Preparation method of titanium anode for water treatment

A titanium anode and water treatment technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high cost, achieve low cost, reduce production cost, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

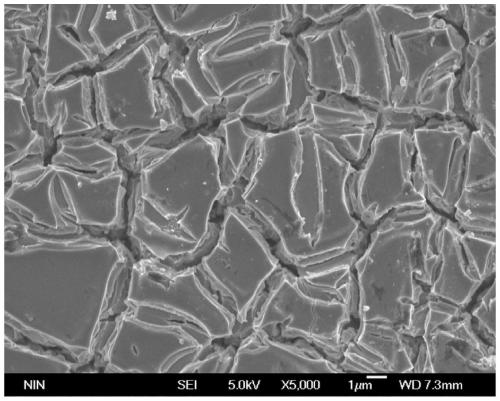

[0055] like figure 1 As shown, Step1: Degreasing and degreasing the titanium substrate, sandblasting, thermal calibration, acid etching, and preparing the titanium substrate for painting.

[0056]Step2: Accurately weigh 0.427g RuCl 3 ·3H 2 O, dissolved in a mixed solvent of absolute ethanol and ethylene glycol (V 乙醇 :V 乙二醇 =9:1), stirred at room temperature until completely dissolved to form solution A; added 1.6762 g of butyl titanate and an appropriate amount of concentrated hydrochloric acid (volume ratio 10%) to solution A, stirred at room temperature until completely dissolved to form a solution B; Save for later use.

[0057] Step3: Apply solution B evenly on the treated titanium substrate, let it dry naturally for 2 minutes to spread the coating evenly, place it in an oven at 120°C to completely evaporate the solvent, then place it in a sintering furnace at 450°C, and sinter for 10 minutes , take it out, and let it cool down to room temperature naturally. Repeat t...

Embodiment 2

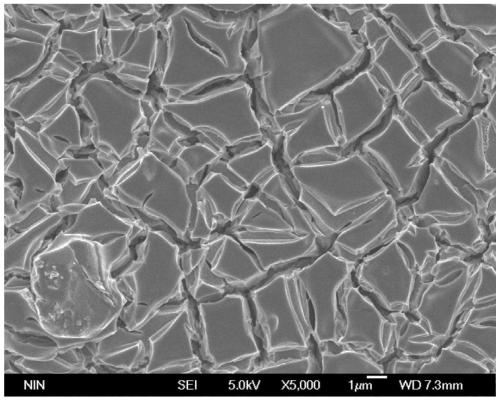

[0059] refer to figure 2 , Step1: Degreasing and degreasing the titanium substrate, sandblasting, thermal calibration, acid etching, and preparing the titanium substrate for painting.

[0060] Step2: Accurately weigh 0.427g RuCl 3 ·3H 2 O, dissolved in a mixed solvent of absolute ethanol and ethylene glycol (V 乙醇 :V 乙二醇 =9:1), stirred at room temperature until completely dissolved to form solution A; added 1.6762 g of butyl titanate and an appropriate amount of concentrated hydrochloric acid (volume ratio 10%) to solution A, stirred at room temperature until completely dissolved to form a solution B; Save for later use.

[0061] Step3: Apply solution B evenly on the treated titanium substrate, let it dry naturally for 2 minutes to spread the coating evenly, place it in an oven at 120°C to completely evaporate the solvent, then sinter it in a sintering furnace at 350°C for 5 minutes, and then Place it in a sintering furnace at 450°C, sinter for 5 minutes, take it out, and...

Embodiment 3

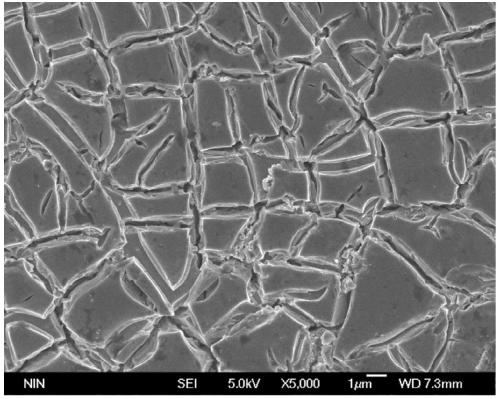

[0063] Step1: Degrease and degrease the titanium substrate, sandblasting, thermal calibration, acid etching, and prepare the titanium substrate for painting.

[0064] Step2: Accurately weigh 0.427g RuCl 3 ·3H 2 O, dissolved in a mixed solvent of absolute ethanol and ethylene glycol (V 乙醇 :V 乙二醇 =9:1), stirred at room temperature until completely dissolved to form solution A; in solution A, add 1.6762g butyl titanate (n Ru :n Ti =1:3) and an appropriate amount of concentrated hydrochloric acid (volume ratio 10%), stirred at room temperature until completely dissolved to form solution B; 0.0129g WCl was added in solution B, stirred at room temperature until completely dissolved to form solution C, preserved ,stand-by.

[0065] Step3: Apply solution B evenly on the treated titanium substrate, let it dry naturally for 2 minutes to spread the coating evenly, place it in an oven at 120°C to completely evaporate the solvent, then sinter it in a sintering furnace at 350°C for 5 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com