the phosphorus-based flame retardant is [6 -Oxy(6H-dibenzo-(c,e)(1,2)-oxaphosphorin-6-one)methyl]-butanedioic acid (DDP) and [6-Oxy(6H-diphenyl And-(c,e)(1,2)-oxaphosphorin-6-one)methyl]-succinic acid derivatives (DDP derivatives) mixtures, in which [6-oxo(6H-diphenyl And-(c,e)(1,2)-oxaphosphorin-6-one)methyl]-butanedioic acid (DDP) is 4.38 parts, 6-oxo(6H-dibenzo-(c, e) 2.92 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com