Production process of sea island cotton plain weave fabric

A production process and plain weave technology, applied in the field of clothing fabrics, can solve the problems of poor stability, poor gloss durability, rough surface of the fabric, etc., and achieve the effect of improving stability and improving gloss durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

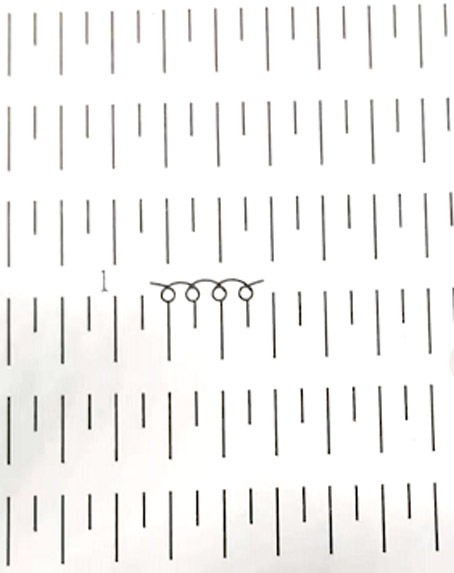

Image

Examples

Embodiment 1

[0034] A production process of sea-island cotton plain weave fabric, comprising the following steps:

[0035] S1. Weaving: sea-island cotton yarns with a cotton length of 38 mm are used to weave plain weave gray cloth according to the plain weave method; the gray cloth has a grammage of 180 g / ㎡.

[0036] S2. Embryo setting: put the gray cloth into a shaping machine for embryo setting; the temperature of the shaping machine is 200° C., and the speed is 30 m / min.

[0037] S3. Singeing: Put the gray cloth after the embryo setting into the singeing machine for singeing treatment, remove the fluff on the surface of the gray cloth; adopt four upper and lower burners, the burner temperature is 1100°C, and the speed is 40m / min.

[0038] S4, scouring: add scouring agent to scouring in water at 80°C for 40 minutes to boil the singed gray cloth;

[0039] S5. Epilating: put the scoured gray cloth into water at 70°C, add 0.01g / l depilatory agent, and depilate for 1 hour. After the depilat...

Embodiment 2

[0046] A production process of sea-island cotton plain weave fabric, comprising the following steps:

[0047] S1. Weaving: sea-island cotton yarns with a cotton length of 38 mm are used to weave plain weave gray cloth according to the plain weave method; the weight of the gray cloth is 200 g / ㎡.

[0048] S2. Embryo setting: put the gray cloth into a shaping machine for embryo setting; the temperature of the shaping machine is 220° C., and the speed is 40 m / min.

[0049] S3. Singeing: Put the gray cloth after the embryo setting into the singeing machine for singeing treatment, remove the fluff on the surface of the gray cloth; adopt four upper and lower burners, the burner temperature is 1400°C, and the speed is 50m / min.

[0050] S4, scouring: add scouring agent to scouring in water at 95°C for 60 minutes to boil the singed gray cloth into the cloth pot;

[0051] S5. Epilating: put the scoured gray cloth into water at 90°C, add 0.1g / l depilatory agent, and depilate for 2 hours. A...

Embodiment 3

[0058] A production process of sea-island cotton plain weave fabric, comprising the following steps:

[0059] S1. Weaving: sea-island cotton yarns with a cotton length of 38 mm are used to weave plain weave gray cloth according to the plain weave method; the weight of the gray cloth is 190 g / ㎡.

[0060] S2. Embryo fixing: Put the gray cloth into a shaping machine to fix the embryo; the temperature of the shaping machine is 210° C., and the speed is 35 m / min.

[0061] S3. Singeing: Put the gray cloth after the embryo setting into the singeing machine to perform singeing treatment to remove the fluff on the surface of the gray cloth; adopt four upper and lower burners, the burner temperature is 1200°C, and the speed is 45m / min.

[0062] S4, scouring: add scouring agent to scouring in water at 90°C for 50 minutes to boil the singed gray cloth;

[0063] S5. Epilating: Put the scoured gray cloth into water at 80°C, add 0.05g / l depilatory agent, and depilate for 1.5h. After the dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com