Waterborne resin antifogging coating special for films and antifogging film

An anti-fog coating and water-based resin technology, used in polyester coatings, coatings, other chemical processes, etc., can solve problems such as high price, affecting surface smoothness and uniformity, swelling and foaming, etc. Good film hardness and flexibility, durable anti-fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A special water-based resin anti-fog coating for film, the coating comprises a first composition and a second composition;

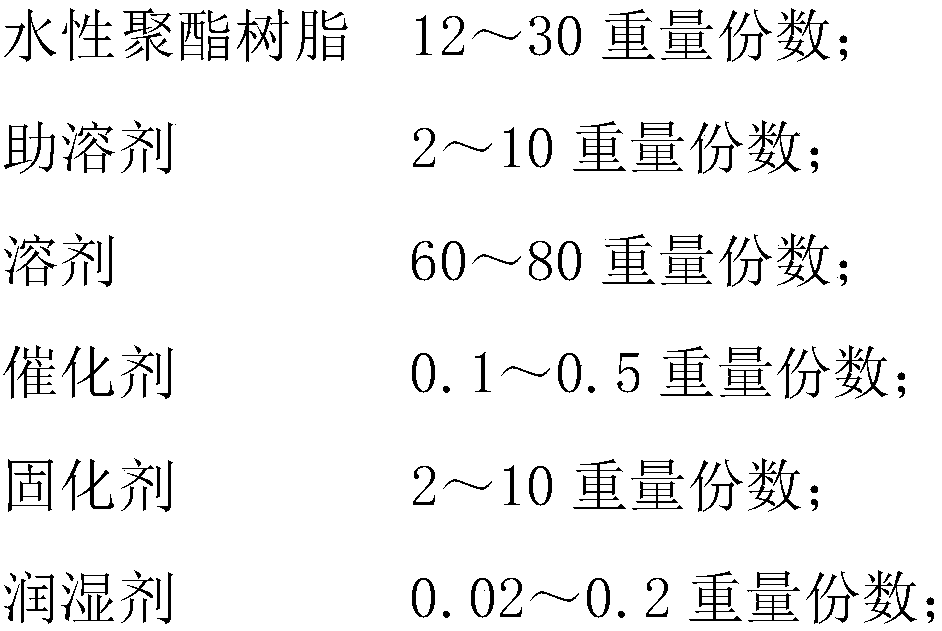

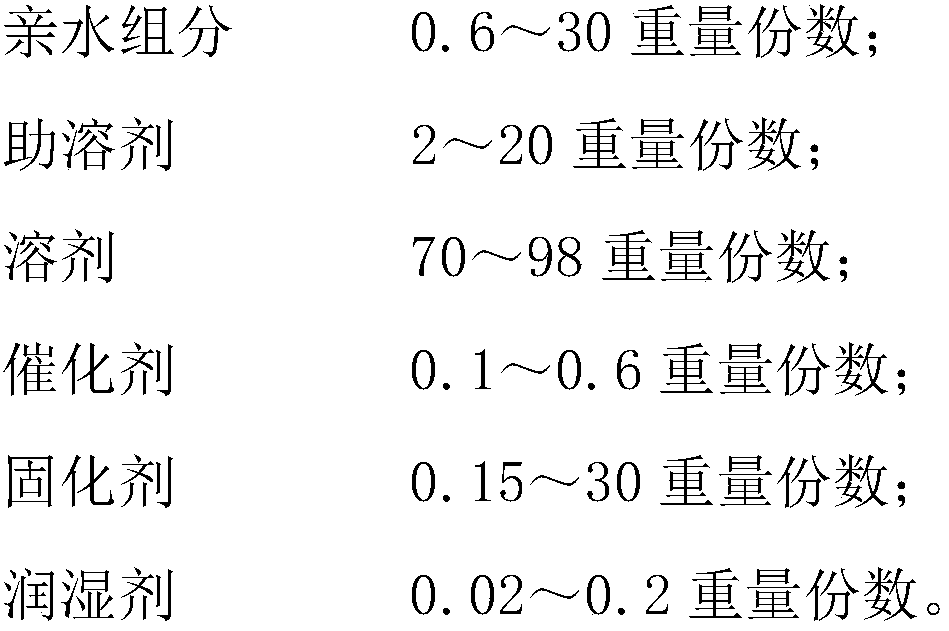

[0049] Wherein the first composition includes the following components by weight:

[0050]

[0051] The second composition includes the following components in parts by weight:

[0052]

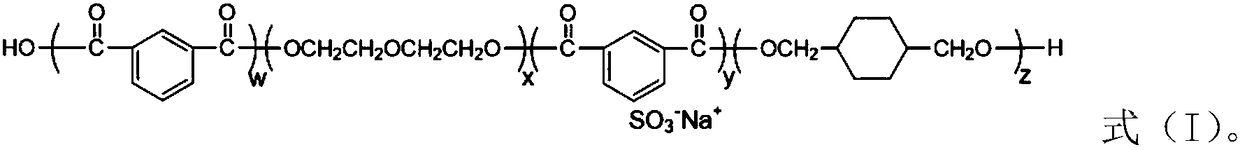

[0053] The number-average molecular weight of the water-based polyester resin is 7000; the cosolvent, solvent, catalyst, curing agent and wetting agent in the first composition are respectively the same as those in the second composition. The hydrophilic component is polyvinyl alcohol 1788 low viscosity type; the catalyst is toluene-4-sulfonic acid. The curing agent is methyl etherified amino resin. The wetting agent is polyether-modified polydimethylsiloxane. Described cosolvent is isopropanol; Described solvent is deionized water.

Embodiment 2

[0055] A special water-based resin anti-fog coating for film, the coating comprises a first composition and a second composition;

[0056] Wherein the first composition includes the following components by weight:

[0057]

[0058]

[0059] The second composition includes the following components in parts by weight:

[0060]

[0061] The number-average molecular weight of the water-based polyester resin is 7000; the cosolvent, solvent, catalyst, curing agent and wetting agent in the first composition are respectively the same as those in the second composition. The hydrophilic component is polyvinyl alcohol 1788 low viscosity type; the catalyst is toluene-4-sulfonic acid. The curing agent is methyl etherified amino resin. The wetting agent is polyether-modified polydimethylsiloxane. Described cosolvent is isopropanol; Described solvent is water.

Embodiment 3

[0063] A special water-based resin anti-fog coating for film, the coating comprises a first composition and a second composition;

[0064] Wherein the first composition includes the following components by weight:

[0065]

[0066] The second composition includes the following components in parts by weight:

[0067]

[0068]

[0069] The number-average molecular weight of the water-based polyester resin is 7000; the cosolvent, solvent, catalyst, curing agent and wetting agent in the first composition are respectively the same as those in the second composition. The hydrophilic component is polyvinyl alcohol 1788 low viscosity type; the catalyst is toluene-4-sulfonic acid. The curing agent is methyl etherified amino resin. The wetting agent is polyether-modified polydimethylsiloxane. Described cosolvent is isopropanol; Described solvent is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com