Method for preparing hollow wax mold by utilization of water-soluble wax

A water-soluble wax and wax mold technology, applied in manufacturing tools, casting equipment, molds, etc., can solve the problems of uneven thickness of wax molds, shrinkage of workpieces, and increased weight of workpieces, so as to reduce technical dependence and improve production efficiency. , the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

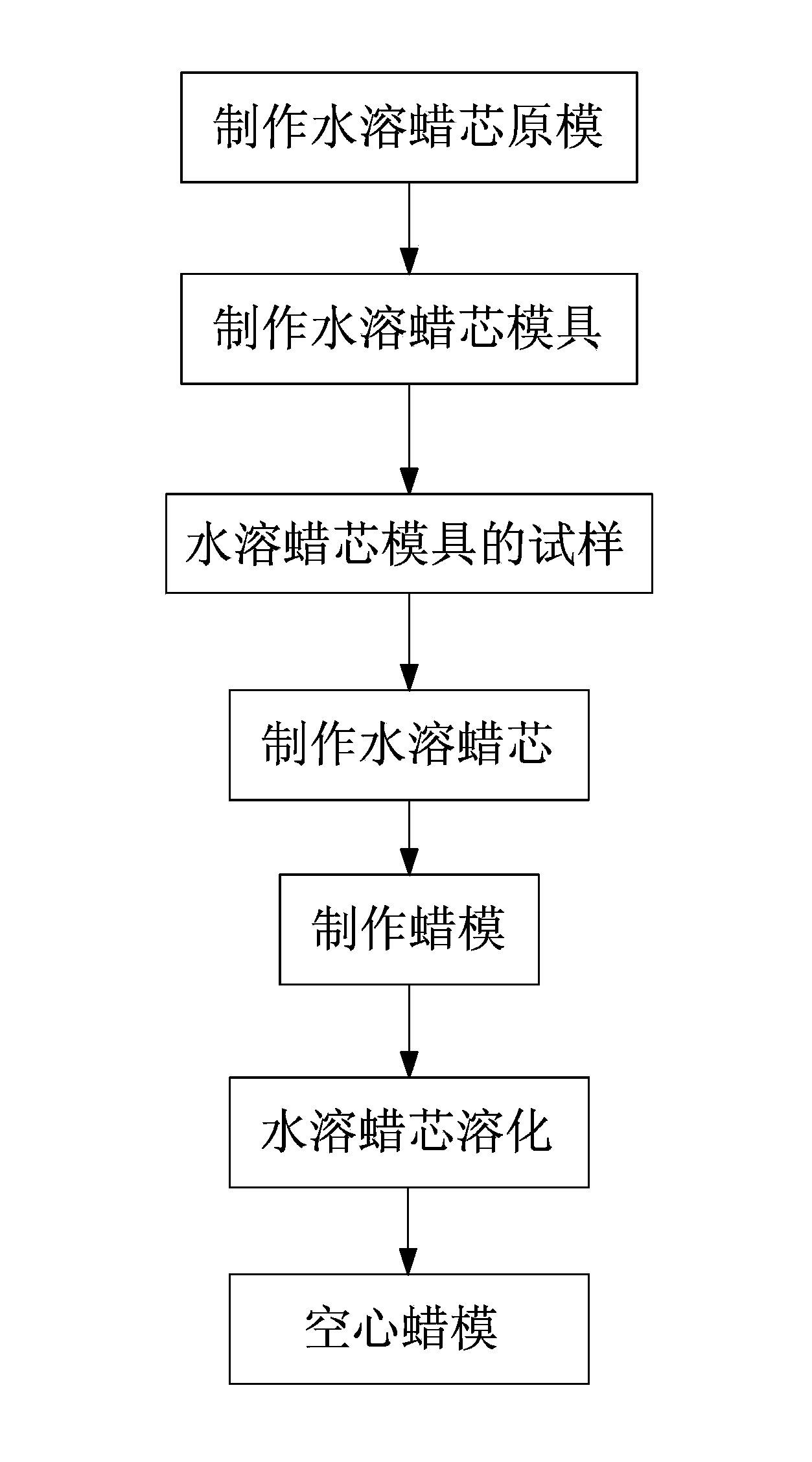

[0020] refer to figure 1 As shown, the present invention discloses a method of utilizing water-soluble wax to make a hollow wax model, the method comprising the following steps:

[0021] a, make the water-soluble wax core original model, make the water-soluble wax core original model according to the shape and weight requirements of the workpiece to be cast, the material of the water-soluble wax core original model is copper, and the water-soluble wax core original model is a copper plate, and the The outer dimension of the water-soluble wax core template is made according to the wall thickness of the workpiece. If the wall thickness of the workpiece is 1mm, the outer dimension of the water-soluble wax core template needs to be manually repaired by 1mm;

[0022] b. Mold making: put the copper plate or silver plate in the aluminum shell, pour the melted tin alloy liquid into the aluminum shell, and after the tin alloy liquid solidifies, open the mold to get the water-soluble wa...

Embodiment 2

[0028] refer to figure 1 As shown, the present invention discloses a method of utilizing water-soluble wax to make a hollow wax model, the method comprising the following steps:

[0029] a, make the water-soluble wax core original model, make the water-soluble wax core original model according to the shape and weight requirements of the workpiece to be cast, the material of the water-soluble wax core original model is copper, and the water-soluble wax core original model is a copper plate, and the The peripheral dimension of the water-soluble wax core template is made according to the wall thickness of the workpiece, and the wall thickness of the workpiece is 1.5mm, so the peripheral dimension of the water-soluble wax core template needs to be manually repaired and removed by 1.5mm;

[0030] b. Mold making: put the copper plate or silver plate in the aluminum shell, pour the melted tin alloy liquid into the aluminum shell, and after the tin alloy liquid solidifies, open the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com