Environment-friendly impregnation system for fiber surface treatment, preparation method and impregnation method

A fiber surface and system technology, applied in the directions of surface pretreatment, bonding method, fiber treatment, fiber type, etc., can solve the problem of high price of dopamine, achieve simple preparation and fiber impregnation process, low price, and be beneficial to industrial production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

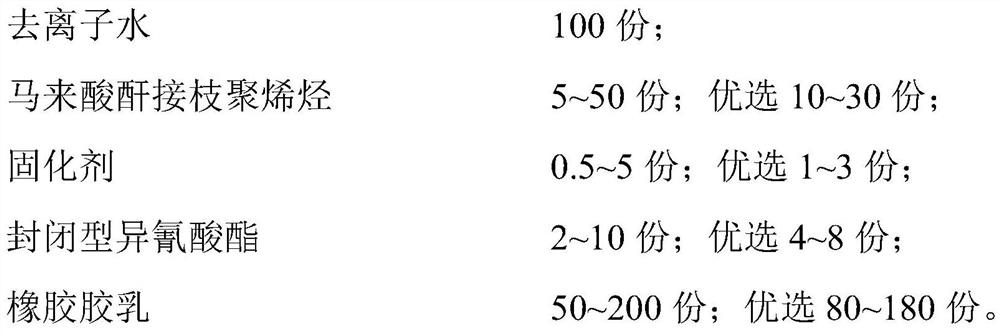

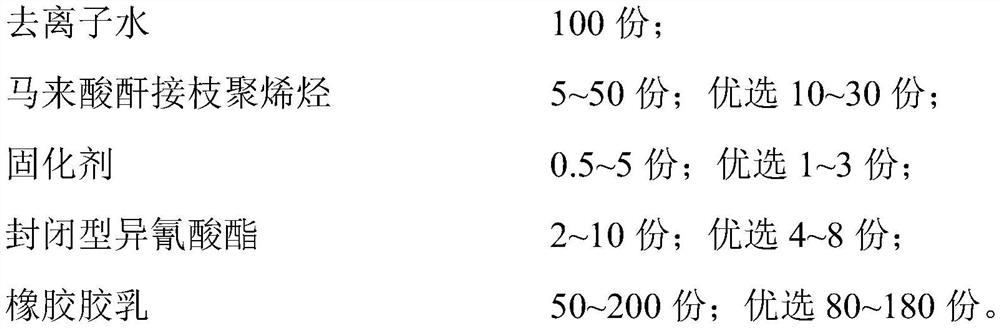

[0037] A kind of environment-friendly dipping system of fiber surface treatment, formula is as follows by weight: deionized water: 100 parts; 15 parts of polyolefins grafted by maleic anhydride (10 parts of maleic anhydride grafted polybutadiene, maleic anhydride 5 parts of grafted polyisoprene); 2 parts of curing agent (1 part of 2-methylimidazole, 1 part of 2-ethyl-4 methylimidazole); 6 parts of isocyanate (ε-caprolactam blocked diphenylmethane 6 parts of diisocyanate); 100 parts of rubber latex (50 parts of butylpyridine latex, 50 parts of butylpyridine latex).

[0038] Dipping liquid preparation process:

[0039] Add the amount of maleic anhydride grafted polyolefin and blocked isocyanate into deionized water, stir for 10 minutes to fully dissolve, then continue to add curing agent, and stir evenly at room temperature for 2 hours to obtain a uniform reaction solution. Then add latex, and continue to stir for 5 hours at normal temperature to obtain the dipping solution of ...

Embodiment 2

[0042] A kind of environment-friendly dipping system of fiber surface treatment, formula is as follows by weight: 100 parts of deionized water; 15 parts of polyolefin grafted with maleic anhydride (10 parts of maleic anhydride grafted polybutadiene, 5 parts of branched polyisoprene); 2 parts of curing agent (1 part of 2-methylimidazole, 1 part of 2-ethyl-4 methylimidazole); 5 parts of isocyanate (ε-caprolactam blocked diphenylmethane 3 parts of isocyanate, 2 parts of phenol-blocked isophorone diisocyanate); 50 parts of rubber latex (50 parts of butylpyridine latex).

[0043] Dipping solution preparation process: reference example 1.

[0044] One-bath immersion, drying temperature is 120°C, heat treatment temperature is 240°C; heat treatment time is 5min.

Embodiment 3

[0046] A kind of environment-friendly reinforced dipping system of fiber surface treatment, formula is as follows by weight: deionized water: 100 parts; 30 parts of polyolefins grafted by maleic anhydride (20 parts of grafted polybutadiene of maleic anhydride, maleic anhydride grafted polybutadiene 20 parts, 10 parts of acid anhydride grafted styrene-butadiene binary copolymer); 3 parts of curing agent (1 part of 2-methylimidazole, 2 parts of 4-dimethylaminopyridine); 8 parts of isocyanate (ε-caprolactam blocked di 4 parts of phenylmethane diisocyanate, 4 parts of butanone oxime-blocked trimethyl-1,6-hexamethylene diisocyanate); 150 parts of rubber latex (80 parts of butylpyridine latex, 40 parts of styrene-butadiene latex, styrene-butadiene latex 30 parts of pyridine latex).

[0047] Dipping solution preparation process: reference example 1.

[0048] One-bath immersion, drying temperature is 120°C, heat treatment temperature is 240°C; heat treatment time is 5min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com