Iron tailings mixing sand concrete

A technology of iron tailings ultra-fine sand and mixed sand, which is applied in the field of high-strength concrete and concrete preparation, can solve the problem that the utilization rate of iron tailings is less than 5%, and achieve improved pore size and distribution, good water retention, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

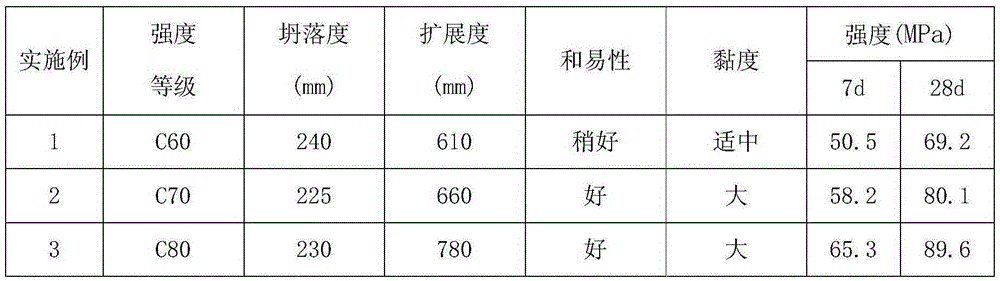

Examples

Embodiment Construction

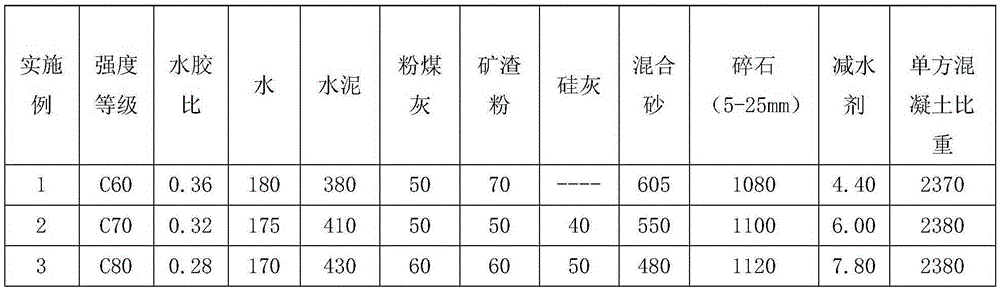

[0015] An iron tailings mixed sand concrete, the iron tailings mixed sand concrete is composed of 52.5 grade cement, iron tailings mixed sand, gravel, admixture, polycarboxylate superplasticizer and water, the iron tailings The mass percent of each component of ore-mixed sand concrete is: the 52.5 grade cement 16%-20%, the iron tailings mixed sand 22%-27%, the crushed stone 45%-48%, the blended 5.5% to 6.5% of the raw material, 7.3% to 8.1% of the water, and 0.2% to 0.3% of the polycarboxylate superplasticizer.

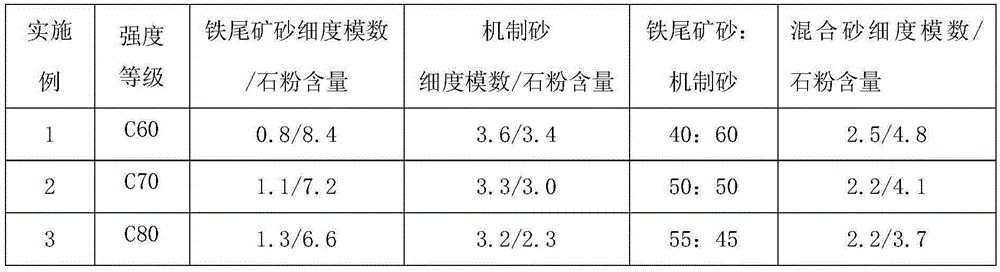

[0016] The fineness modulus of the iron tailings mixed sand is 2.5-2.8, and the mass percentage of stone powder in the iron tailings mixed sand is 2.0%-5.0%.

[0017] The iron tailings mixed sand is composed of iron tailings superfine sand and machine-made sand, the fineness modulus of the iron tailings superfine sand is 0.8-1.4, and the mass percentage of stone powder in the iron tailings superfine sand is The fineness modulus of the machine-made sand is 3.1-3.5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com