Composite separation membrane preparation equipment

A separation membrane and equipment technology, which is applied in the field of equipment for preparing composite separation membranes by interfacial polymerization, can solve the problems of easily damaged surface, uncompactness, and inability to guarantee uniform content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

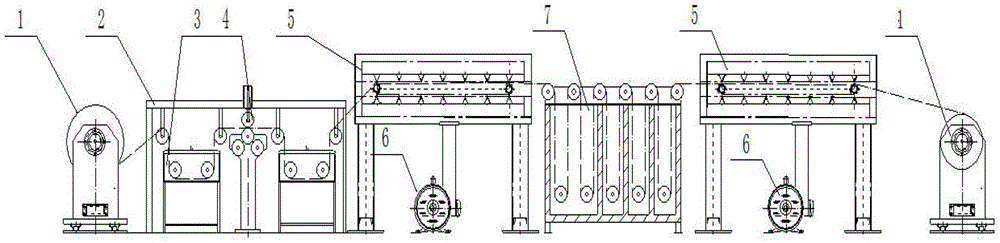

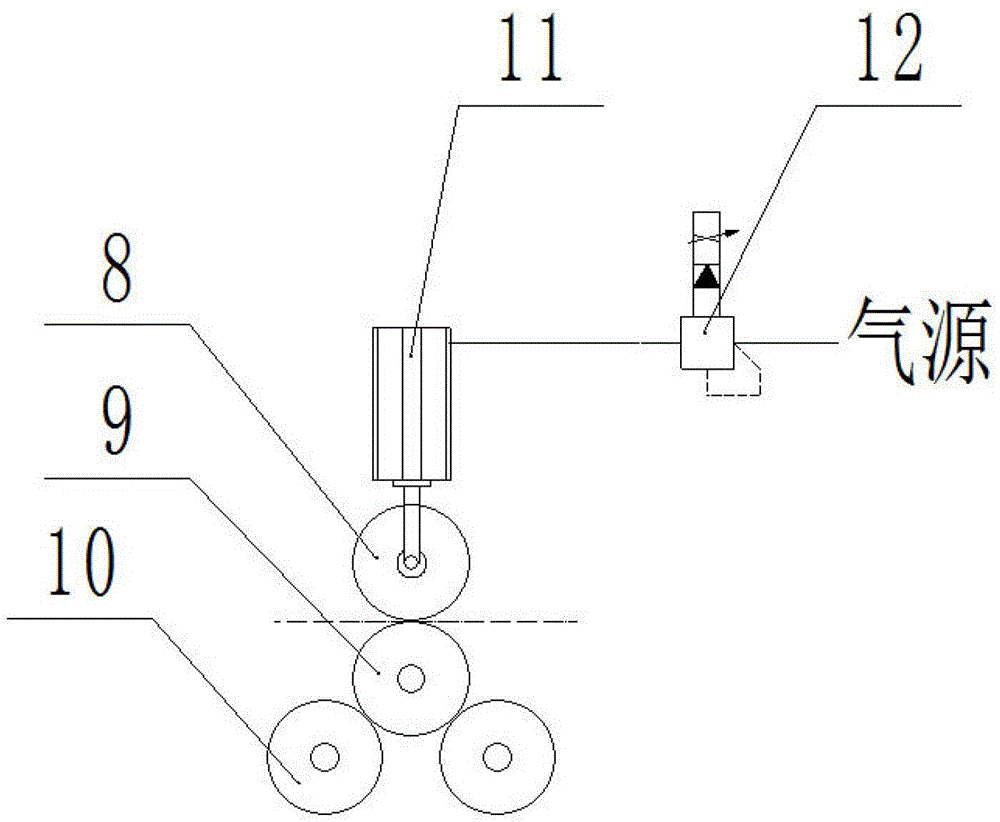

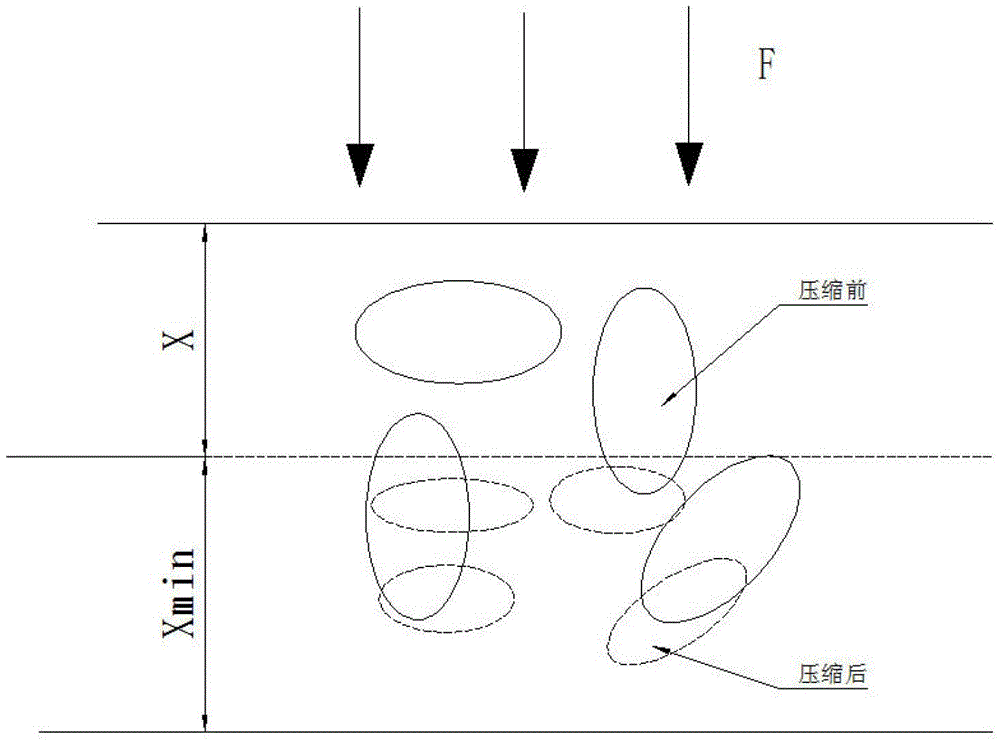

[0021] Such as figure 1 As shown, the preparation equipment of the composite separation membrane of the present invention has a material retracting rack 1 at the front and rear respectively, and a driving motor is installed on the front end retracting rack 1 for active unwinding of the unwinding material. The reaction frame 2 is welded by profiles, and transition guide rollers are installed on the frame to guide materials into the solution tank 3 . The solution tank 3 is welded with stainless steel plates, and a transition roller is installed in the tank, leaving a certain gap with the bottom, so that the material can be fully soaked and absorbed. A liquid volume control roller group 4 is installed between the two solution tanks 3 , the solution tank 3 and the liquid volume control roller group 4 are installed in the reaction frame 2 , and the liquid volume control roller group 4 is fixed on the reaction frame 2 . The liquid volume control roller group 4 includes a squeezing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com