Method for preparing heat barrier coating with column form crystal structure ceramic layer

A technology of columnar crystal structure and thermal barrier coating, applied in coating, metal material coating process, air transportation, etc., can solve problems such as coating peeling failure, volume expansion, etc., to improve thermal shock resistance and increase strain The effect of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

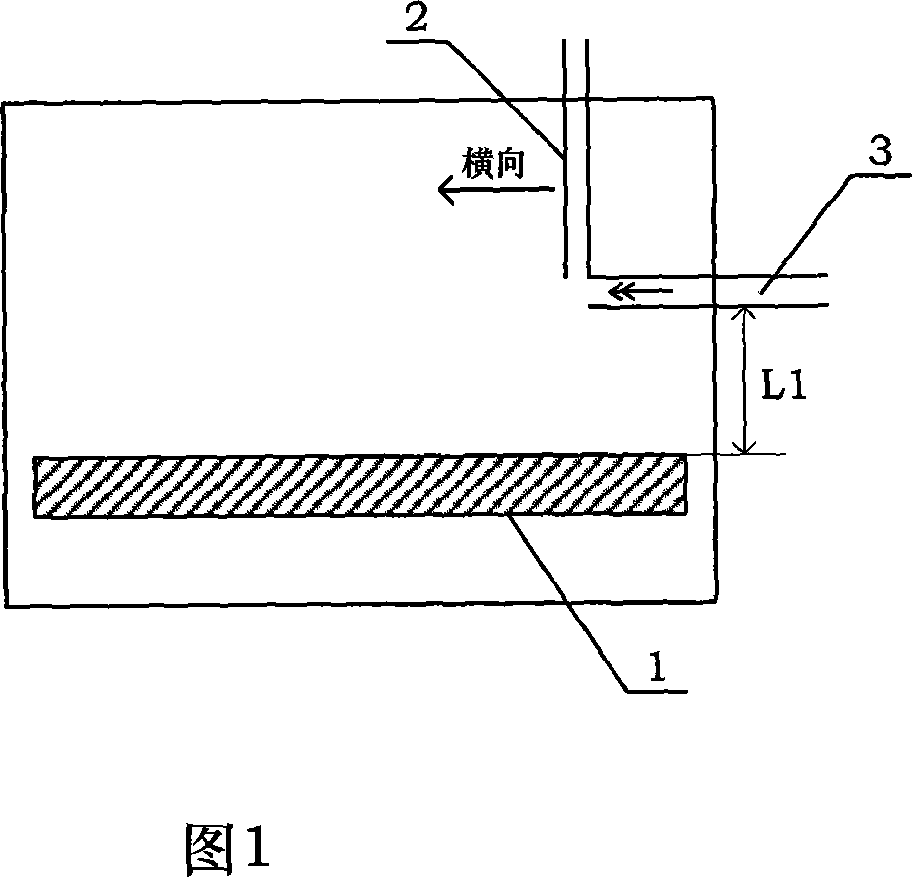

Method used

Image

Examples

Embodiment 1

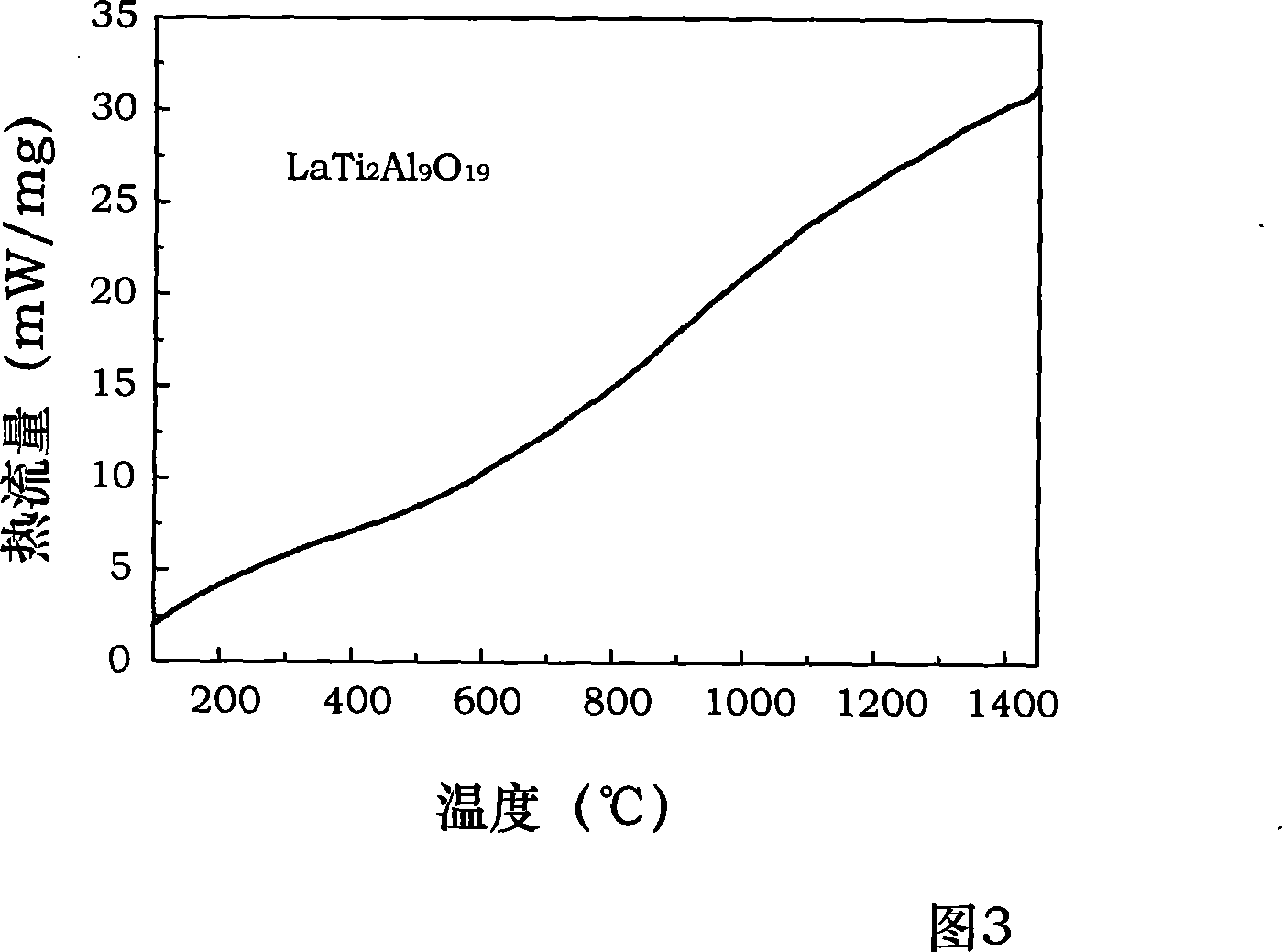

[0044] Powder materials required for preparing ceramic layer:

[0045] (A) Weigh the commercially available La according to the molar ratio of 1:4:9 2 o 3 Powder (99.99%, particle size 4μm, Youyan Rare Earth New Material Co., Ltd.) 407.5 grams, TiO 2 Powder 399.5g, Al 2 o 3 Powder (analytically pure, Beijing Lanyi Chemical Industry) 1147.05 grams, after 60 minutes of grinding by wet ball milling, a fine powder with a particle size of less than 1 micron was obtained, dried in a drying oven at 110°C and taken out to obtain a dry fine powder .

[0046] (B) Put the fine powder prepared in step (A) into a high-temperature furnace, set the heating rate of the furnace to 4°C min, adjust the reaction temperature to 1500°C, react for 24 hours and cool to room temperature with the furnace, take out the ball mill to Below 5 microns.

[0047] (C) Prepare the binder according to powder: binder=1:0.2 (mass ratio), the binder component is peach gum (the main component is organic sugars...

Embodiment 2

[0057] Example 2 is the same as Example 1 in preparing the powder material, the first step, and the second step process conditions, except for the third step.

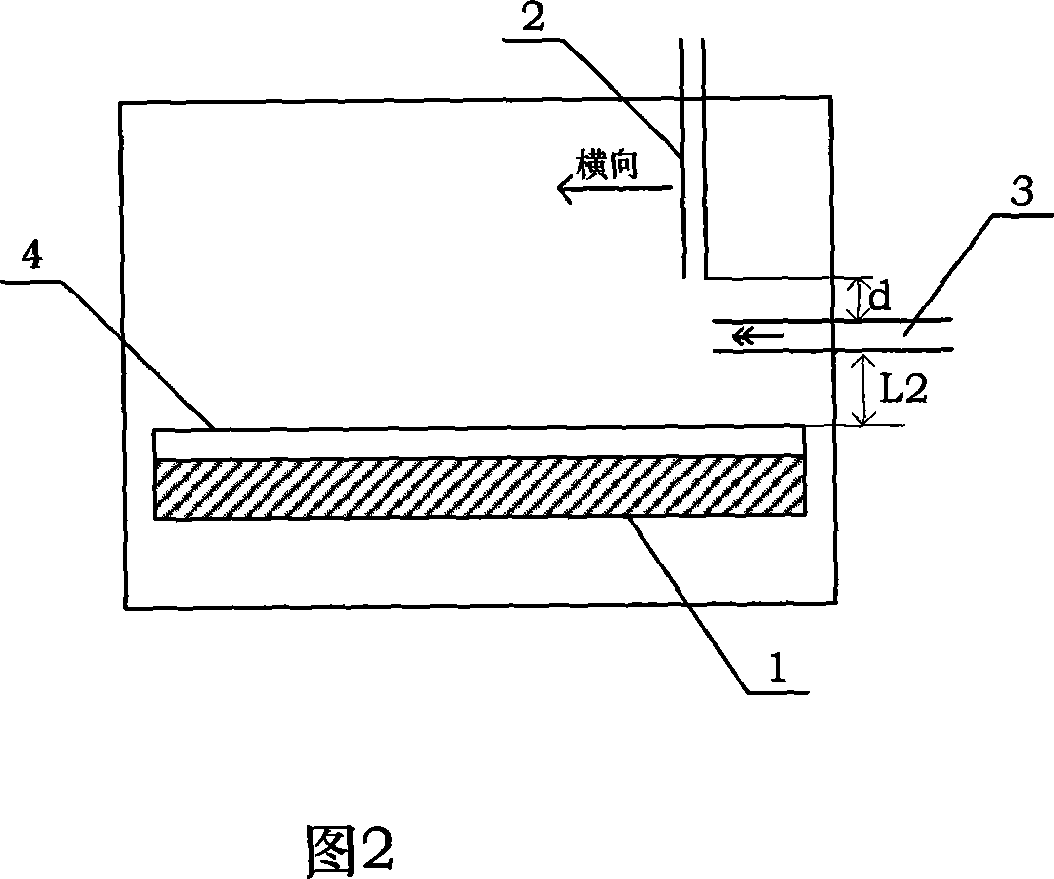

[0058] The third step: plasma spraying LaTi 2 al 9 o 19 ceramic layer

[0059] Take the granulated LaTix 2 al 9 o 19 The powder is 1100g, the spraying distance d is set to 30mm, the distance L2 is 70mm, the moving speed of the spray gun is 500mm / s, the plasma spraying voltage is 30V, the current is 800A, the powder feeding amount is 50g / min, and the substrate preheating temperature is 800°C , the thickness of the deposited ceramic layer is 1000 μm, and the deposition time is 20 minutes, that is, the preparation of the thermal barrier coating is completed.

[0060] In the thermal barrier coating prepared by the above process, the deposited ceramic layer has an electronic columnar crystal structure. The deposited coating is heated at 1300K°C (substrate temperature is 950°C to 1050°C) for 5 minutes, and then compre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com