Preparation method of precious metal anode for PCB horizontal electroplating

A technology of precious metals and anodes, applied in the direction of electrodes, metal material coating technology, liquid chemical plating, etc., can solve the problems of increased consumption of additives, achieve the effects of improved conversion efficiency, reduced anode cost, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

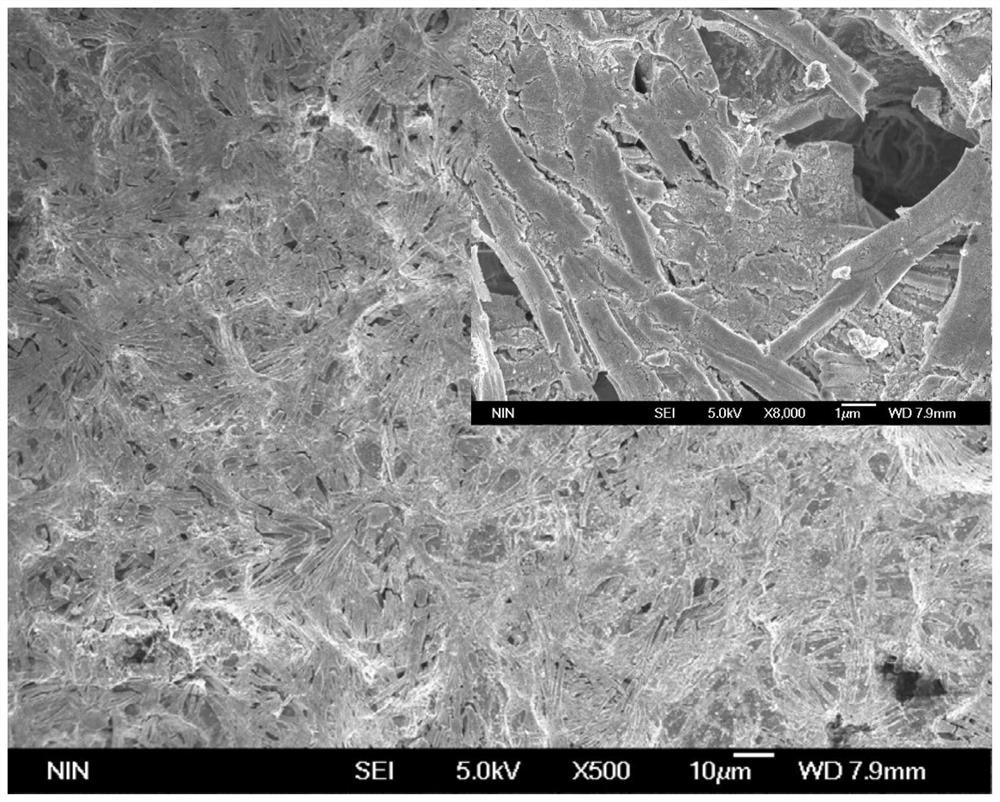

[0033] The preparation method of the noble metal anode used for PCB horizontal electroplating provided by the present invention, the coating of the titanium anode is an Ir-Ta system noble metal coating containing a cobalt source, and the specific preparation steps are as follows:

[0034] S1. Titanium substrate pretreatment: degrease, degrease, pickle and etch the surface of the titanium substrate with a cleaning agent;

[0035] S2. Preparation of active liquid: accurately weigh a certain amount of chloroiridic acid and dissolve it in n-butanol solvent, stir at room temperature until completely dissolved to form solution A; accurately weigh a certain amount of tantalum pentachloride n-butanol solution to dissolve In n-butanol solvent, stir at room temperature until completely dissolved to form solution B; accurately weigh a certain amount of CoCl 2 ·6H 2 O is dissolved in n-butanol solvent, stirred at room temperature until completely dissolved to form solution C; solution A,...

Embodiment 1

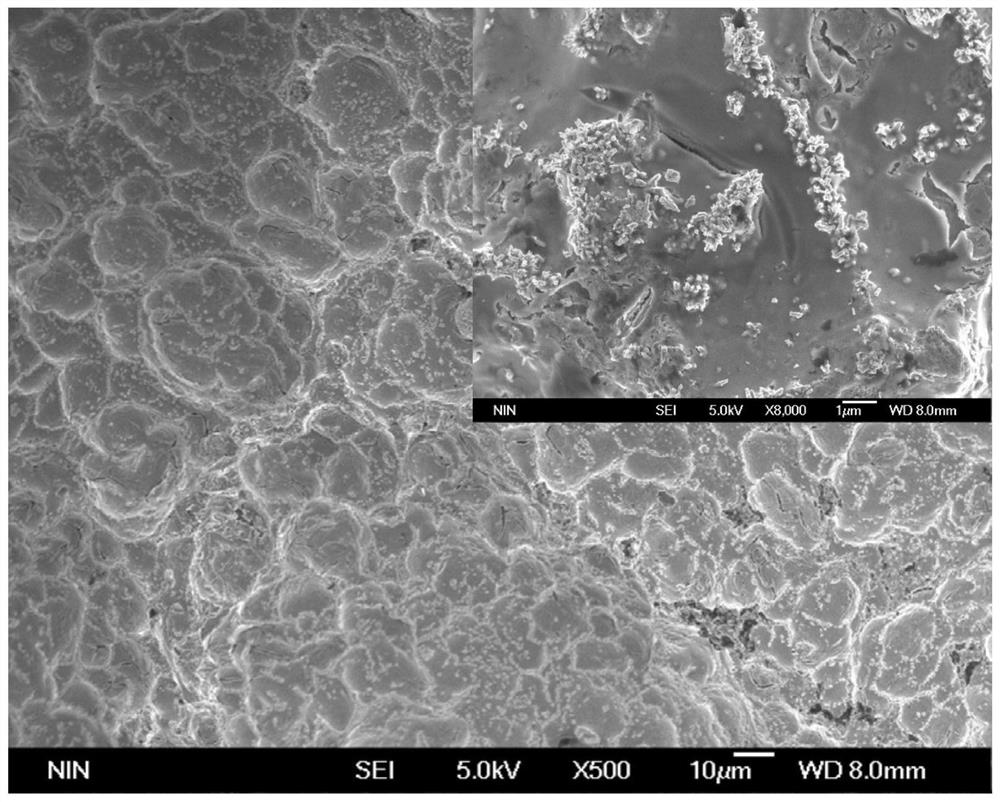

[0038] This example provides a method for preparing a noble metal anode for horizontal electroplating of PCBs, and the scanning electron microscope image of the anode for horizontal electroplating of PCBs prepared by it can be found in figure 1 . The preparation method specifically includes:

[0039] S1. Titanium substrate pretreatment: degreasing and degreasing the surface of the titanium substrate, sandblasting, thermal shaping, pickling and other treatments;

[0040] S2, prepare active liquid: accurately weigh a certain amount of chloroiridic acid and dissolve it in n-butanol solvent (the metal ion concentration is 0.3mol / L), stir at room temperature until completely dissolved to form solution A; accurately weigh a certain amount The n-butanol solution of tantalum pentachloride is dissolved in n-butanol solvent (concentration of metal ions is 0.3mol / L), is stirred at room temperature until completely dissolving, forms solution B; Solution A, solution B are Ir according to ...

Embodiment 2

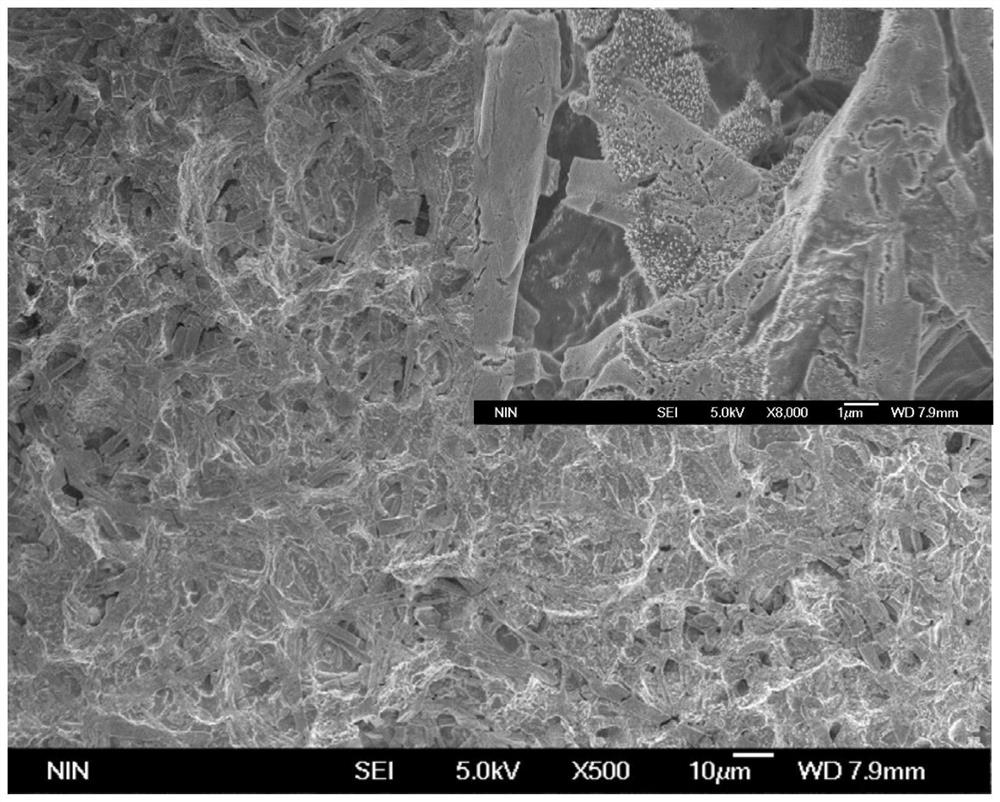

[0043] This example provides a method for preparing a noble metal anode for horizontal electroplating of PCBs, and the scanning electron microscope image of the anode for horizontal electroplating of PCBs prepared by it can be found in figure 2 . The preparation method specifically includes:

[0044] S1. Titanium substrate pretreatment: degreasing and degreasing the surface of the titanium substrate, sandblasting, thermal shaping, pickling and other treatments;

[0045] S2, prepare active liquid: accurately weigh a certain amount of chloroiridic acid and dissolve it in n-butanol solvent (the metal ion concentration is 0.3mol / L), stir at room temperature until completely dissolved to form solution A; accurately weigh a certain amount The n-butanol solution of tantalum pentachloride is dissolved in n-butanol solvent (the metal ion concentration is 0.3mol / L), stirred at room temperature until completely dissolved to form solution B; accurately weigh a certain amount of CoCl 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com