Dark non-ironing washable pure cotton knitted fabric and preparation method and application thereof

A technology for knitted fabrics and production methods, which is applied in the direction of dyeing, fabric surface trimming, and textile material treatment, which can solve the problems of increased density of reactive dyes, large color changes, and decreased fabric strength, and achieve increased cellulose III content , the apparent color depth is deep, and the effect of increasing the ammonia removal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

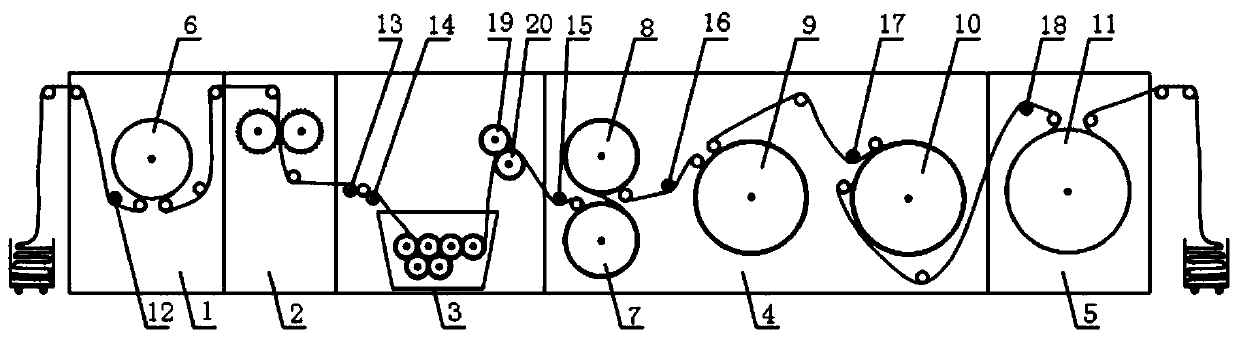

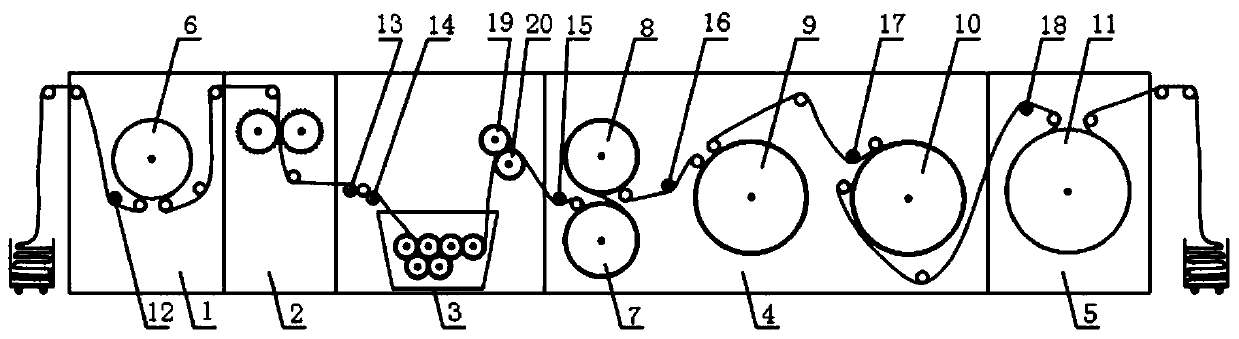

Method used

Image

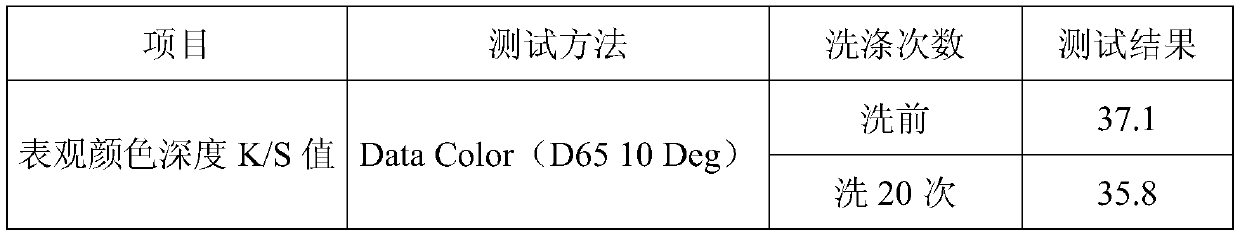

Examples

Embodiment 1

[0090] This embodiment provides a method for making a dark color non-ironing and washable pure cotton knitted fabric, wherein the method includes the following steps:

[0091] The yarn is sequentially subjected to blank weaving, scouring, enzyme washing, dyeing, liquid ammonia finishing, and resin setting to obtain the dark color non-ironing and washable pure cotton knitted fabric; in this embodiment, the knitted fabric is 30S / 1 pure Black cotton piqué knitted single face;

[0092] Scouring: Based on the total volume of the scouring solution used for scouring, the scouring solution contains 2g / L of refining agent Flowliq (Angao Chemical Co., Ltd.), 2g / L of caustic soda, 3g / L of H 2 o 2 solution, the scouring temperature is 95°C, and the treatment time is 50min;

[0093] Enzyme washing: the knitting obtained after scouring is placed in the enzyme treatment solution for treatment, and then the enzyme is inactivated;

[0094] Wherein, in terms of the total volume of the used e...

Embodiment 2

[0118] This embodiment provides a method for making a dark color non-ironing and washable pure cotton knitted fabric, wherein the method includes the following steps:

[0119] The yarn is sequentially subjected to blank weaving, scouring, enzyme washing, dyeing, liquid ammonia finishing, and resin setting to obtain the dark non-ironing and washable pure cotton knitted fabric; in this embodiment, the knitted fabric is 40S×2 pure Black cotton piqué knitted single face;

[0120] Scouring: Based on the total volume of the scouring solution used for scouring, the scouring solution contains 2g / L of refining agent Flowliq (Angao Chemical Co., Ltd.), 2g / L of caustic soda, 3g / L of H 2 o 2 solution, the scouring temperature is 95°C, and the treatment time is 50min;

[0121] Enzyme washing: the knitting obtained after scouring is placed in the enzyme treatment solution for treatment, and then the enzyme is inactivated;

[0122] Wherein, in terms of the total volume of the used enzyme ...

Embodiment 3

[0146] This embodiment provides a method for making a dark color non-ironing and washable pure cotton knitted fabric, wherein the method includes the following steps:

[0147] The yarn is sequentially subjected to blank weaving, scouring, enzyme washing, dyeing, liquid ammonia finishing, and resin setting to obtain the dark color non-ironing and washable pure cotton knitted fabric; in this embodiment, the knitted fabric is 50S / 1 pure Cotton double-sided Navy color knitted fabric;

[0148] Scouring: Based on the total volume of the scouring solution used for scouring, the scouring solution contains 2g / L of refining agent Flowliq (Angao Chemical Co., Ltd.), 2g / L of caustic soda, 3g / L of H 2 o 2 solution, the scouring temperature is 95°C, and the treatment time is 50min;

[0149] Enzyme washing: the knitting obtained after scouring is placed in the enzyme treatment solution for treatment, and then the enzyme is inactivated;

[0150] Wherein, in terms of the total volume of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com