Cooling and washing equipment for high-temperature coal gas

A technology for washing equipment and gas, which is applied in the manufacture of combustible gas, combustible gas purification, combustible gas purification/transformation, etc. It can solve the problems of ash in the synthesis gas, easy damage to the components of the washing and cooling chamber, and easy burn-through of the downpipe, etc., to achieve Strengthen cooling and dust removal, prolong the washing time, and protect from burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

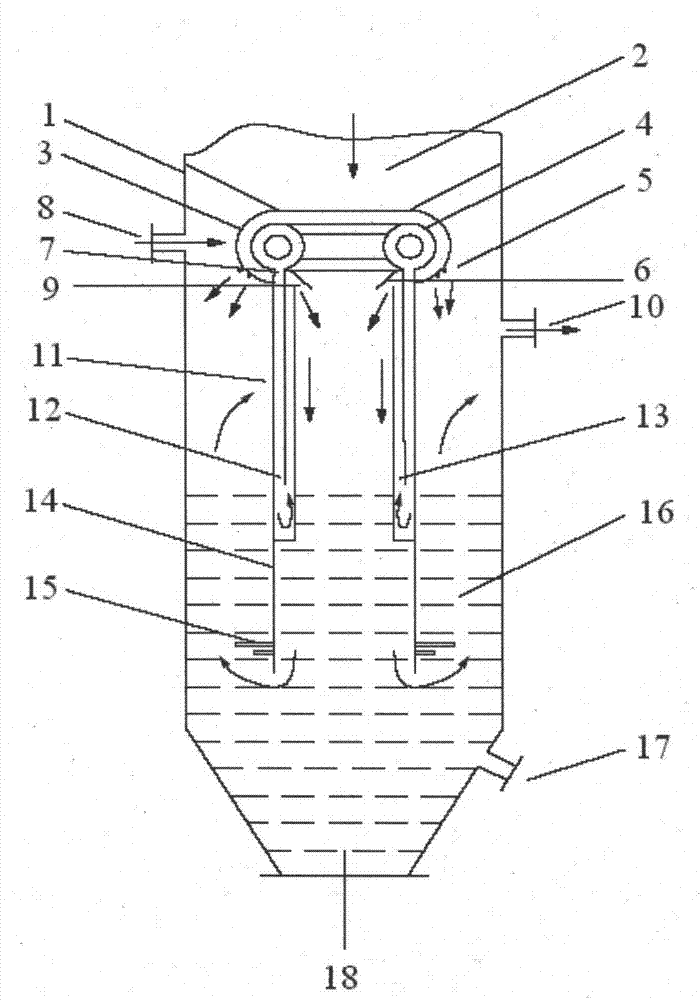

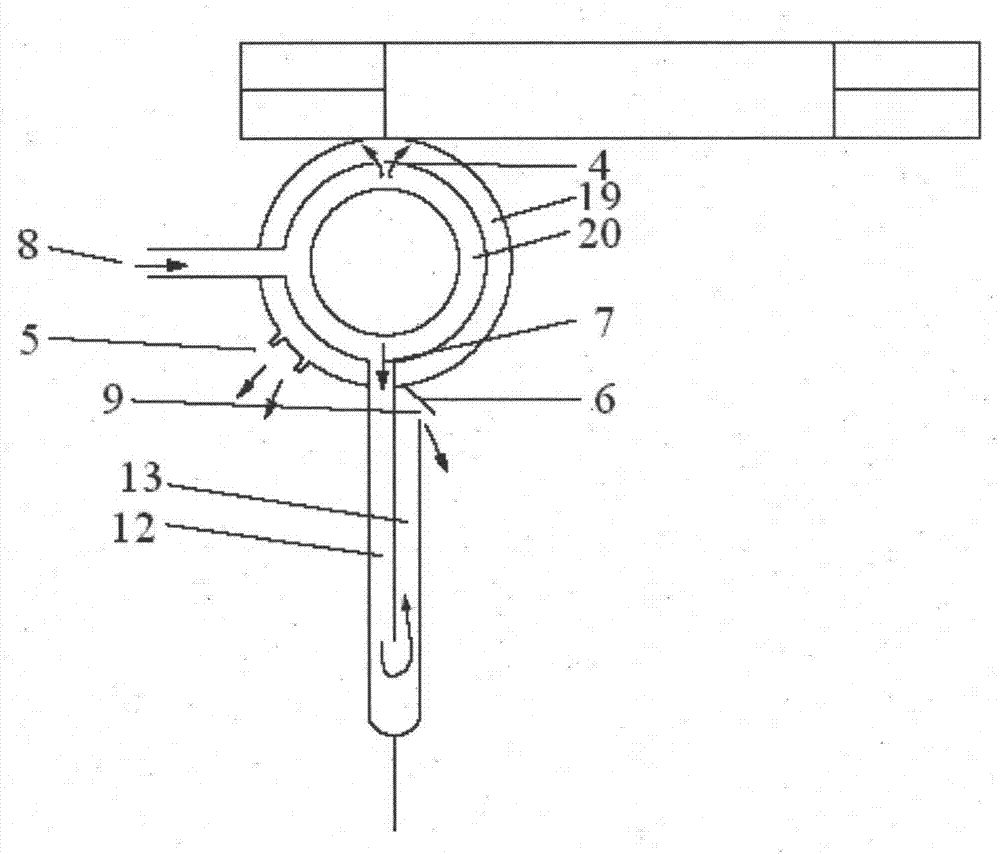

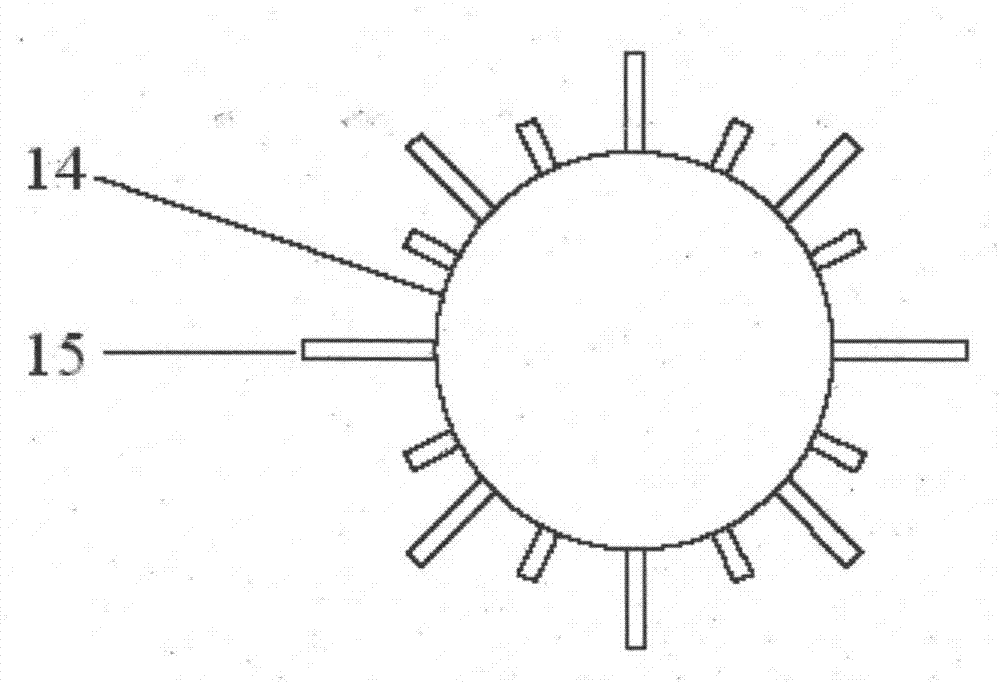

[0023] like Figure 1-3 As shown, it is a schematic structural diagram of a high-temperature gas cooling and washing equipment provided by the present invention, which includes a pressure-bearing shell 1, and the two sides of the pressure-bearing shell 1 are respectively provided with a washing water inlet 8 and a synthesis gas outlet 10, and the bottom is provided with Liquid outlet 17 and slag outlet 18. The upper part of the pressure housing 1 is the gasification chamber 2 and the bottom part is the slag pool 16 . The lower side of the gasification chamber 2 is connected with the water spray ring 3, the water spray ring 3 includes the water spray outer ring 19 and the water spray inner ring 20, the washing water inlet 8 communicates with the water spray inner ring 20; There is an opening 4, and the water spray inner ring 20 communicates with the water spray outer ring 19 through the opening 4; the lower side of the water spray ring 3 is connected to the downcomer, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com