Antimicrobial stock solution for nano-silver antibacterial paint, preparation method and application thereof

A nano-silver antibacterial and antibacterial agent technology, applied in the application field of nanotechnology, can solve problems such as restricting the promotion and use of inorganic antibacterial agents, antibacterial stability, and reducing antibacterial properties, and achieves increased grinding process, stable chemical properties, and wide application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

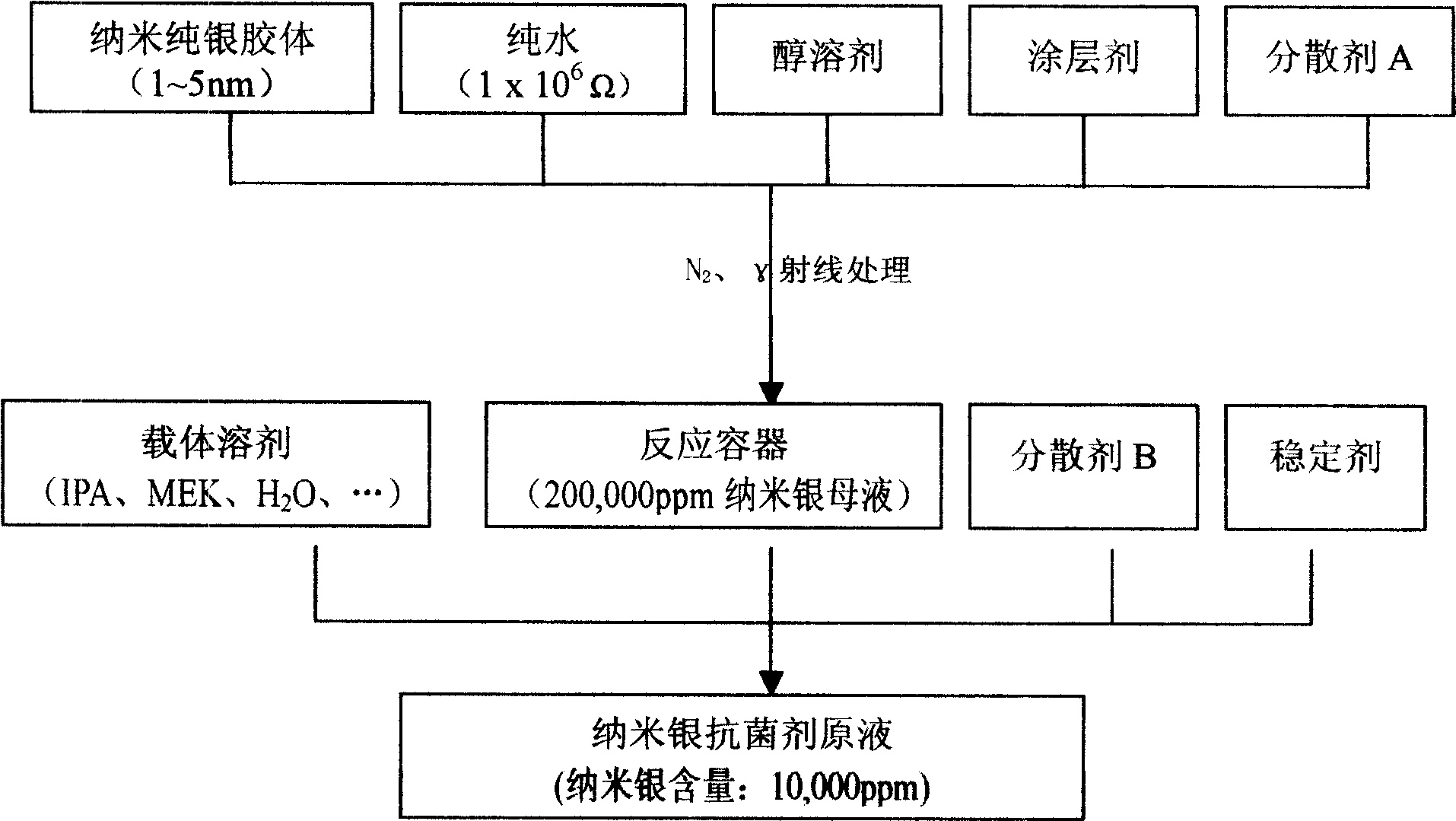

[0057] The preparation technology of nanometer silver antibacterial agent stoste, such as figure 1 shown.

[0058] The prepared nano-silver antibacterial agent stock solution must also ensure its own stability. After the nano-silver antibacterial agent stock solution prepared by the above-mentioned special polymer technology is continuously irradiated with UV light, it can still maintain a stable state from 1 day to 400 days. The results Such as Figure 5 shown.

[0059] The relationship between the amount of nano-silver added to the coating and the antibacterial effect.

[0060] Nano silver content: 30ppm Antibacterial technical indicators are as follows

[0061]

[0062] Nano silver content: 50ppm Antibacterial technical indicators are as follows:

[0063]

[0064] Nano silver content: 100ppm Antibacterial technical indicators are as follows:

[0065]

[0066] From the comparison and analysis of the data in the above table, according to the current antibacteria...

specific Embodiment approach 1

[0073] A nano-silver antibacterial coating antibacterial agent stock solution, its configuration is divided into two processes, first configure the nano-silver mother solution, its proportioning by weight is:

[0074] Nano Pure Silver Colloid 30g

[0075] Pure water 30g

[0076] Isopropanol 60g

[0077] Ethyl Acrylic Acid - Ethyl 20g

[0078] Polyethylene-carboxy polymer 1.5g

[0079] Preparation:

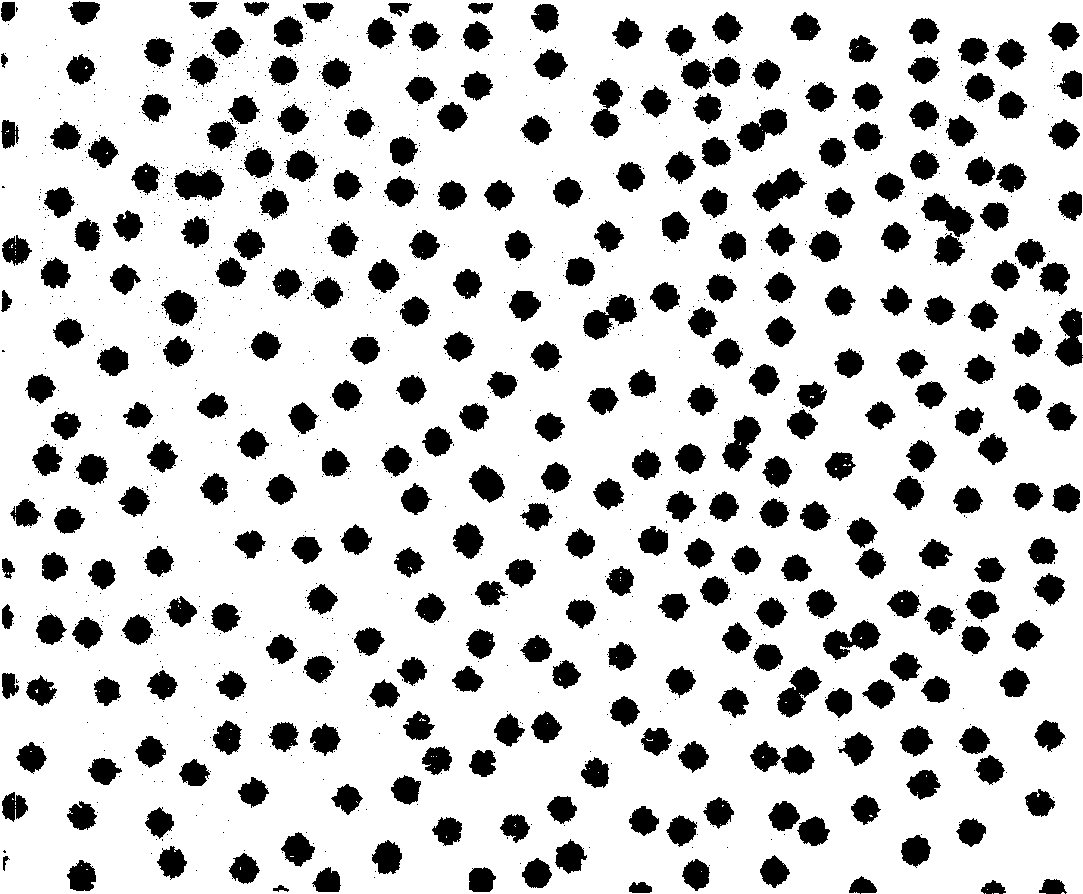

[0080] The first step is to prepare a silver colloid solution of particles with a diameter of about 1-5nm.

[0081] The second step is to prepare pure deionized water (resistance ≥ 1 million ohms).

[0082] In the third step, add the nano-silver colloid solution and purified water prepared in the first and second steps into a specially treated tempered glass tank, add dispersant and coating agent at the same time, and then fully stir to make the mixing reaction uniform.

[0083] In the fourth step, the reaction vessel was purged with nitrogen or argon for 12 hours, and tightl...

Embodiment 2

[0099] A nano-silver antibacterial coating antibacterial agent stock solution, its configuration is divided into two processes, first configure the nano-silver mother solution, its proportioning by weight is:

[0100] Nano Pure Silver Colloid 10g

[0101] Pure water 10g

[0102] Isopropanol 30g

[0103] Ethyl Acrylic Acid - Ethyl 10g

[0104] Polyethylene-carboxy polymer 0.5g

[0105] Preparation:

[0106]The first step is to prepare a silver colloid solution of particles with a diameter of about 1-5nm.

[0107] The second step is to prepare a mixed solution of pure deionized water and isopropanol (resistance ≥ 1 million ohms).

[0108] The third step is to add the nano-silver colloid solution prepared in the first and second steps and the mixed solution of water and isopropanol into a specially-treated tempered glass jar, add a dispersant and a coating agent at the same time, and then fully stir to make the Mix the reaction evenly.

[0109] In the fourth step, the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com