Bamboo / polyester blended fabric and production process thereof

A polyester blending and fabric technology, applied in textiles, textiles, papermaking, fabrics, etc., can solve the problems of acid resistance, poor alkali resistance, low strength, and poor shape retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] [Example 1] Bamboo fiber and polyester blending (twist coefficient: 372)

[0014] Bamboo fiber (22.4tex (26 S )) blended with polyester (moisture-wicking fiber): 70 / 30 by weight

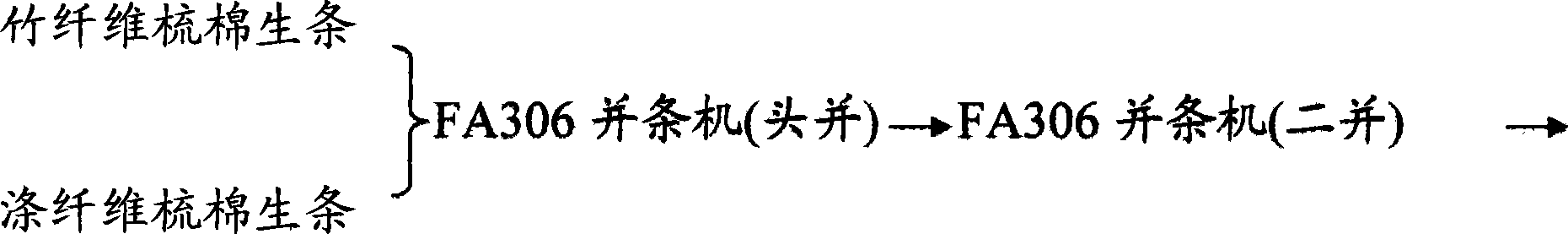

[0015] Prepare bamboo / polyester blended yarn according to the following process route:

[0016] Blowing → FA002 Grabber → FA016A Mixing Machine → FA106A Card Opener → FA046A Vibrating Cotton Box Feeder → FA141A Rolling Machine → FA201B Carding Machine →

[0017]

[0018] FA306 drawing frame (three parallels)→FA458A roving frame→FA506 spinning frame→GA013 winding machine

[0019] The moisture regain of each process is controlled at 10%-13% to improve spinnability.

Embodiment 2

[0020] [embodiment 2] make knitted fabric

[0021] Adopt the following process route to prepare bamboo fiber knitted double pique fabric:

[0022] Model: Jingwei single-sided machine JWE1163-34

[0023] Machine size: 28 needles / 25.4mm

[0024] Tube diameter: 34"

[0025] Raw material: 22.4tex (26 S ) bamboo / polyester (moisture wicking fiber) blended yarn (70 / 30)

[0026] Rough weight: 175g / m 2 Rough width: 120cm

[0027] Coil length: 26cm / 100pcs

[0028] Pin header: AB

[0029] Triangular row:

[0030] Yarn threading method: 4 roads and 1 cycle, each thread threading is the same (single yarn)

[0031] When weaving: the yarn feeding tension is generally controlled at 5-10g, which is more suitable; the design weight of the knitted fabric is controlled at the lower side (shrinkage is about 5%-8%).

[0032] Pure bamboo fiber has a shrinkage rate of 10-20%, low strength, especially low wet strength, and problems in printing and dyeing. The most prominent problem ...

Embodiment 3

[0033] [Example 3] Bamboo fiber and polyester blended (twist coefficient: 375)

[0034] Bamboo fiber and polyester blending ratio: 80 / 20 (weight), other is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com