Chemical fiber filament

A filament and chemical fiber technology, applied in the field of chemical fiber filament, to achieve the effects of easy dyeing, improved moisture absorption and air permeability, and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

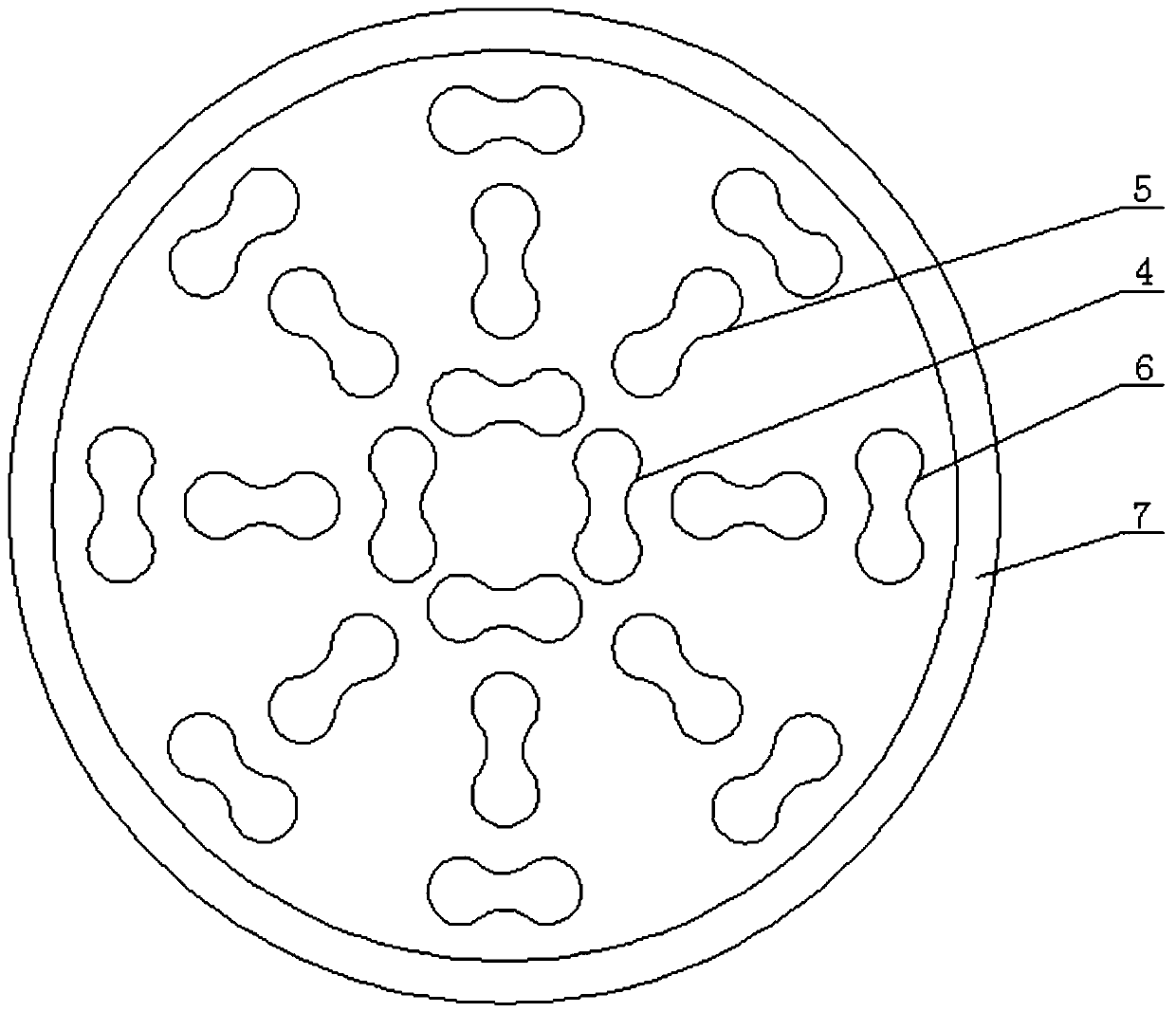

[0010] Such as figure 1 , figure 2 As shown, a chemical fiber filament includes several monofilaments 1 and an annular natural fiber layer 7, the natural fiber layer 7 is a silk layer, and the natural fiber layer 7 can improve the moisture absorption and air permeability of the present invention.

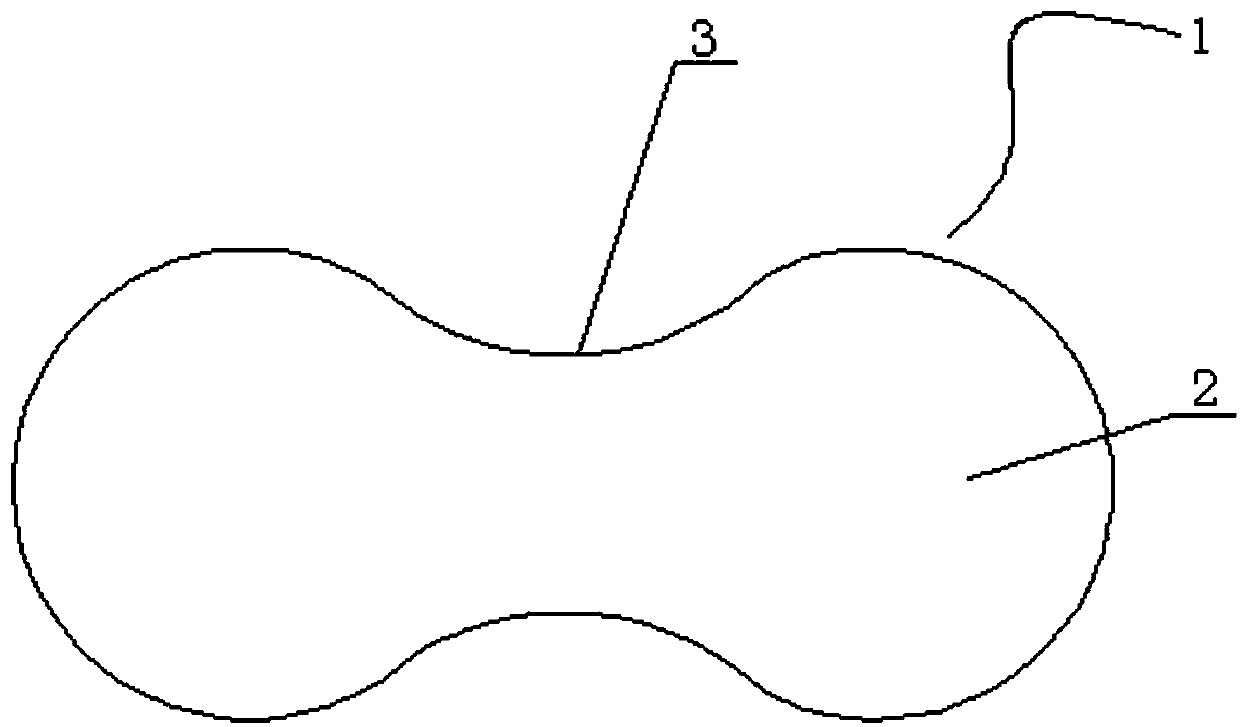

[0011] The cross-section of the monofilament 1 is 8-shaped, two symmetrical circular protrusions 2 are formed at both ends of the monofilament 1, and two symmetrical arc-shaped grooves 3 are formed in the middle of both sides of the monofilament 1. The head 2 is transitionally connected through the groove 3. This setting increases the rigidity of the monofilament 1, has good lodging resistance, good moisture absorption and ventilation, elegant luster, easy dyeing, and softer hand feeling.

[0012] The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com