Method for manufacturing porous multilayer composite diaphragm for lithium battery and diaphragm

A multi-layer composite, lithium battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of low film breaking temperature, unsafe, small difference between film breaking temperature and closed cell temperature, etc.

Inactive Publication Date: 2011-05-18

FOSHAN JINHUI HIGH TECH OPTOELECTRONICS MATERIAL

View PDF2 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The closed cell temperature of the polyolefin separator is more suitable, however, its rupture temperature is low, and the difference between the rupture temperature and the closed cell temperature is small, and there are potential safety hazards when it is used as a lithium ion battery separator

For example, the closed cell temperature of the PE diaphragm is 130-140°C, which is more suitable, but the heat resistance of the PE diaphragm is poor, and the membrane rupture temperature is not higher than 150°C, that is, the maximum difference between the closed cell temperature and the rupture temperature does not exceed 20°C, which is quite unsafe

[0008] The rupture temperature of the heat-resistant resin diaphragm is relatively high, but its closed cell temperature is relatively high, which also fails to meet the safety requirements

For example, the pp diaphragm has a high membrane rupture temperature, greater than 170°C; however, its closed cell temperature is also very high, above 150°C, which also fails to meet the safety requirements.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

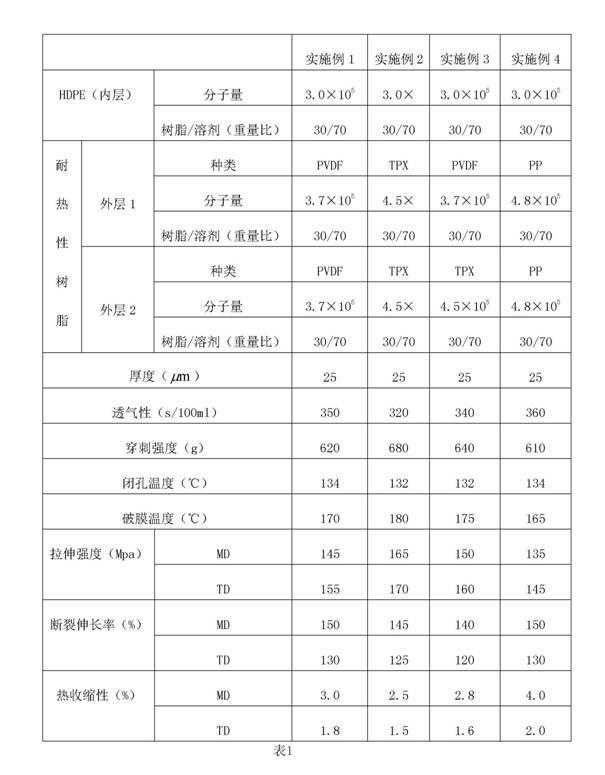

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| membrane rupture temperature | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a method for manufacturing a porous multilayer composite diaphragm for a lithium battery and a diaphragm manufactured by the same. In the method, polyethylene mixed with solvent and heat-resistant resin mixed with the solvent are extruded by using a multilayer die head of a double-screw extruder, and the extruded products are subjected to chill casting, two-way stretch, washing, drying and heat setting to manufacture the porous multilayer composite diaphragm. An integral structure of the manufactured diaphragm comprises a polyethylene layer and a heat-resistant resin layer, has low closed-cell temperature given by the polyethylene and high diaphragm breaking temperature given by the heat-resistant resin layer simultaneously. Simultaneously, the addition of the heat-resistant resin layer reduces the heat contractibility of the multilayer diaphragm and improves the puncture strength of the multilayer diaphragm, so the multilayer diaphragm has more excellent performance.

Description

technical field [0001] The patent of the present invention relates to a preparation method of a porous multilayer composite separator for lithium batteries, and the separator prepared by the method. Background technique [0002] Rechargeable lithium-ion secondary batteries have the advantages of high operating voltage, high specific energy, long cycle life, no memory effect, no pollution, and fast charging and discharging, and have become a hot spot in the research of new power supply technologies. [0003] A common lithium-ion secondary battery consists of a lithium oxide cathode material, a carbon anode material, an electrolyte, a diaphragm, and a battery casing packaging material. Among them, the separator is an important part of the lithium-ion secondary battery. It prevents the contact between the positive and negative active materials in the battery and causes a short circuit. It is a non-electronic conductor, but it allows lithium ions to pass through. The role of io...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M2/16

CPCY02E60/12Y02E60/10

Inventor 邱均峰王松钊吴耀根蔡朝辉

Owner FOSHAN JINHUI HIGH TECH OPTOELECTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com