Methane purifier with quickly mutually-changing desulfurized bottle and pressure meter device

A technology of pressure gauge and purifier, which is applied in the field of biogas purification and pressure gauge device, can solve the problems of failure of desulfurization device, complicated refueling operation, and no consideration of regeneration or replacement of desulfurizer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment the present invention is further described as follows:

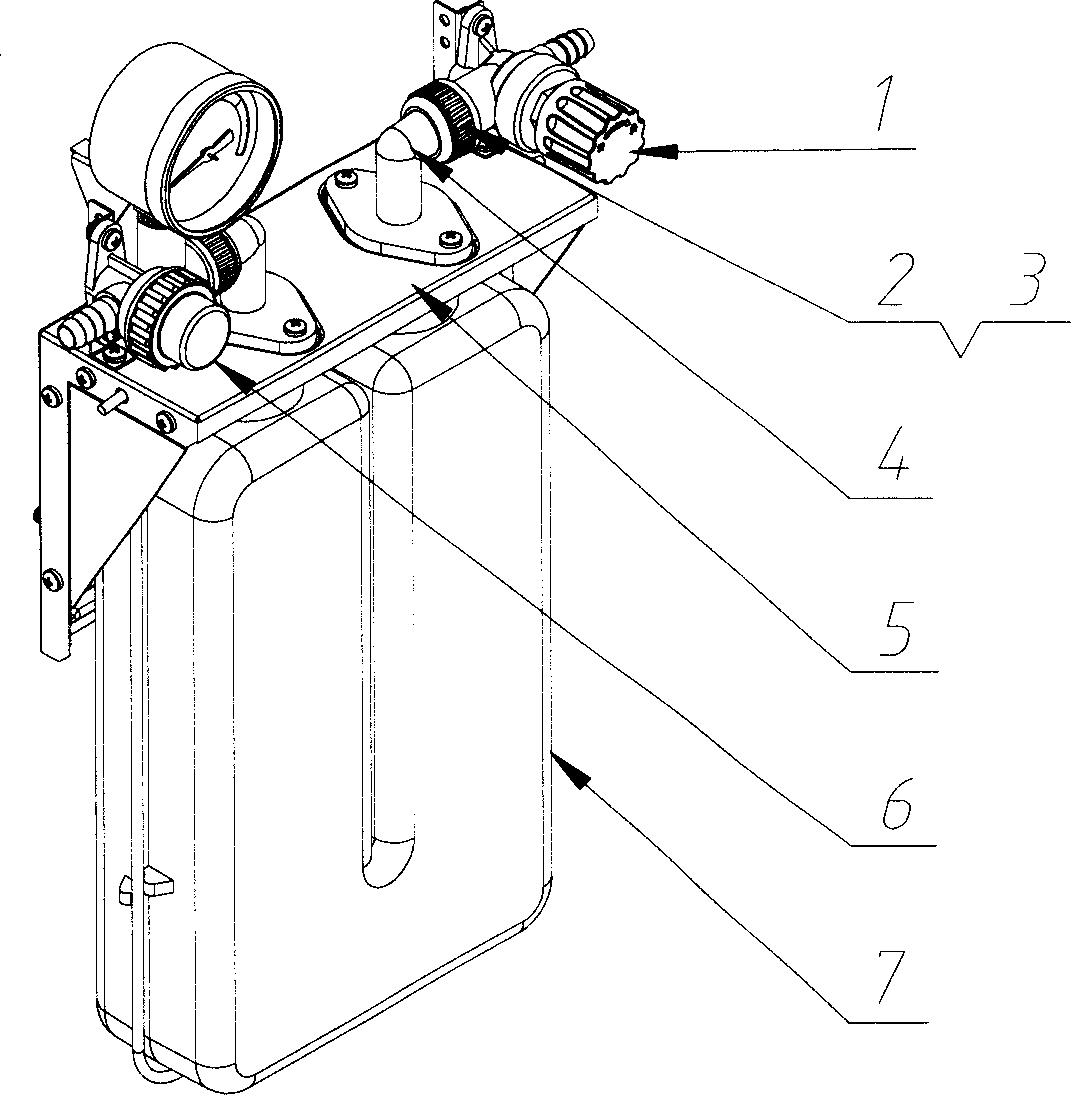

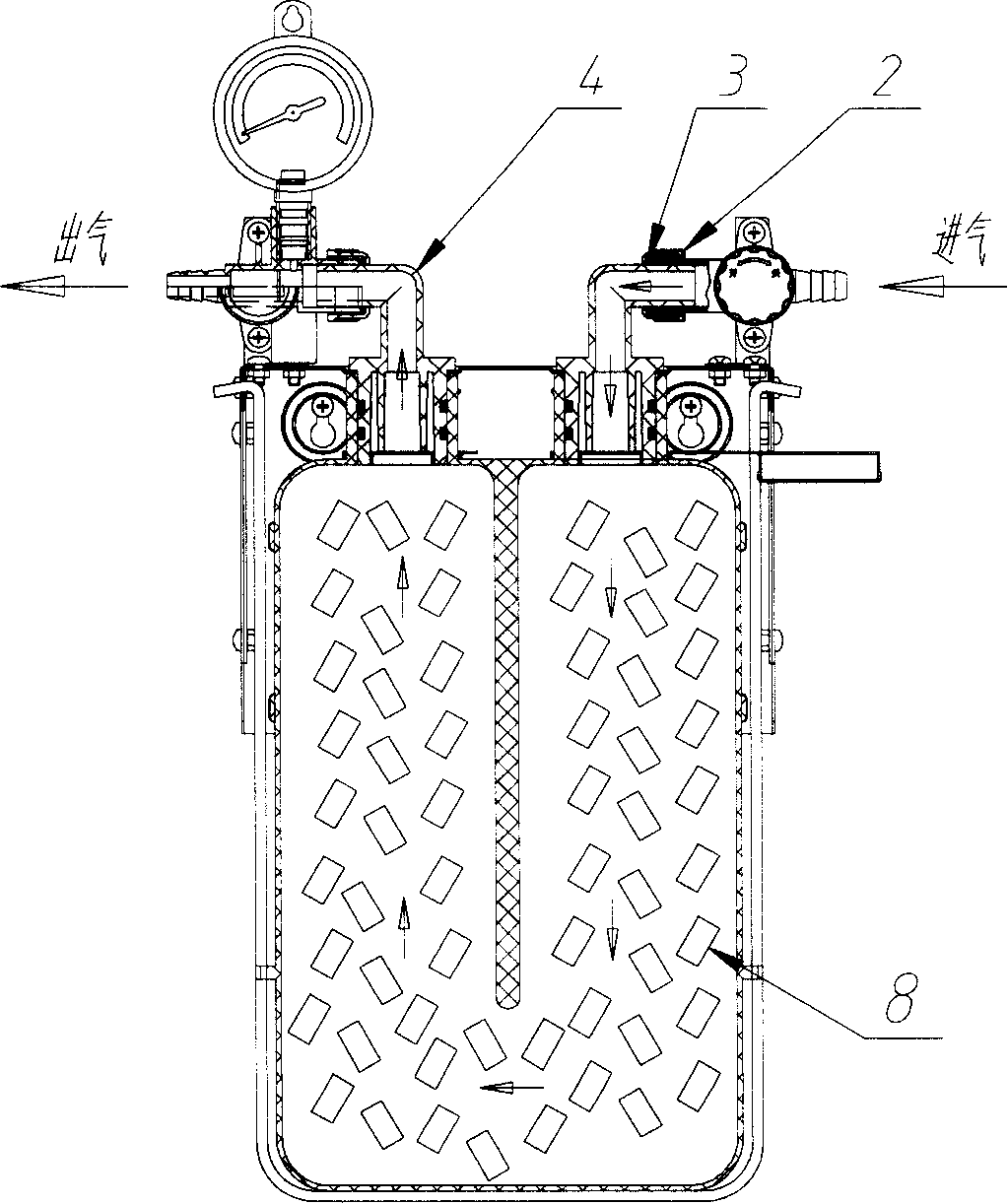

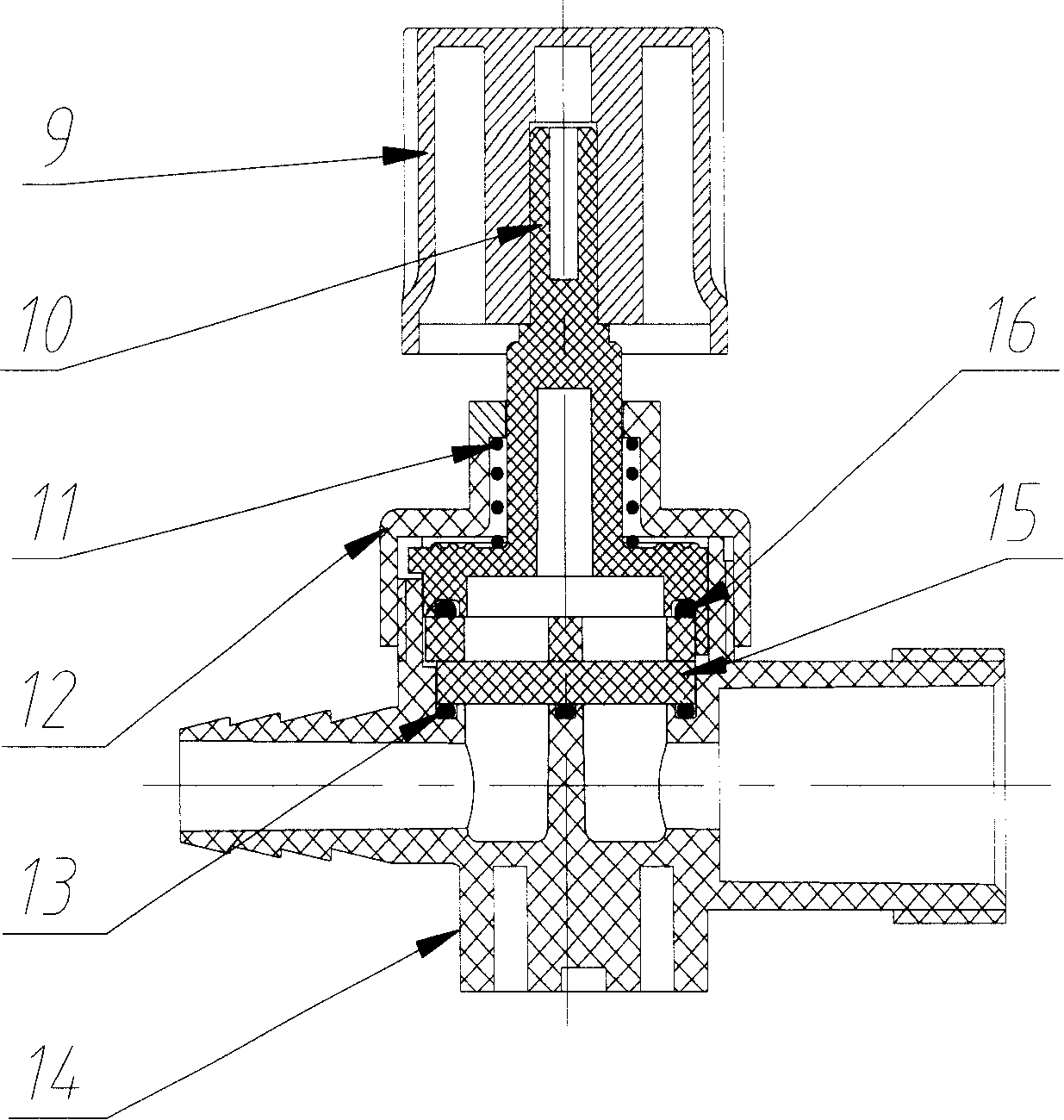

[0027] The present invention is mainly composed of a control valve part 1, a bottle stopper part 4, a desulfurizer bracket part 5, a display part 6, and a desulfurization bottle part 7. See figure 1 , figure 2 , the two cork parts 4 are symmetrically installed on the main body of the desulfurizer bracket part 5 with screws, and the wire interface of the valve body 14 of the regulating valve part 1 and the short pipe of the cork 17 of the cork part 2 on one side use M22*2.5 plastic nuts 2 and φ16 sealing sleeve 3 are connected, and fixed on the small bracket 20 on one side of the desulfurizer bracket part 5 with screws; Connect the pipe with M22*2.5 plastic nut 2 and φ16 sealing sleeve 3, and fix it on the small bracket 20 on the other side of the desulfurizer bracket part 5 with screws; then fix the pressure gauge fixing card 23 on the small bracket 20 on this side with screws ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com