Ceramic filter core containing nanometer carbon crystal and nanometer diamond alkene blends

A nano-diamondene and nano-carbon crystal technology, applied in the field of ceramic filter cores, can solve the problems of difficulty in forming and processing and component equipment, high brittleness of inorganic materials, and high cost, and achieve stable physical and chemical properties, good adsorption properties, and reduced dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

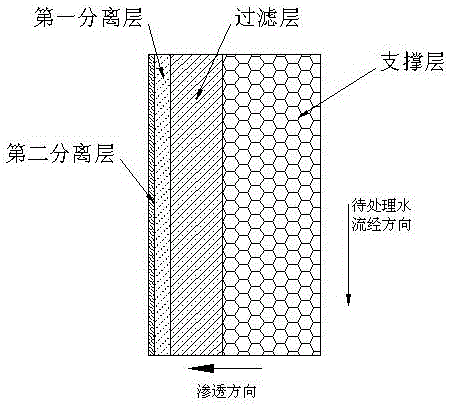

Image

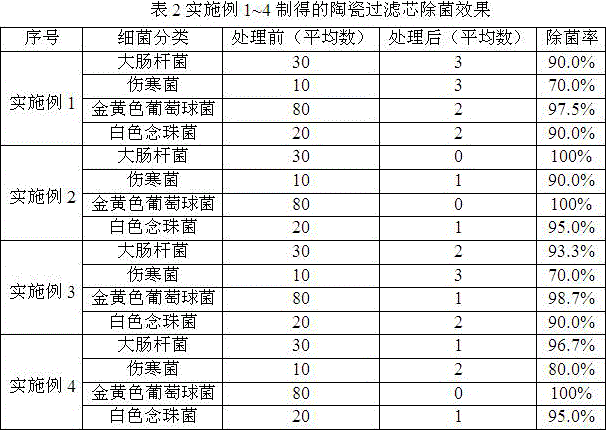

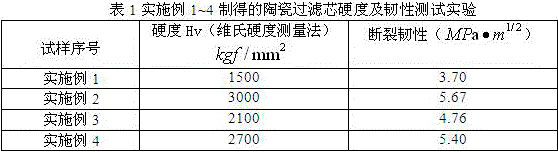

Examples

preparation example Construction

[0027] The preparation of nano-carbon crystals refers to the patent CN2015107503345. The prepared nano-carbon crystals have a spherical shape, the C content is 99-100%, and the lattice spacing is 0.21nm; the C atoms on the surface of the nano-carbon crystals and the inner diamond phase C atoms constitute a dimer structure of C atoms, and the two carbon atoms in the dimer structure of C atoms are distributed asymmetrically; the average particle size is R, and 0<R≤10nm. Nano-carbon crystals have the advantages of fine particles, high hardness, good wear resistance, extremely high specific surface area, excellent adsorption performance, and stable physical and chemical properties.

[0028] The preparation of nanodiamondene refers to the patent CN2015107492073. The prepared nanodiamondene has a lamellar single crystal structure, and the carbon atoms in the same sheet are sp 3 Orbital hybrid carbon bond connection, carbon atoms between layers are sp 2 Hybrid carbon bonds, C conten...

Embodiment 1

[0030] A kind of ceramic filter element that contains nano-carbon crystal and nano-diamantene blend is prepared by the following method, the steps are:

[0031] (1) Mix diatomite (made by mixing nano diatom earth and micron diatom earth at a mass ratio of 1:8), silicon carbide, nanocarbon crystals and water at a mass ratio of 1:0.8:0.1:0.5 1. Stirring for 0.5h to obtain a mud material, the mud material is matured and shaped to obtain a green body, and dried at 100°C to obtain a support layer;

[0032] (2) Mix nano-scale diatomite, silicon carbide, nano-carbon crystals and water according to the mass ratio of 1:0.5:0.2:0.6, and stir for 1 hour to prepare a slurry. After the aging treatment, the slurry is coated in the step ( 1) On the obtained support layer, dry at 100°C to form a filter layer on the surface of the support layer;

[0033] (3) Mix nano-carbon crystals, nano-diamondene, silver nitrate, nano-diatomaceous earth, silicon carbide, and water according to the mass rat...

Embodiment 2

[0039] A kind of ceramic filter element that contains nano-carbon crystal and nano-diamantene blend is prepared by the following method, the steps are:

[0040] (1) Diatomite (mixed by nano-diatomaceous earth and micron-diatomite in a mass ratio of 1:9), silicon carbide, nano-carbon crystals and water in a mass ratio of 1:1:0.3:0.9 1. Stirring for 3 hours to obtain a mud material, the mud material is matured and shaped to obtain a green body, and dried at 120°C to obtain a support layer;

[0041] (2) Mix nano-scale diatomite, silicon carbide, nano-carbon crystals and water according to the mass ratio of 1:0.8:0.5:1, and stir for 4 hours to prepare a slurry. After the aging treatment, the slurry is coated in the step ( 1) Dry the obtained support layer at 120°C to form a filter layer on the surface of the support layer;

[0042] (3) Mix nano-carbon crystals, nano-diamondene, silver nitrate, nano-diatomaceous earth, silicon carbide and water according to the mass ratio of 1:1:0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com