Silk cotton knitted fabric and production method thereof

A technology for cotton knitted fabric and production method, which is applied in the direction of fabric surface trimming, plant fiber, biochemical fiber treatment, etc., can solve the problems of expensive equipment, shrinking into bundles, not enough softness, etc., and achieves simple and convenient operation, increased resilience, The effect of no feathers on the canvas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

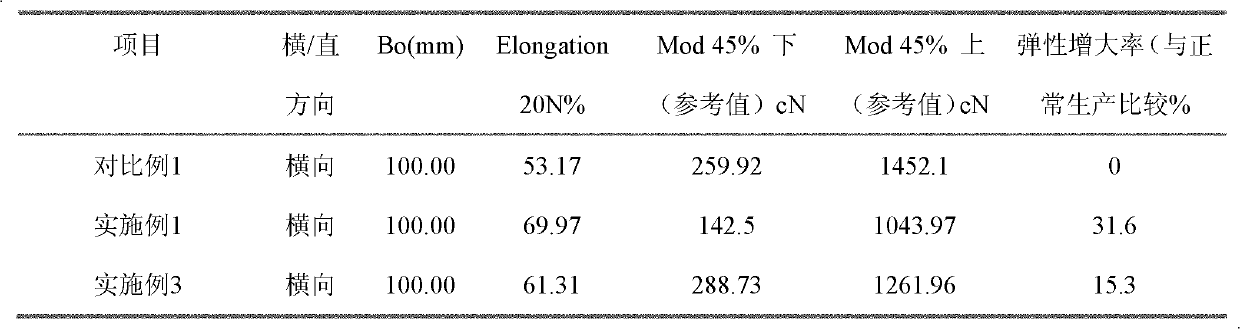

Embodiment 1

[0019] Example 1: 40S / 1 compact cotton double-sided 21.77kg, water ratio: 1:16, color: bleached.

[0020] The raw material cloth is prepared and smelted by the conventional raw cloth, and then put into the Fong’s SYN-50 airflow machine for bright treatment. The machine conditions are: single cloth, pressure difference 90%, fan 27%, machine speed 25m / The water ratio of 2'22" bright treatment is 1:16, add HAc 0.348kg, NaAc 0.174kg, INDIAGE MAXL 0.195kg to the water, pH value is 42, treatment temperature is 55℃, treatment for 50 minutes, after treatment, use Na 2 CO 3 Neutralize the washing water, add white to neutralize the tank after brightening. After normal drying, the cloth is fixed and softened in a hot air sizing machine. The setting conditions are: 150°C×6+130°C+107°C, machine speed: 20m / min; Slurry formula: 20g / l silkasoft ra, 40g / l smartil vst, 0.3g / l malic acid, the solvent is water, the excess rate is 80%, after setting the shrinking machine, the machine speed is 1...

Embodiment 2

[0021] Example 2: 40S / 1 compact cotton double-sided 20.87kg, water ratio: 1:15, color: deep black

[0022] The raw material cloth is prepared and smelted by the conventional raw cloth, and then put into the Fong’s SYN-50 airflow machine for bright treatment. The machine conditions are: single cloth, pressure difference 90%, fan 27%, machine speed 25m / 2'20". The water ratio of bright treatment is 1:15, add HAc 0.313kg, NaAc 0.156kg, INDIAGE MAXL 0.145kg in water, treatment temperature is 55℃, treatment time is 50min, pH value is 4.1, after treatment use Na 2 CO 3 Neutralize and wash water, brighten and dye out of the vat normally, then dry the cloth normally, and then carry out fixed-sizing finishing and soft finishing in the hot-air sizing machine. The setting conditions are: 150°C×6+130°C+107 ℃, machine speed: 20m / min; the softening agent for softening and finishing is made of: 25g / l silkasoft ra, 30g / l smartil vst, 30g / l kepler427 (fixing agent), 0.3g / l malic acid, and th...

Embodiment 3

[0023] Example 3: 40S / 1 compact cotton double-sided 19.96kg, water ratio: 1:18, color: floral yarn washing water

[0024] The floral yarn is pre-determined, the greige cloth is sewed, and it is desoftened until dripping in the vat. After washing, it is brightened. The brightening treatment is produced in the SME water flow vat of Yongyi Xinda. The operating condition is 7psi and the machine speed is 45m / 1 '40". The water ratio of bright treatment is 1:18, HAc 0.359kg, NaAc 0.18kg, INDIAGE MAXL 0.199kg are added to the water, the pH value is 4.3, the treatment temperature is 55°C, and the treatment time is 80min. Na 2 CO 3 Neutralize the washing water, take it out of the vat after bright treatment, dry the cloth normally, and then carry out fixed and soft finishing in the hot air sizing machine after drying. The setting conditions are: 150℃×6+130℃+107℃, machine speed : 25m / min, the softener slurry for softening and finishing: 15g / l silkasoft ra, 35g / l smartil vst, 0.3g / l mali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com