Preparation of tube wall layer number-controllable nano-carbon tube

A carbon nanotube and tube wall technology is applied in the field of preparation of carbon nanotubes, which can solve problems such as unfavorable research on the characteristics of multi-walled carbon nanotubes, and achieve the effects of simple operation, simple equipment, and cheap and easy-to-obtain raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

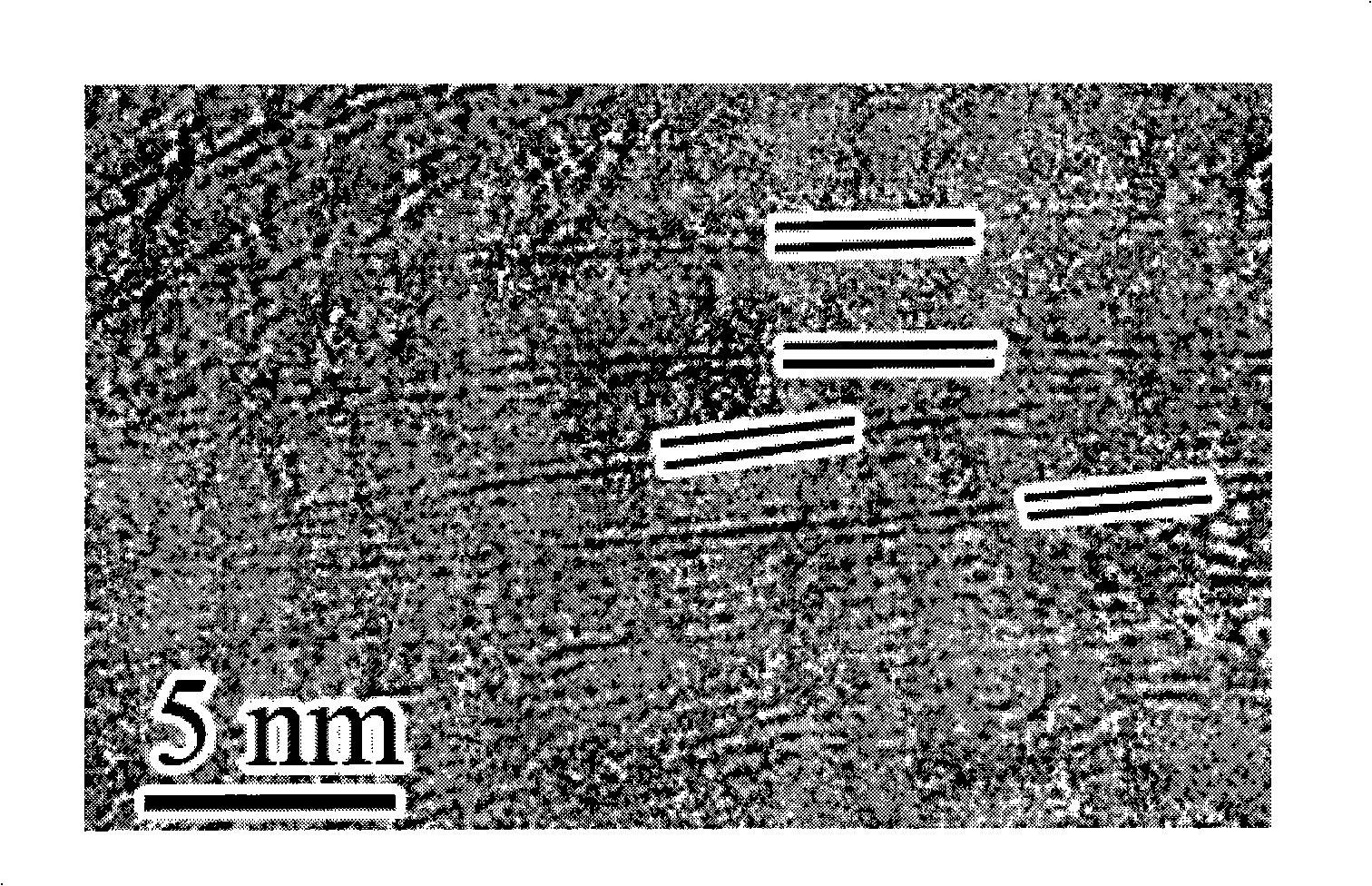

Embodiment 1

[0024] Prepare double-walled carbon nanotubes, comprising the following steps:

[0025] (1) According to the molar ratio Fe:Mo:Al=1:0.1:13, take by weight polyethylene glycol-200 of iron nitrate nonahydrate, aluminum nitrate, ammonium molybdate tetrahydrate and the amount of substance equivalent to aluminum nitrate, dissolve Stir in deionized water until a transparent solution is formed, and control the molar concentration of aluminum nitrate to 0.1 mol / l. Then heat at 95°C to evaporate water to form a foamy colloid, then burn the foamy colloid violently at 550°C in air for 15 minutes, then cool and grind to make catalyst powder.

[0026] (2) heat-treat the quartz reaction chamber of the CVD device in air at 1000° C. for 30 minutes to remove residual carbon components, and then pass through 500 sccm of nitrogen to remove the air.

[0027] (3) Spread the prepared 0.100g catalyst powder evenly in the catalyst chamber, put it into a constant temperature quartz reaction chamber, ...

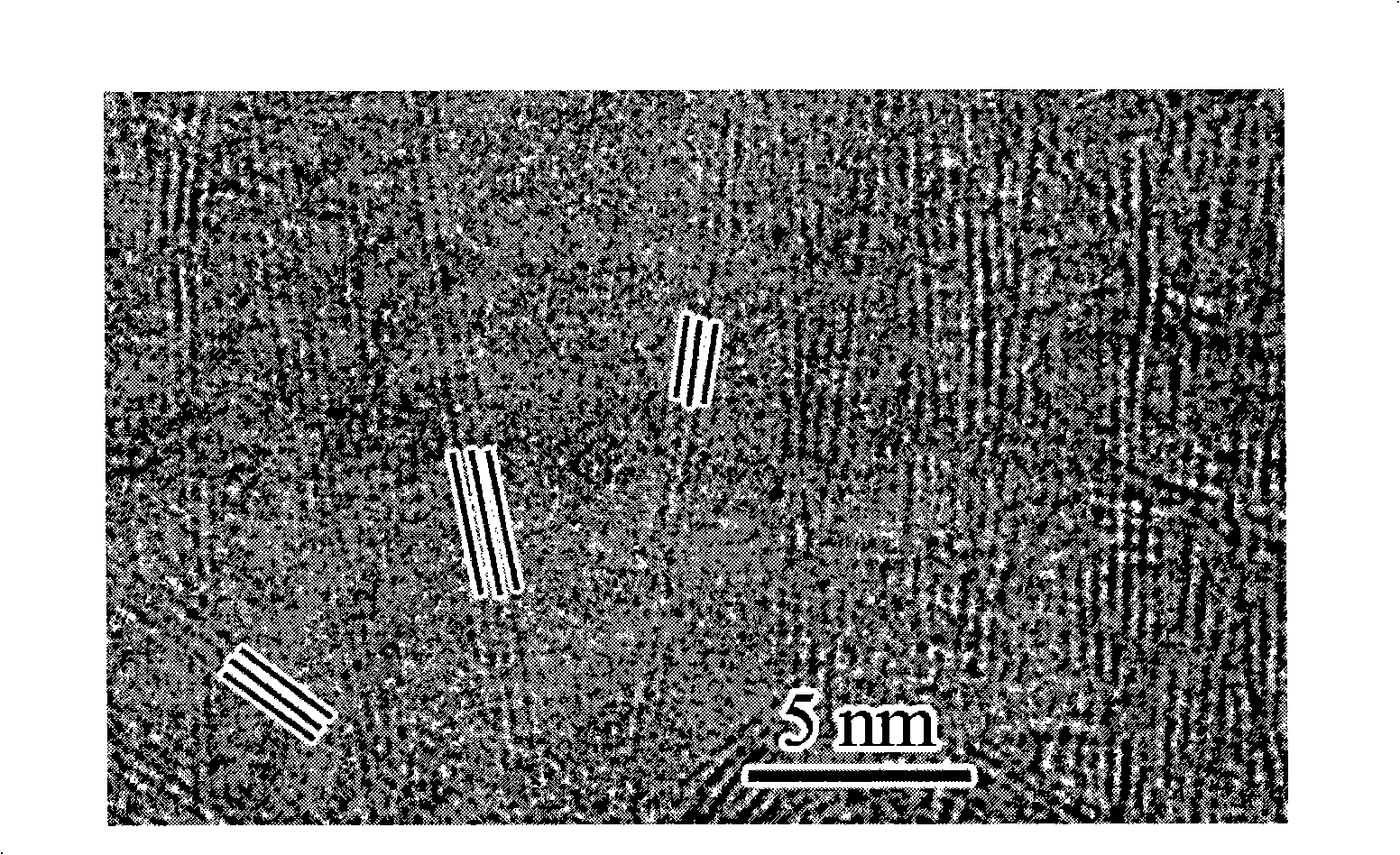

Embodiment 2

[0031] Prepare three-walled carbon nanotubes, comprising the following steps:

[0032] (1) Add 3.0g of magnesium ethylate to 200ml of deionized water, stir at 80°C for 30min, then add iron nitrate and ammonium molybdate according to the atomic ratio of Fe:Mo:Mg=1:0.5:7, and continue stirring for 1h , and then dissolve citric acid equivalent to half of the amount of magnesium element, and stir for 30 minutes to form a solution.

[0033] (2) Put the above mixed solution in a watch glass and place it on a partition, put the partition into a cold trap of a freeze dryer, cool down to -50° C., and freeze the above solution. After the solution is completely frozen, the separators are placed on the control panel of the drying room, and the vacuum degree of the drying room is evacuated to 10Pa, and then the sample is freeze-dried at -30°C for 24 hours to remove more than 90% of the water in the sample. Then slowly raise the temperature of the separator to -10°C, keep it warm for 2 hou...

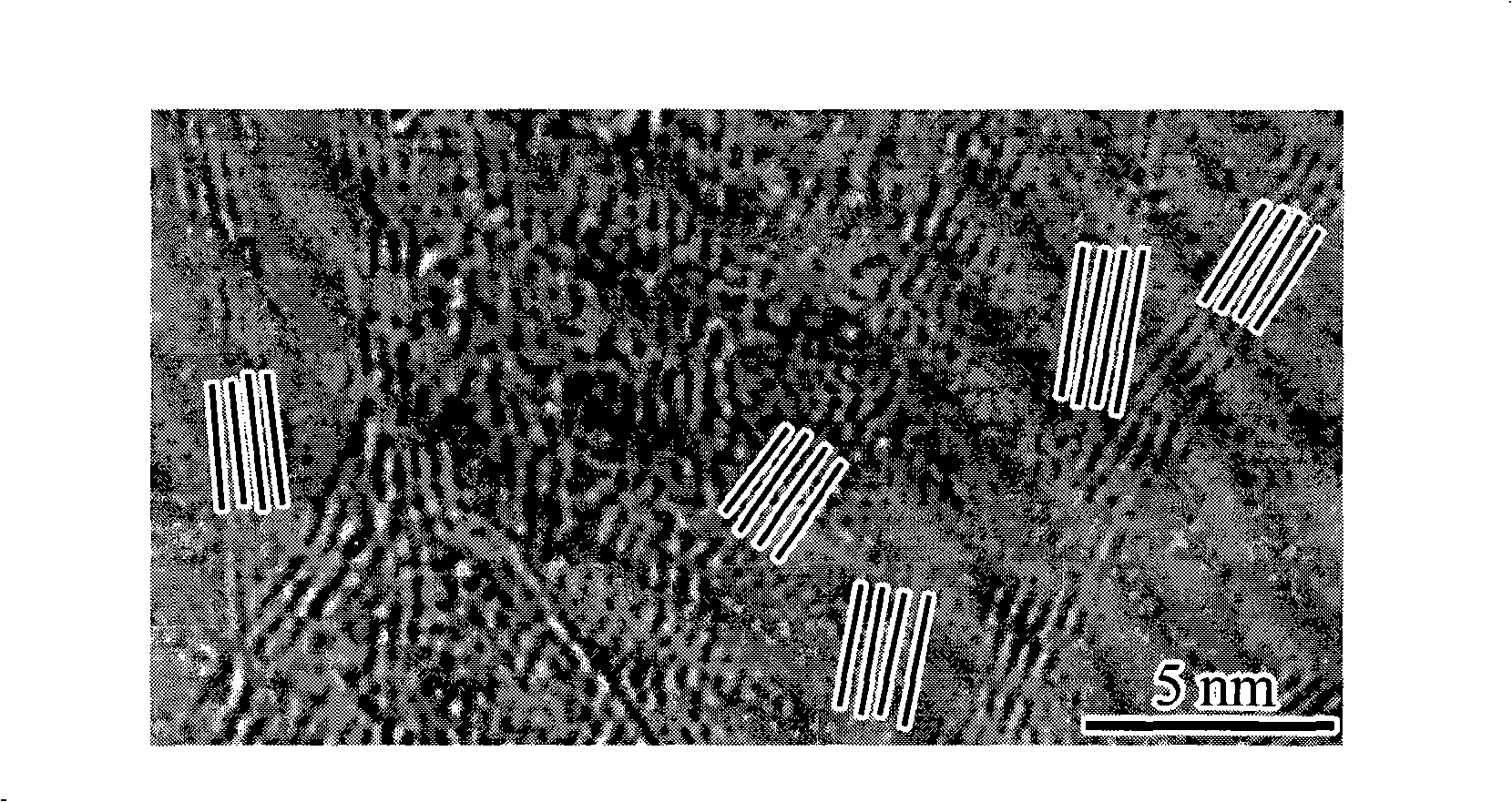

Embodiment 3

[0038] Prepare four-walled carbon nanotubes, comprising the following steps:

[0039] (1) Add 3.0g of magnesium ethylate to 200ml of deionized water, stir at 80°C for 30min, then add iron nitrate nonahydrate and ammonium molybdate according to the atomic ratio of Fe:Mo:Mg=1.2:0.8:3, and continue Stir for 1 h, then dissolve ethylenediamine equivalent to 1 / 20 of the amount of magnesium element, and stir for 30 min to form a solution.

[0040] (2) Put the above mixed solution in a watch glass and place it on a partition, put the partition into a cold trap of a freeze dryer, cool down to -50° C., and freeze the above solution. After the solution is completely frozen, the separators are placed on the control panel of the drying room, and the vacuum degree of the drying room is evacuated to 10Pa, and then the sample is freeze-dried at -30°C for 24 hours to remove more than 90% of the water in the sample. Then slowly raise the temperature of the separator to -10°C, keep it warm for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com