Stannum and carbon composite nano-fiber film negative-electrode material and preparation method thereof

A technology of carbon nanofibers and carbon-based nanofibers, which is applied in the field of new energy storage materials, can solve the problems such as literature reports and invention/practical patents of tin/carbon nanofiber composite film materials for lithium-ion battery negative electrodes, and achieve excellent results. Discharge performance and charge-discharge cycle stability, improved performance, simple configuration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

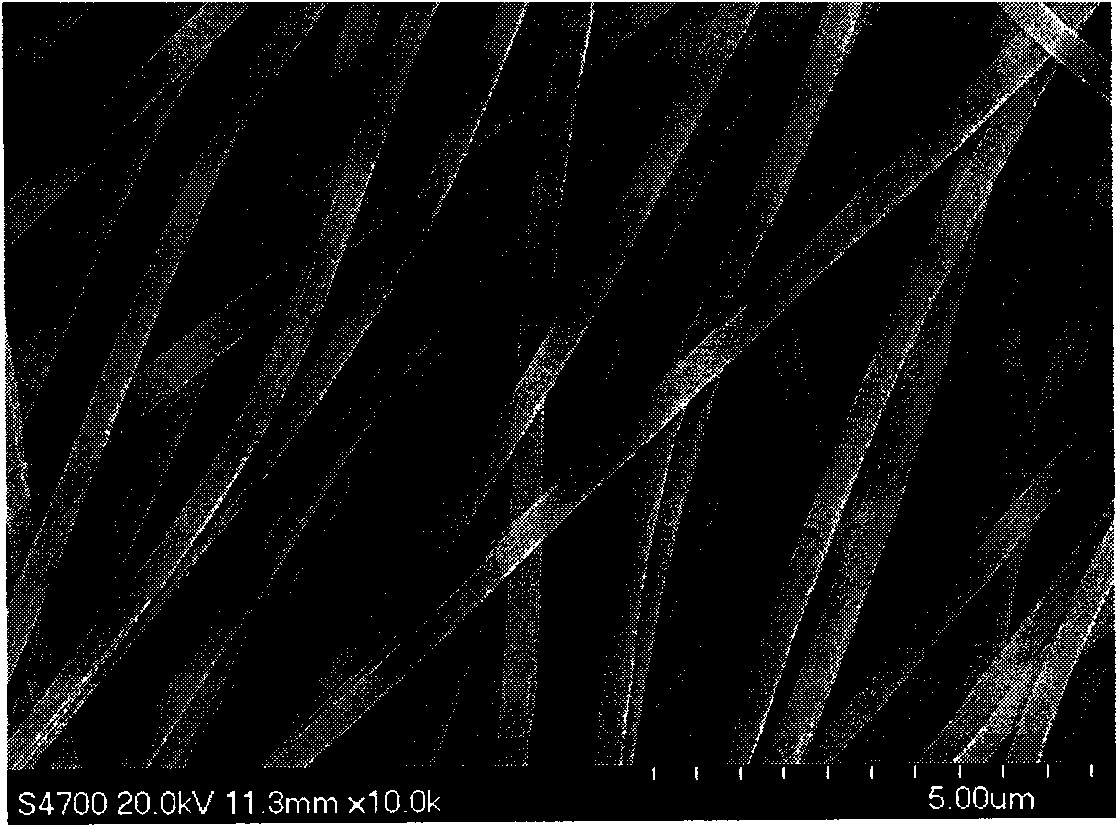

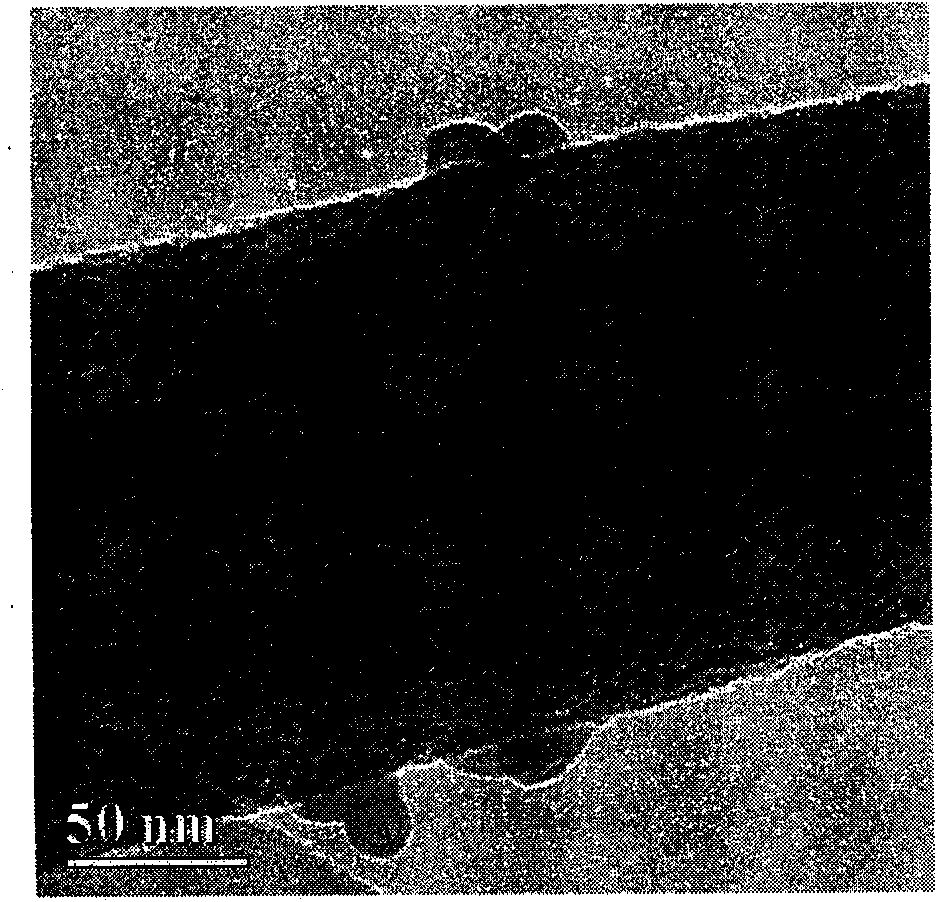

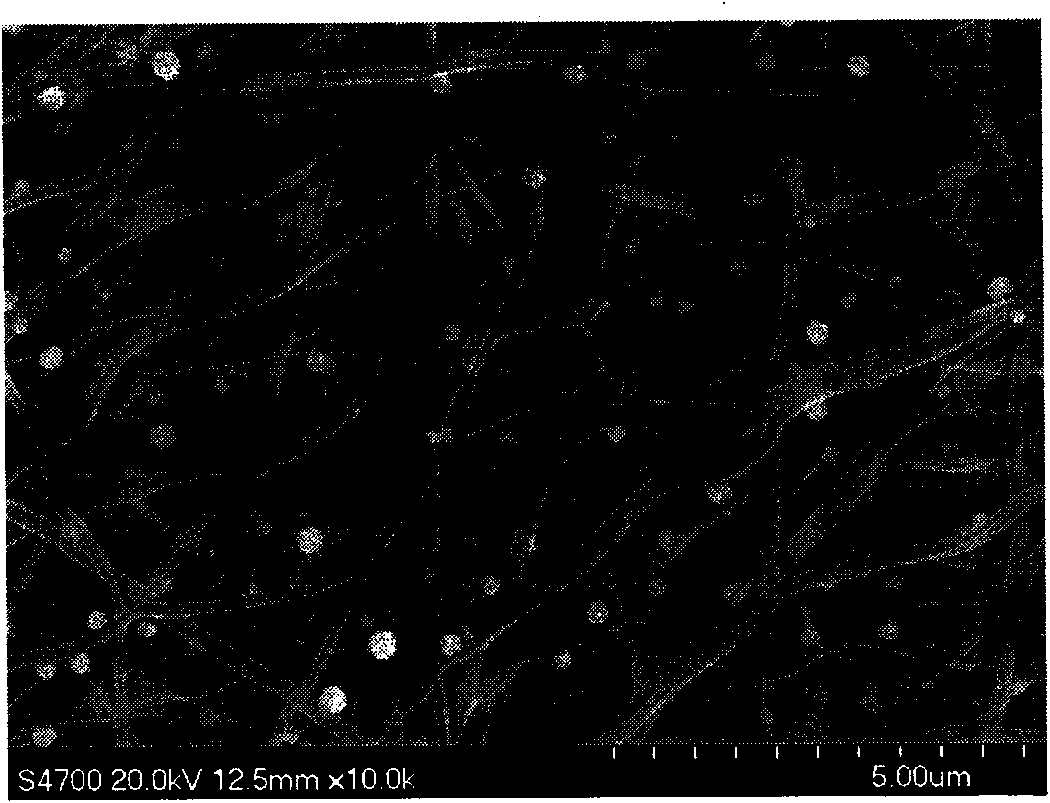

Embodiment 1

[0027] Add the homogeneous sol solution of 2.25ml of tin tetrachloride and 10mL of ethylene glycol into 20mL of polyacrylonitrile N-N dimethylformamide solution (concentration is 10wt%), and then stir under ultrasonic until a uniform solution is formed. solution for electrospinning. During the electrospinning process, a No. 12 injection needle (inner diameter of 1.1mm) was selected, the applied electrostatic voltage was 14kV, the flow rate of the spinning solution was 0.4mL / h, the receiving distance between the metal cylinder and the needle was 20cm, and the outer diameter of the cylinder was The line speed is 4m / s, and after 6 hours of spinning, a nanofiber mat / membrane with a certain thickness and partially parallel orientation is obtained. The resulting electrospun nanofiber mat / membrane was incubated at 120 °C for 4 h, and then pre-oxidized at 220 °C for 4 h. Finally, put the pre-oxidized fiber in a carbonization furnace and bake it under the protection of nitrogen at 850...

Embodiment 2

[0029] Add the homogeneous sol solution of 2.25ml tin tetrachloride and 10mL ethylene glycol into 20mL polyacrylonitrile N-N dimethylformamide solution (concentration is 11wt%), then stir under ultrasonic until forming A homogeneous solution is used for electrospinning. During the electrospinning process, a No. 12 injection needle (inner diameter of 1.1mm) was selected, the applied electrostatic voltage was 16kV, the flow rate of the spinning solution was 0.4mL / h, the receiving distance between the metal cylinder and the needle was 15cm, and the outer diameter of the cylinder was The line speed is 4m / s, and after 6 hours of spinning, a nanofiber mat / membrane with a certain thickness and partially parallel orientation is obtained. The resulting electrospun nanofiber mat / membrane was pre-oxidized at 270°C for 3 h. Finally, place the pre-oxidized fibers in a carbonization furnace and roast them for 1 hour at 1000°C under the protection of nitrogen, with a heating rate of 1°C / min...

Embodiment 3

[0031] Add the uniform sol solution of 1.75ml of tin tetrachloride and 15mL of anhydrous acetic acid into 20mL of polyvinylpyrrolidone in dimethylacetamide solution (concentration is 12wt%), then under ultrasonic stirring until a uniform solution for electrospinning. During the electrospinning process, a No. 12 injection needle (inner diameter of 1.1mm) was selected, the applied electrostatic voltage was 17kV, the flow rate of the spinning solution was 0.3mL / h, the receiving distance between the metal cylinder and the needle was 15cm, and the outer diameter of the cylinder was The line speed is 4m / s, after 6 hours of spinning, a certain thickness of partially parallel-oriented nanofiber mat / film is obtained, and then the fiber mat / film is placed in a carbonization furnace and roasted for 2 hours under the protection of argon at 700°C. The temperature is 10°C / min, and the tin / carbon nanofiber composite film material can be obtained by cooling at a cooling rate of 5°C / min, where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com