Infusion pump and pump body bracket thereof

An infusion pump and pump body technology, applied in the field of medical devices, can solve the problems that metal debris affects the normal operation of the pump body, cannot guarantee high precision, size, structural error, etc., and achieves the elimination of the assembly process, easy size, and stable size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

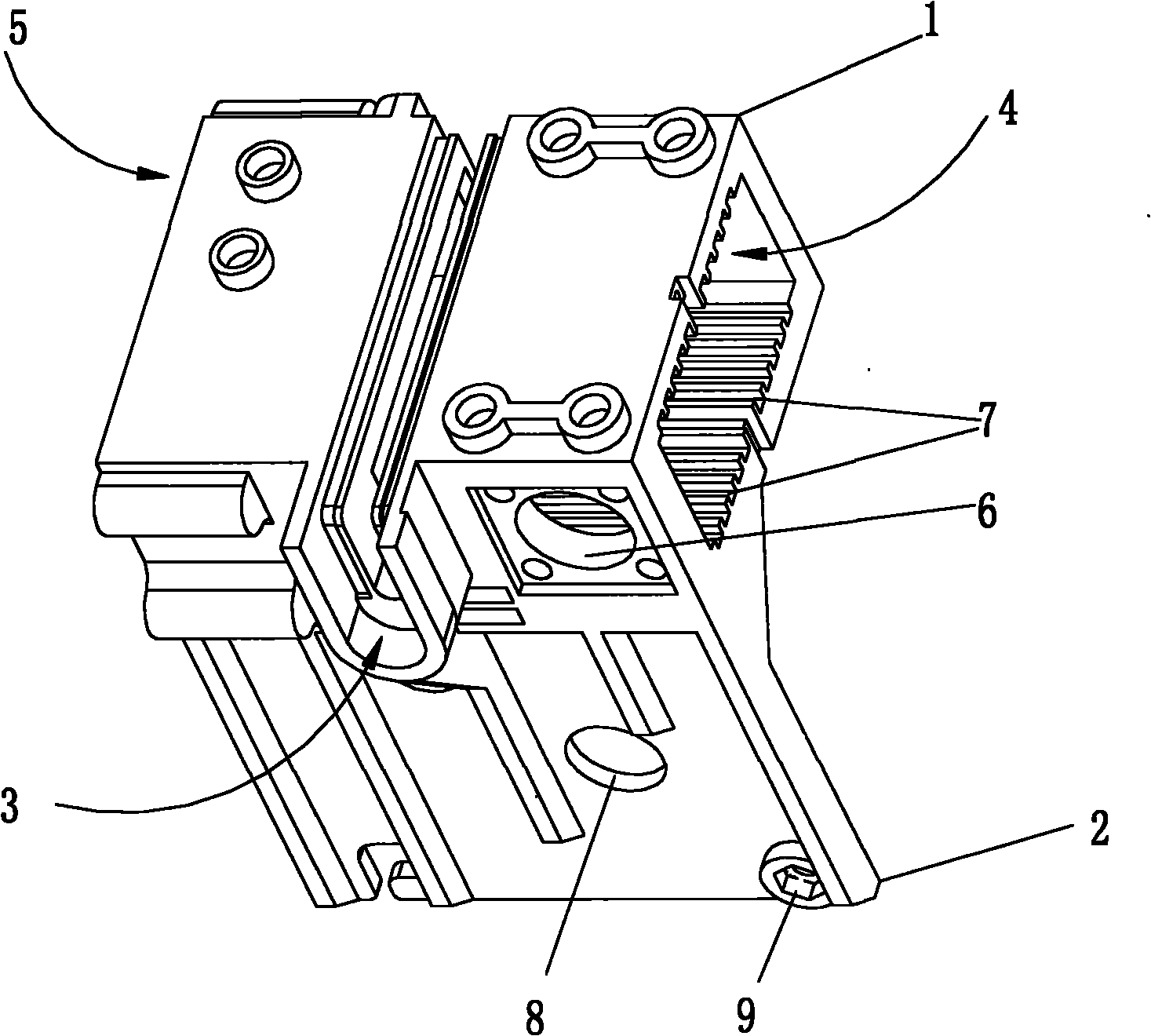

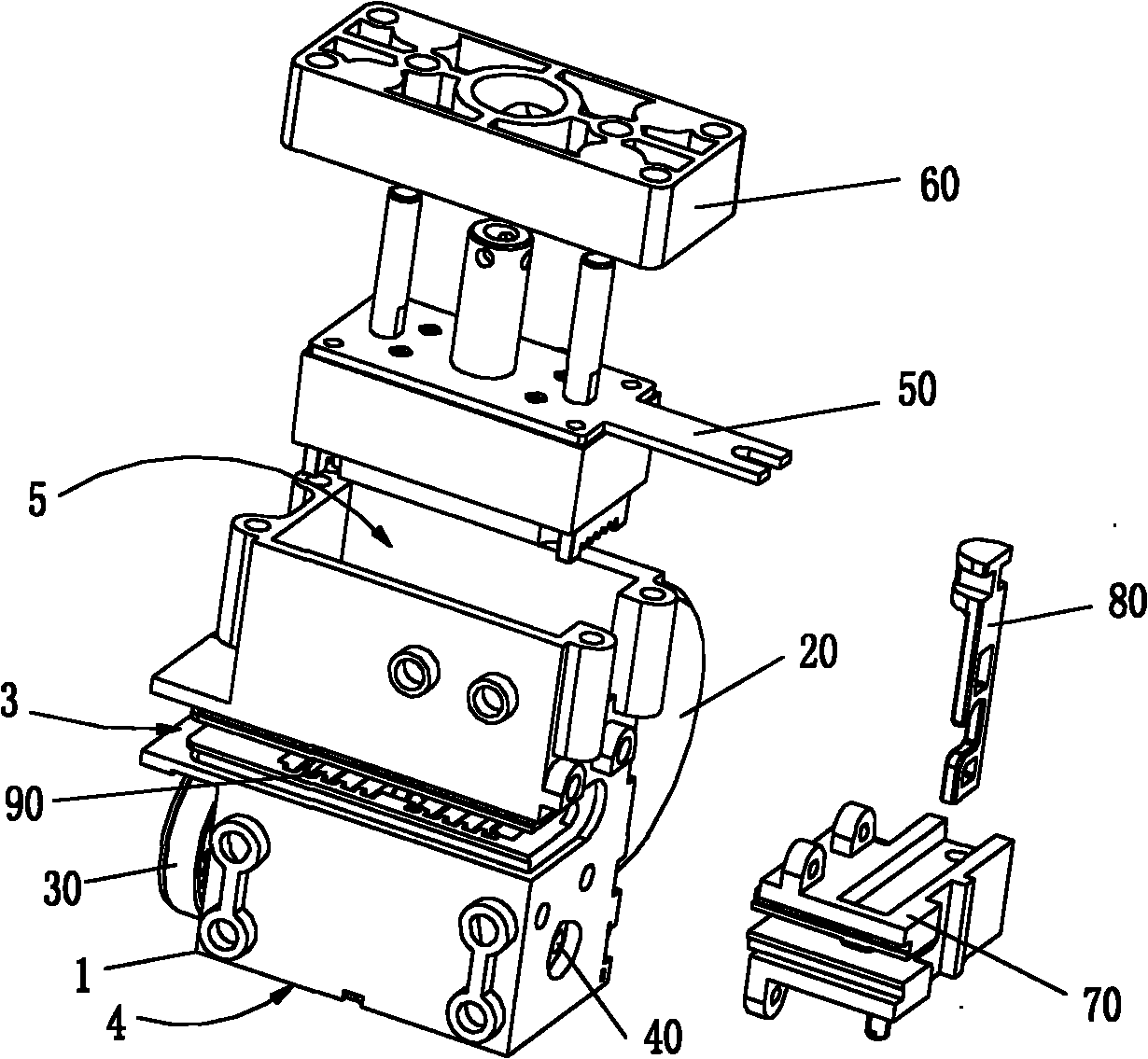

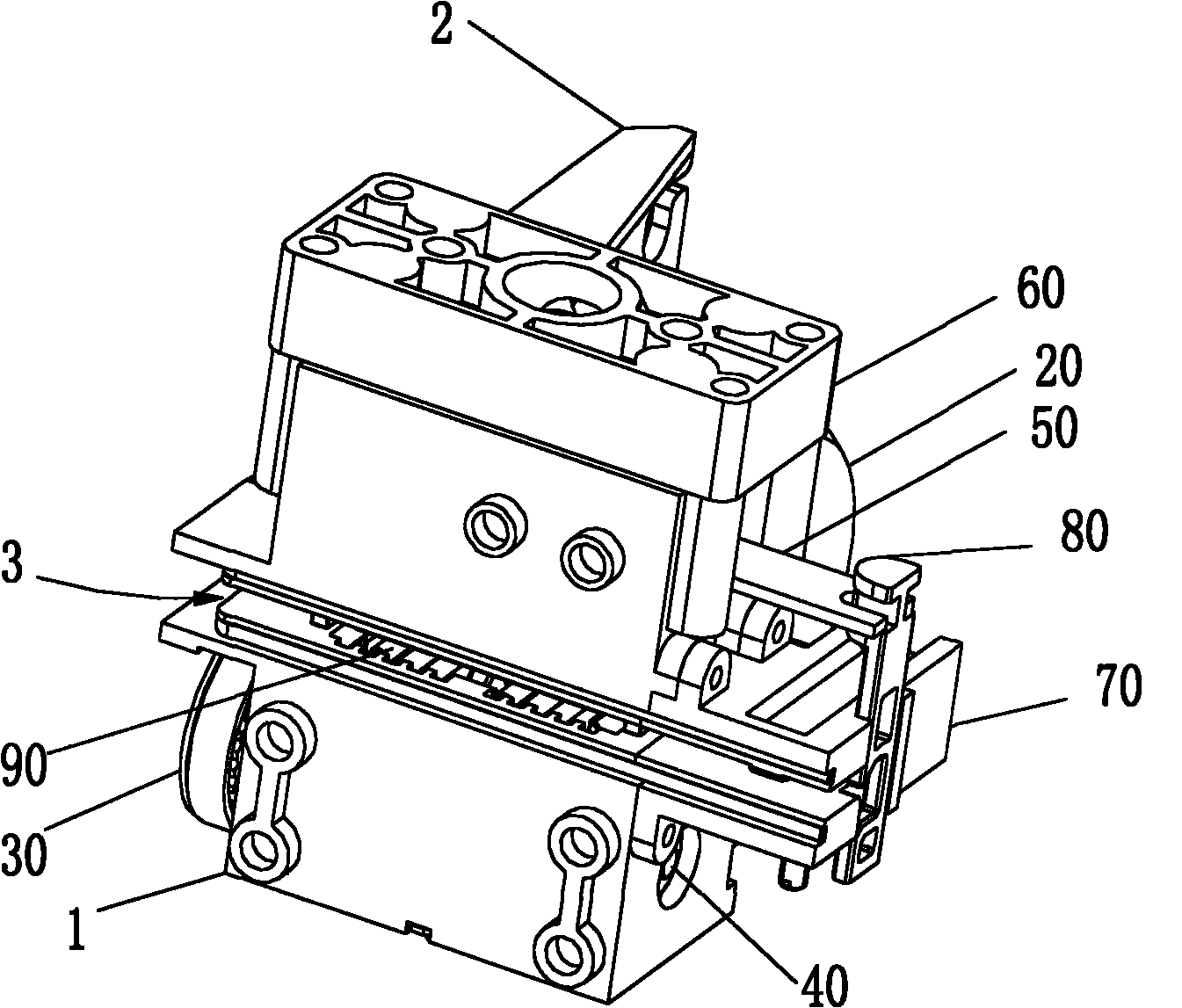

[0016] A pump body bracket of an infusion pump, such as figure 1 As shown, the pump body support is an integrated structure, including a peristaltic pump installation part 1, a motor installation part 2, and an infusion tube installation groove 3 is opened on it for passing an infusion hose.

[0017] The peristaltic pump installation part 1 is provided with a pump body installation chamber 4 and a pressure plate installation chamber 5 . The infusion tube installation groove 3 is located between the pump body installation chamber 4 and the pressure plate installation chamber 5 . A pump body bearing hole 6 and a vane slot 7 are opened on the side plate of the pump body installation chamber 4 . There are also other threaded holes for connecting and fixing the pump body and the pressure plate.

[0018] The motor mounting part 2 is a motor mounting plate, and the motor mounting plate is provided with a motor bearing hole 8 for passing through the motor shaft. The motor bearing ho...

specific Embodiment approach 2

[0023] A pump body bracket of an infusion pump, the integrated structure of which is the same as that of Embodiment 1, the difference is that: the pump body bracket is made of ABS material and integrally formed by injection molding process, the product has good consistency, and the shrinkage rate is 0.5% , the coefficient of friction is 0.28.

specific Embodiment approach 3

[0024] A pump body bracket of an infusion pump, its integrated structure is the same as that of the specific embodiment 1, the difference is that: the pump body bracket uses POM (Polyacetal, polyoxymethylene) material as the base material and is integrally formed by injection molding process, but the product The consistency is poor, the size is unstable, the shrinkage rate is 1.7%, and the friction coefficient is 0.13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com