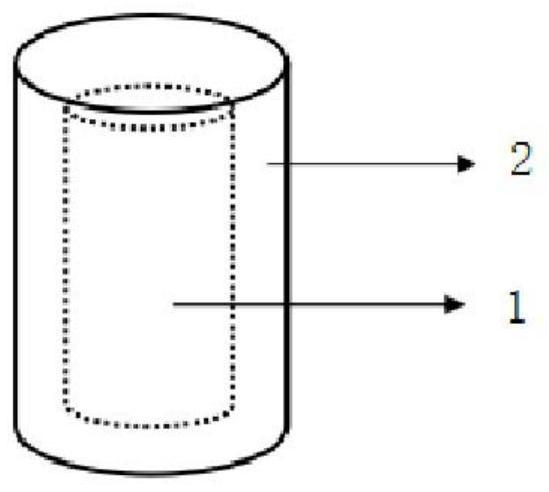

Hollow three-dimensional warm-keeping fabric and preparation method thereof

A three-dimensional effect and fabric technology, applied in textiles and papermaking, knitting, weft knitting, etc., can solve the problems of unsightly comfort, lack of three-dimensional effect, and heavy wearing, etc., to improve wettability and moisture absorption, good fluffy three-dimensional Good effect of feeling and warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a hollow three-dimensional thermal fabric, comprising the following steps:

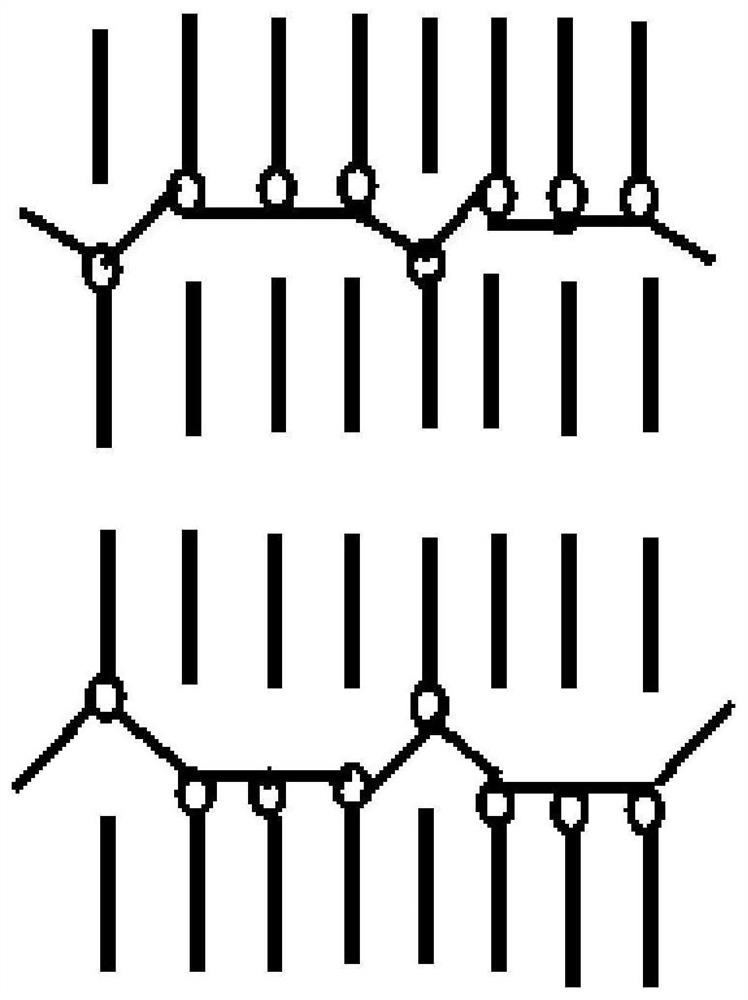

[0026] A. Fabric weaving: the yarn is woven into double-sided fabric through the double-sided knitting machine of the large circular knitting machine;

[0027] B. Dyeing and finishing process: degreasing and high-temperature boiling and bleaching are carried out to the fabric obtained in step A first, and then after acid deoxidation, dyeing process and softening treatment are carried out;

[0028] C. Post-finishing processing: the fabric obtained in step B is sequentially subjected to dehydration, edge opening, open width opening, loosening, fleece, and finished product setting treatment to obtain the hollow three-dimensional warm-keeping fabric.

[0029] Further, in step A, the yarns used in the double-sided fabric are 30S / 1BCI fine cotton yarn and 30S / 1 hollow polyester yarn.

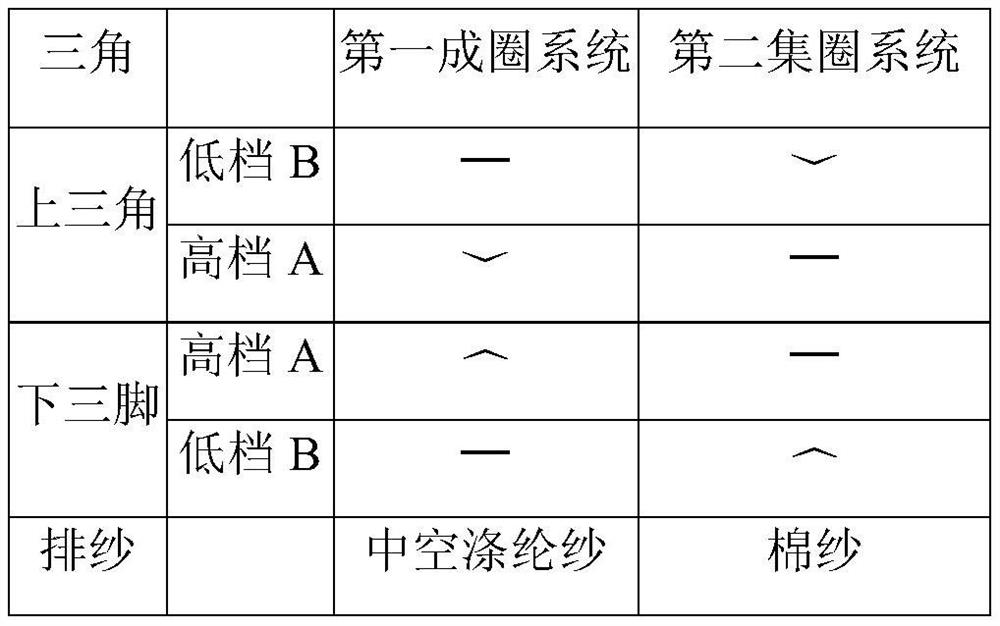

[0030] Further, the double-sided fabric fabric is composed of the first loop forming system ...

Embodiment 2

[0037] A method for preparing a hollow three-dimensional thermal fabric, comprising the following steps:

[0038] A. Fabric weaving: the yarn is woven into double-sided fabric through the double-sided knitting machine of the large circular knitting machine;

[0039] B. Dyeing and finishing process: degreasing and high-temperature boiling and bleaching are carried out to the fabric obtained in step A first, and then after acid deoxidation, dyeing process and softening treatment are carried out;

[0040] C. Post-finishing processing: the fabric obtained in step B is sequentially subjected to dehydration, edge opening, open width opening, loosening, fleece, and finished product setting treatment to obtain the hollow three-dimensional warm-keeping fabric.

[0041] Further, in step A, the yarns used in the double-sided fabric are 30S / 1BCI fine cotton yarn and 30S / 1 hollow polyester yarn.

[0042] Further, the double-sided fabric fabric is composed of the first loop forming system ...

Embodiment 3

[0049] A method for preparing a hollow three-dimensional thermal fabric, comprising the following steps:

[0050] A. Fabric weaving: the yarn is woven into double-sided fabric through the double-sided knitting machine of the large circular knitting machine;

[0051] B. Dyeing and finishing process: degreasing and high-temperature boiling and bleaching are carried out to the fabric obtained in step A first, and then after acid deoxidation, dyeing process and softening treatment are carried out;

[0052] C. Post-finishing processing: the fabric obtained in step B is sequentially subjected to dehydration, edge opening, open width opening, loosening, fleece, and finished product setting treatment to obtain the hollow three-dimensional warm-keeping fabric.

[0053] Further, in step A, the yarns used in the double-sided fabric are 30S / 1BCI fine cotton yarn and 30S / 1 hollow polyester yarn.

[0054] Further, the double-sided fabric fabric is composed of the first loop forming system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com