Ultrahigh-characteristic-value three-phase flue gas foam for oil-gas field and preparation method thereof

A flue gas, characteristic value technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high cost of foam use and high cost of nano-particle application, achieve low cost, reduce industrial pollution sources, stability Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1. Ultra-high eigenvalue three-phase flue gas foam for oil and gas fields

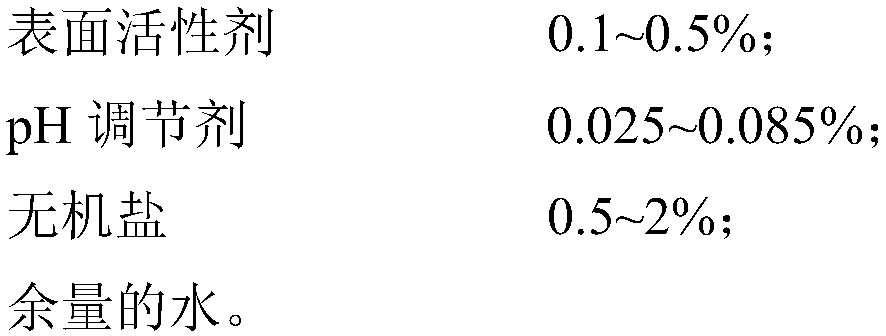

[0044] The raw materials are gas phase, liquid phase and solid phase, and the specific components are as follows:

[0045] The gas phase is the flue gas produced by the coal-fired power plant, which has undergone desulfurization, denitrification and deoxidation processes. The total fraction of nitrogen and carbon dioxide in the flue gas is ≈93%.

[0046] The maximum particle size of fly ash in the solid phase is 46 μm, the average particle size is 1.3 μm, SiO 2 Accounting for 63wt%, Al 6 Si 2 o 13 Accounting for 26wt%, Fe 2 o 3 The proportion is 6wt%, and the wetting angle of fly ash particles to distilled water is 57°; the average particle size of nano-silica in the solid phase is about 15nm, and the specific surface area is 160m 2 / g, the wetting angle of nano-silica particles to distilled water is 63°, and the mass ratio of fly ash to nano-silica particles is 8.5:1.

[0047] Th...

Embodiment 2

[0054] Example 2: Ultra-high eigenvalue three-phase flue gas foam for oil and gas fields

[0055] The raw materials are gas phase, liquid phase and solid phase, and the specific components are as follows:

[0056] The gas phase is the flue gas produced by the coal-fired power plant, which has undergone desulfurization, denitrification and deoxidation processes. The total fraction of nitrogen and carbon dioxide in the flue gas is ≈93%.

[0057] The maximum particle size of fly ash in the solid phase is 13 μm, the average particle size is 0.5 μm, SiO 2 Accounting for 71wt%, Al 6 Si 2 o 13 Accounting for 18wt%, Fe 2 o 3 The proportion is 3%, and the wetting angle of fly ash particles to distilled water is 54°; the average particle size of nano-silica in the solid phase is about 15nm, and the specific surface area is 160m 2 / g, the wetting angle of nano-silica particles to distilled water is 63°. - The mass ratio of fly ash to nano-silica particles is 8.5:1.

[0058] The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com