Dish-washing machine

A dishwasher and washing pump technology, which is applied to the washing machine/washing machine for tableware, the parts of the washing machine/rinsing washing machine for tableware, cleaning equipment, etc. The effect of reducing energy consumption and extending washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

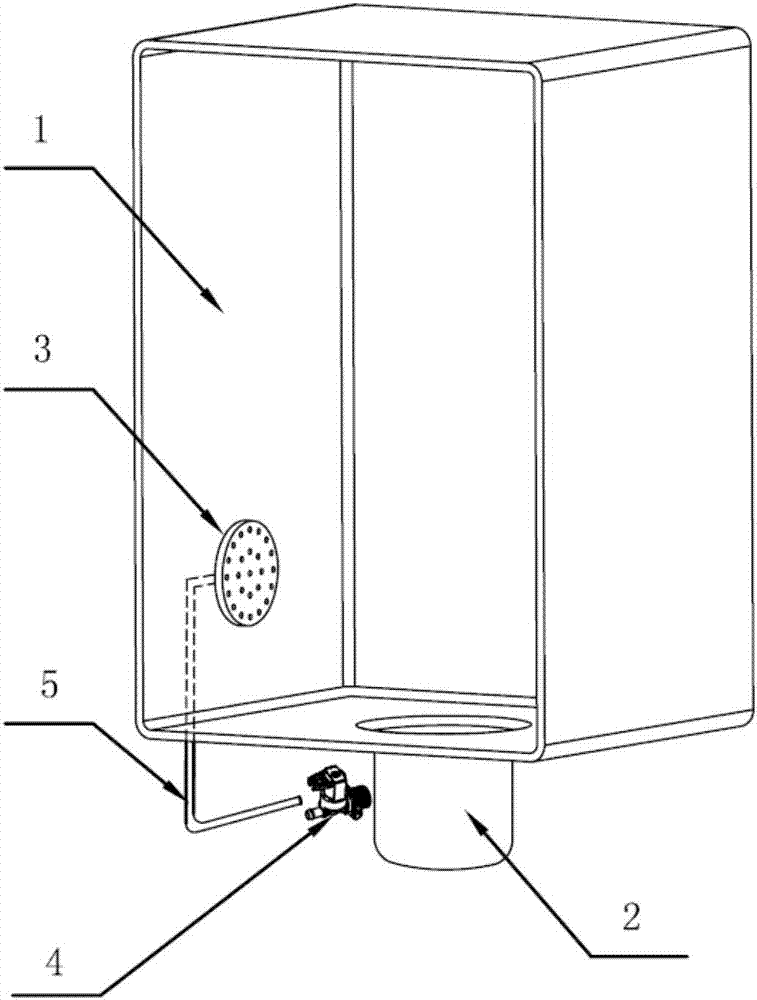

[0023] A kind of dishwasher is provided in this embodiment, such as figure 1 As shown, the dishwasher includes an inner container 1 and a water collection tank 2 arranged at the bottom of the inner container 1, at least one side wall of the inner container 1 is provided with a water inlet spray mechanism 3, and the water inlet spray mechanism 3 is connected with the water inlet solenoid valve 4 through the water inlet pipe 5 .

[0024] Wherein, a water inlet is provided on any side wall of the inner container 1 , and the water inlet is sealed and connected with the water inlet spray mechanism 3 . The water inlet spraying mechanism includes a spraying plate, and the spraying plate is densely covered with a plurality of water spraying holes. In this embodiment, the shape of the shower plate is circular, rectangular or elliptical. Of course, the structure of the shower plate in other embodiments is not limited by this embodiment, and can be in any shape.

[0025] Since the dish...

Embodiment 2

[0029] The difference between this embodiment and embodiment 1 is:

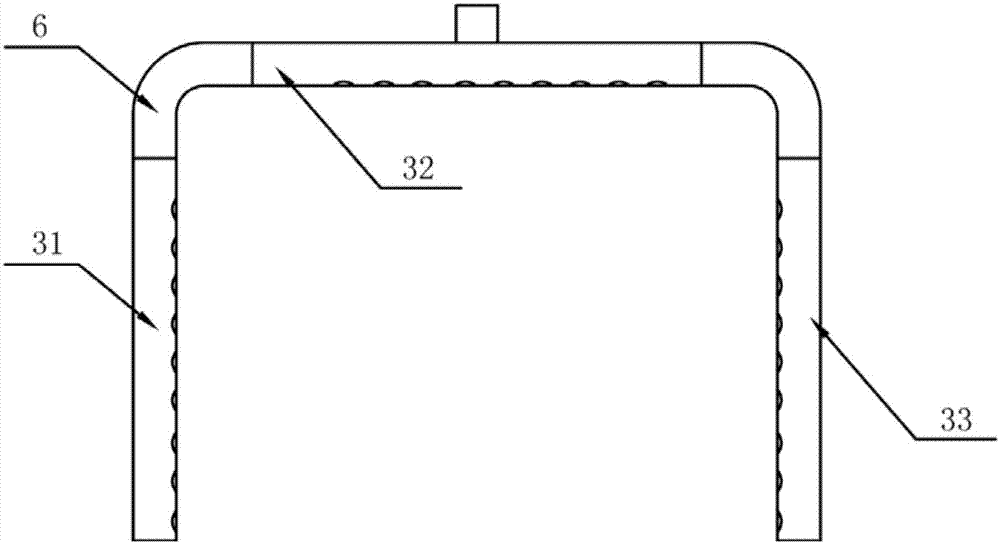

[0030] Please refer to figure 2 , the water inlet spraying mechanism comprises a tubular spraying arm, and the tubular spraying arm comprises a first tubular spraying arm 31, a second tubular spraying arm 32, a third tubular spraying arm respectively arranged on the side wall of the liner 1 The arm 33 and the second tubular spray arm 32 communicate with the first tubular spray arm 31 and the third tubular spray arm 33 through corner joints respectively. Wherein the second tubular spray arm 32 is connected with the water inlet pipe. Of course, it can also be arranged that the first tubular spray arm 31 or the third tubular spray arm 33 is connected to the water inlet pipe.

[0031] In order to spray the positions that are not easy to be sprayed during the washing process, in this embodiment, the first tubular spray arm 31, the second tubular spray arm 32, and the third tubular spray arm 33 are fixedly arran...

Embodiment 3

[0034] The difference between this embodiment and embodiment 2 is:

[0035] A three-way pipe (not shown) is also arranged between the water inlet spray mechanism 3 and the water inlet solenoid valve 4, and any two side walls of the inner tank 1 are provided with a water inlet, and the water inlet spray mechanism 3 includes two spray plates, and each spray plate is arranged at the water inlet of the inner tank 1.

[0036] The purpose of setting the three-way pipe is to divide the water in the water inlet pipe 5 and enter the inner container respectively, so that the water entering the inner container can be sprayed from different directions to wash bowls and dishes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com