Saponification Dyeing Method of Nylon Acetate Fiber Composite Yarn

A technology for nylon fibers and yarns, which is applied in the field of saponification dyeing of nylon acetate fiber composite yarns, which can solve the problems of difficulty in dyeing dark colors, low saturation value, and low color fastness, and achieve soft and smooth hand feeling, bright dyeing, and dyeing The effect of strong fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Dyeing raw materials: 26 acetate nylon filament composite yarns,

[0037] Color: Brown,

[0038] Dyeing process:

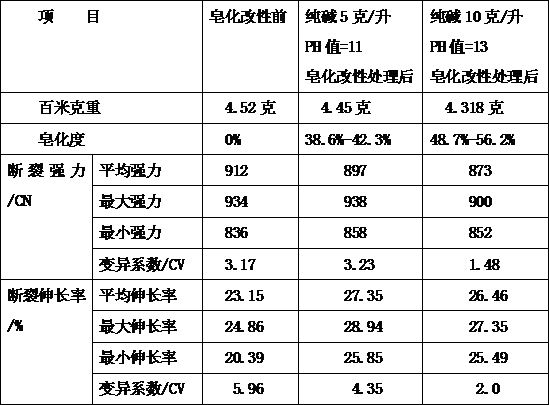

[0039] The first step: Soda ash 10 g / L, PH value = 13, saponification modification treatment;

[0040] Step Two: First Bath Reactive Dyeing:

[0041] Ratio of dyestuffs: reactive 3BS red 0.30%,

[0042] Active 3RS Yellow 0.75%,

[0043] Active BRF Blue 0.23%,

[0044] Yuan Mingfen 15%,

[0045] Soda ash 5%,

[0046] Neutralize and rinse after dyeing,

[0047] Second bath disperse, acid dye dyeing:

[0048] Proportion of dyestuffs: Disperse HSF01 Red 0.125%,

[0049] Disperse HSF01 yellow brown 0.94%,

[0050] Disperse HSF01 navy blue 0.1%,

[0051] Acid C-2B Red 0.335%,

[0052] Acidic C-2R Yellow 0.57%,

[0053] Acidic C-2R blue 0.255%,

[0054] Glacial acetic acid 0.5 g / L

[0055] Leveling agent 300W 0.5%,

[0056] Yuanming powder 5%,

[0057] Incubate at 98°C for 60 minutes.

[0058] Just wash with water after dyeing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com