Degradable biaxially-oriented polylactic acid cigarette film and preparation method thereof

A technology of biaxial stretching and polylactic acid, applied in chemical instruments and methods, sustainable manufacturing/processing, flat products, etc., can solve problems such as environmental pollution and difficult application of optical properties, and achieve the effect of overcoming non-degradable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

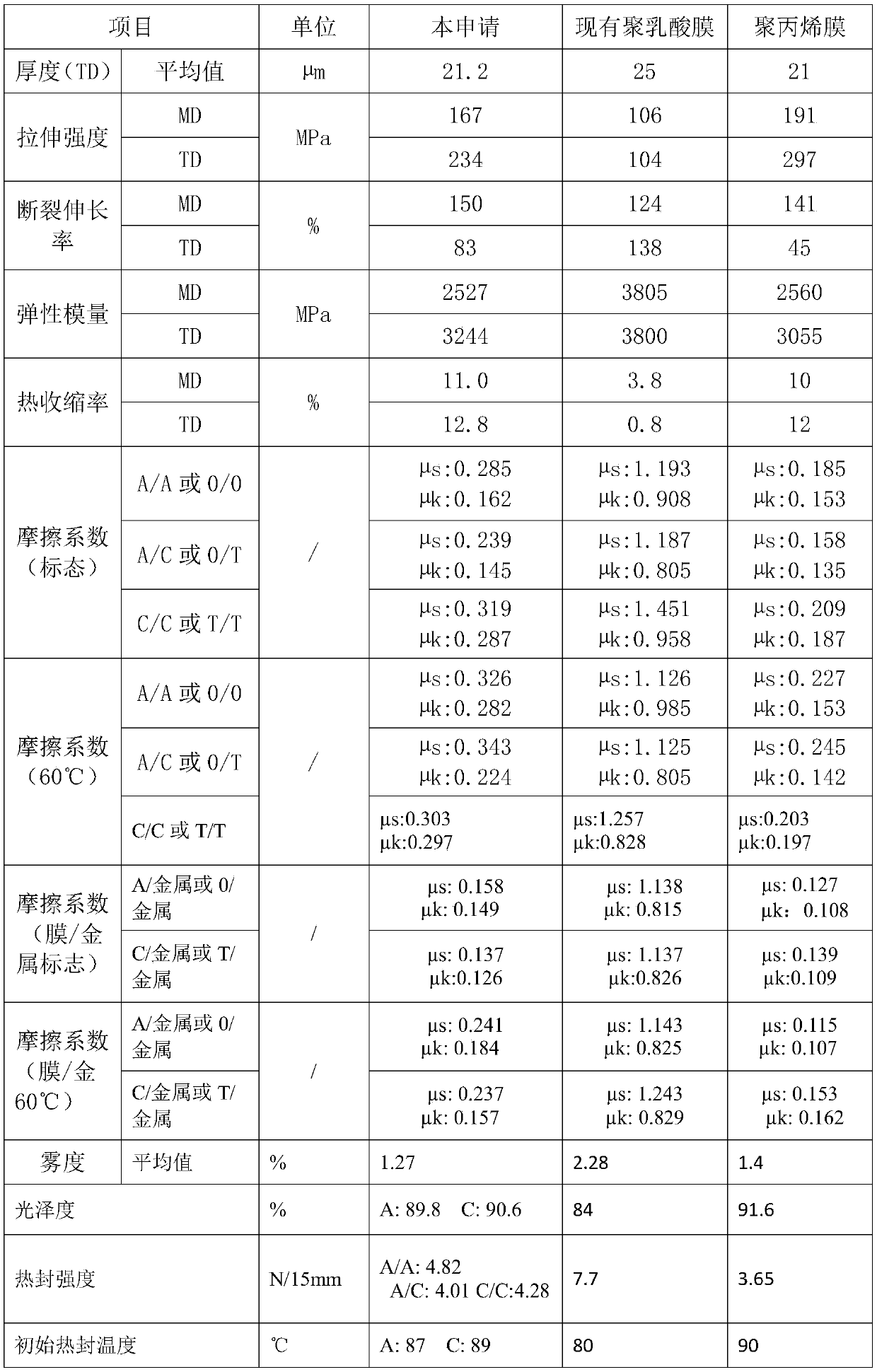

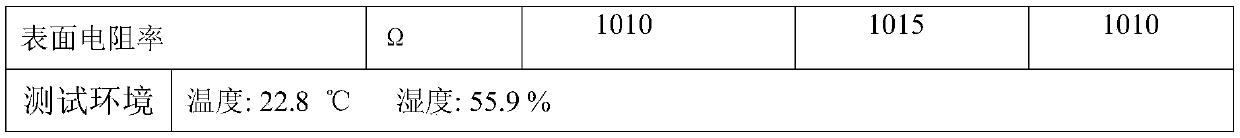

[0025] A degradable biaxially stretched polylactic acid cigarette film, consisting of three layers of co-extruded outer layer A, core layer B and inner surface layer C, the layers A, B and C respectively include heat-sealable PLA or crystalline Type PLA, by mass percentage,

[0026] The A layer includes 80-90% heat-sealing type I PLA, 8-15% slip agent and 2-5% anti-blocking agent, and the heat-sealing type I PLA is composed of 70-80% crystalline PLA and 20-30% amorphous PLA composition;

[0027] The B layer includes 90-95% crystalline PLA, 1-5% antistatic agent, 1-2% stiffening agent, and 1-5% toughening agent;

[0028] The C layer includes 94-97% heat-sealing type II PLA, 2-3% slip agent and 1-3% anti-blocking agent, and the heat-sealing type II PLA consists of 75-85% crystalline PLA and 15-25% % composition of amorphous PLA.

[0029] The slip agent is one or more of oleic acid amide, erucamide and silicone; the anti-blocking agent is one of silicon dioxide, titanium dioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com