A kind of high elastic warm fleece knitted fabric and preparation method thereof

A knitted fabric and raised technology, applied in the directions of knitting, weft knitting, fabric surface trimming, etc., can solve the problems of skin contact reaction, easy aging, poor heat resistance, etc., and achieve elegant luster, good wearing performance, The effect of improving the fluffy feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Set the workshop temperature to 25°C and humidity to 75%. Positive weft knitting terry machine is adopted, and the machine number is 20G for weaving.

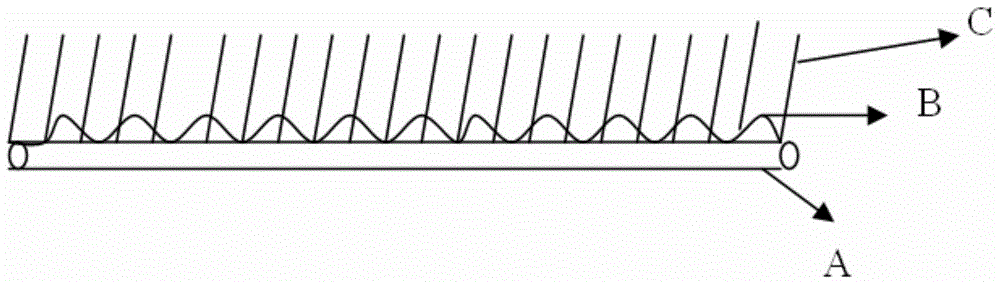

[0045] Select the 300D / 288F polyester filament with the number of network points of 90-10 / m to be fed through the first path of the weft knitting machine, select the 70D / 68F nylon filament to be fed through the second path of the weft knitting machine, and select 40D spandex bare The silk is fed through the third way of the weft knitting machine, and the weaving weight is 240-250g / m 2 rough.

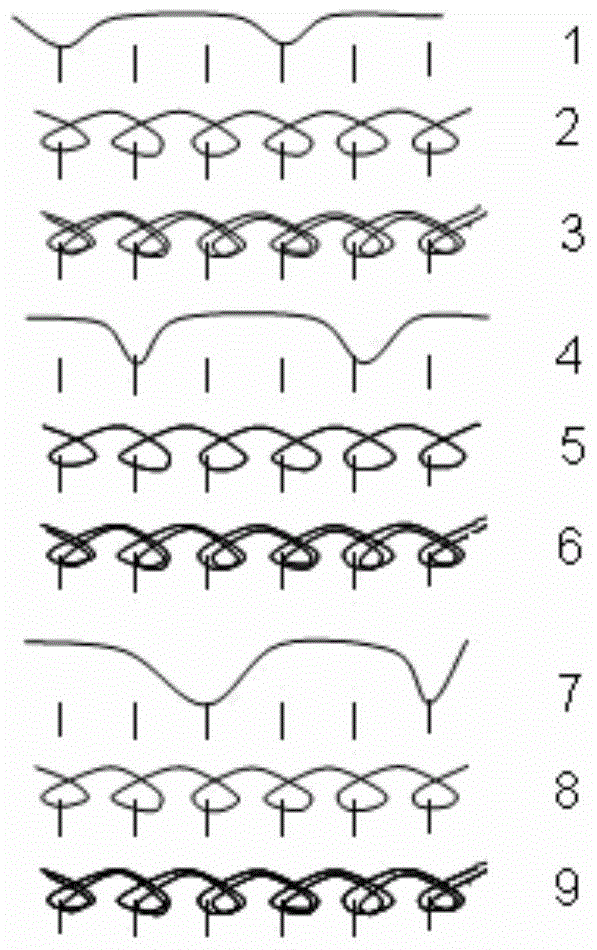

[0046] Among them, the weaving blank process adopts the ABC knitting needle arrangement method, the first road adopts the A tuck, BC floating thread technology; the second road adopts the ABC knitting technology; the third road adopts the ABC plating knitting technology; the fourth road adopts the B Tuck, AC floating thread process; No. 5 adopts ABC loop forming process; No. 6 adopts ABC plating loop forming process; No. 7 adopts...

Embodiment 2

[0051] Set the workshop temperature to 25°C and humidity to 75%. Positive weft knitting terry machine is adopted, and the machine number is 24G for upper knitting.

[0052] Select 150D / 288F polyester filament with a network point number of 120-130 / m to be fed through the first path of the weft knitting machine, select 70D / 68F nylon filament to be fed through the second path of the weft knitting machine, and select 55D spandex bare The silk is fed through the third way of the weft knitting machine, and the weaving weight is 190-200g / m 2 rough.

[0053] Among them, the weaving blank process adopts the ABC knitting needle arrangement method, the first road adopts the A tuck, BC floating thread technology; the second road adopts the ABC knitting technology; the third road adopts the ABC plating knitting technology; the fourth road adopts the B Tuck, AC floating thread process; No. 5 adopts ABC loop forming process; No. 6 adopts ABC plating loop forming process; No. 7 adopts C tu...

Embodiment 3

[0058] Set the workshop temperature to 25°C and humidity to 75%. Adopt active weft knitting terry machine, machine number is 18G upper weaving.

[0059] Select 170D / 288F polyester filament with a network point number of 100-120 / m to be fed through the first path of the weft knitting machine, select 75D / 68F nylon filament to be fed through the second path of the weft knitting machine, and select 50D spandex bare The silk is fed through the third way of the weft knitting machine, and the weaving weight is 190-200g / m 2 rough.

[0060] Among them, the weaving blank process adopts the ABC knitting needle arrangement method, the first road adopts the A tuck, BC floating thread technology; the second road adopts the ABC knitting technology; the third road adopts the ABC plating knitting technology; the fourth road adopts the B Tuck, AC floating thread process; No. 5 adopts ABC loop forming process; No. 6 adopts ABC plating loop forming process; No. 7 adopts C tuck, AB float process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com