Method for forming insulating layer on overhead power transmission line

An overhead transmission line and insulating layer technology, applied in conductor/cable insulation, coating, epoxy coating, etc., can solve the problem of easy loosening of tapes, and achieve the effect of simple construction, good insulation and waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings. The following description is intended to explain the general concept of the present invention and should not be construed as a limitation.

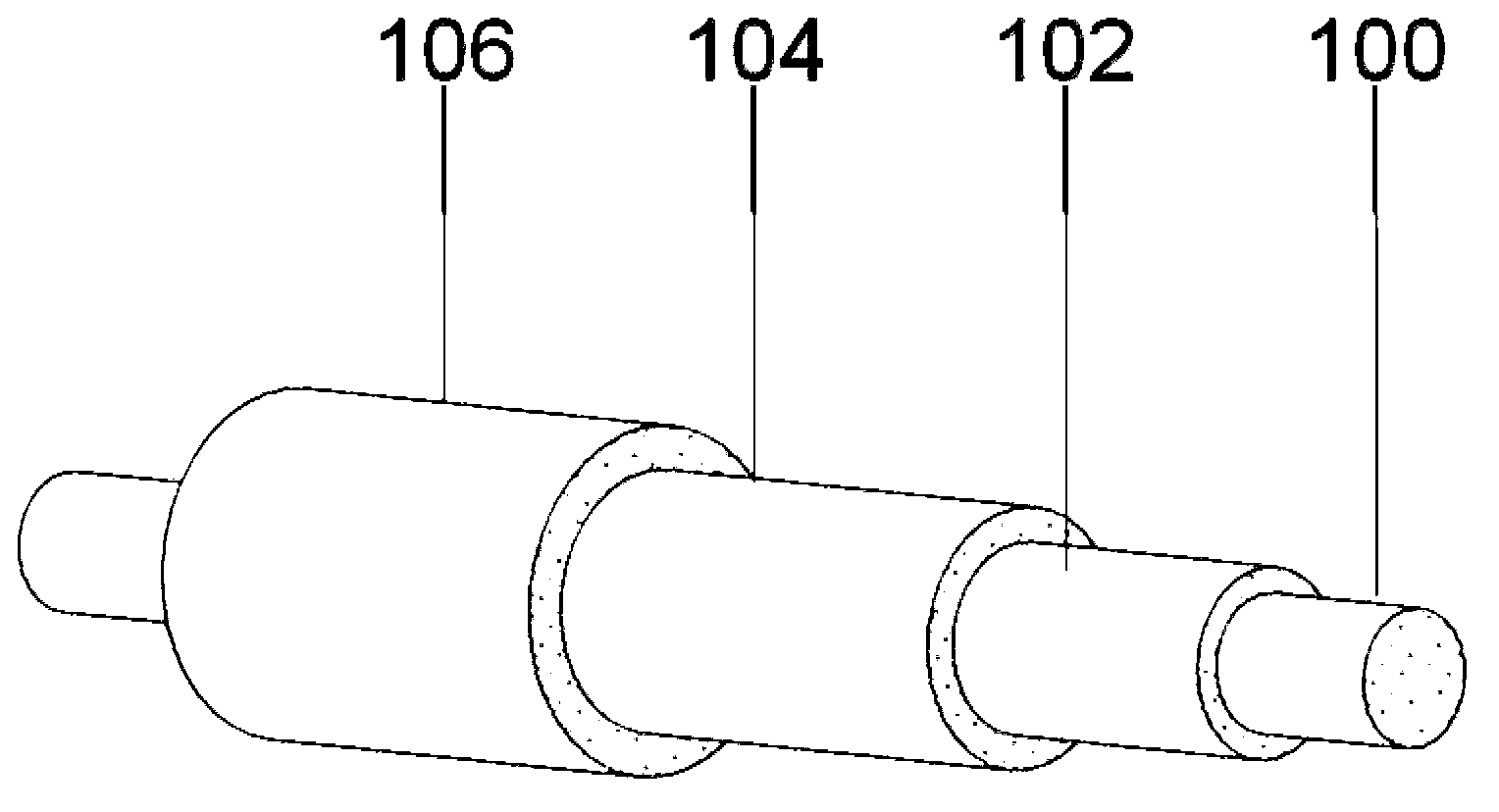

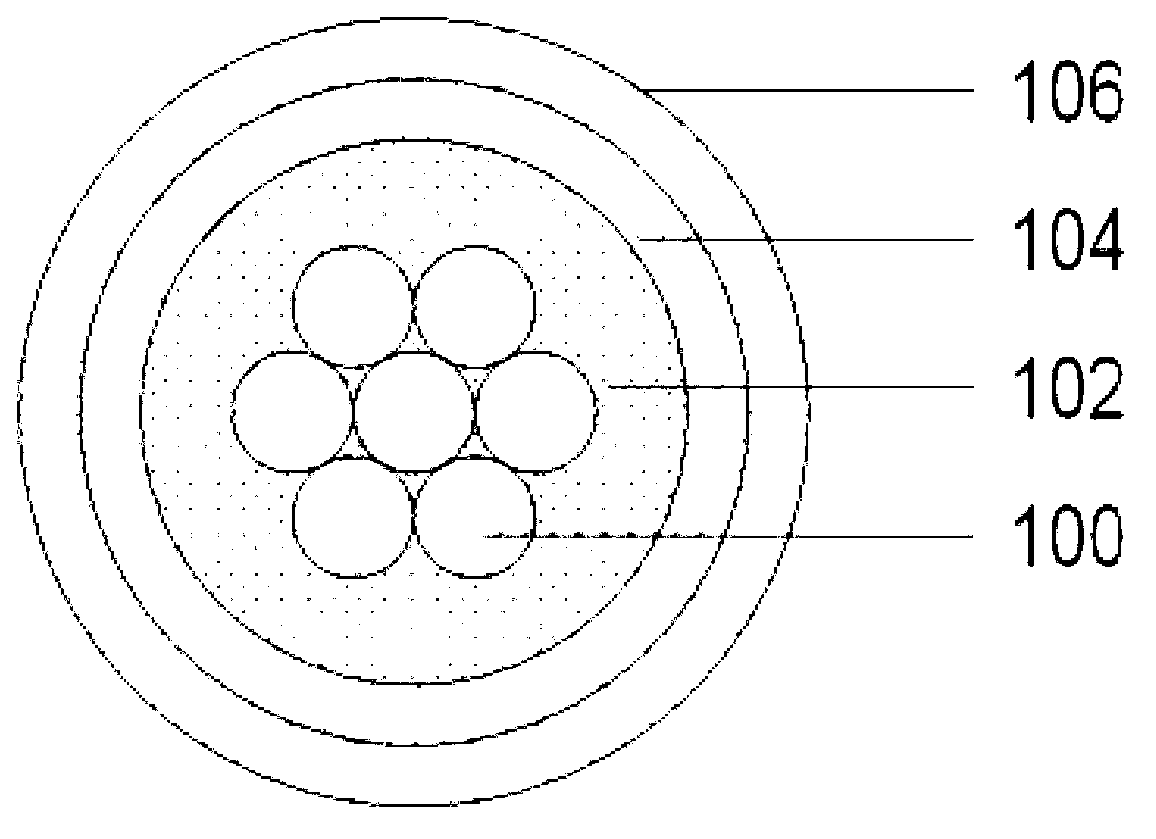

[0025] see figure 1 and figure 2 . According to the present invention, a method for forming an insulating layer on an overhead transmission line 100 comprises: painting a solvent-free coating (preferably a fast-curing solvent-free coating) on the transmission line to form a first coating 102; After 102 is semi-dry or dry, wind an electrical insulating tape on the first coating 102 to form a tape layer 104 ;

[0026] According to the present invention, the solvent-free coating used for the first coating 102 can be selected from one of epoxy, silicone or polyurethane organic solvent-free coatings. Applicable epoxy or polyurethane solvent-free coatings contain a bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com