Cellulose grafted epoxy vegetable fat anionic polymeric surfactant and preparation method thereof

A technology of cellulose grafting and surfactants, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high equipment requirements and complicated processes, and achieve simple preparation processes, simple processes, and mild synthesis conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

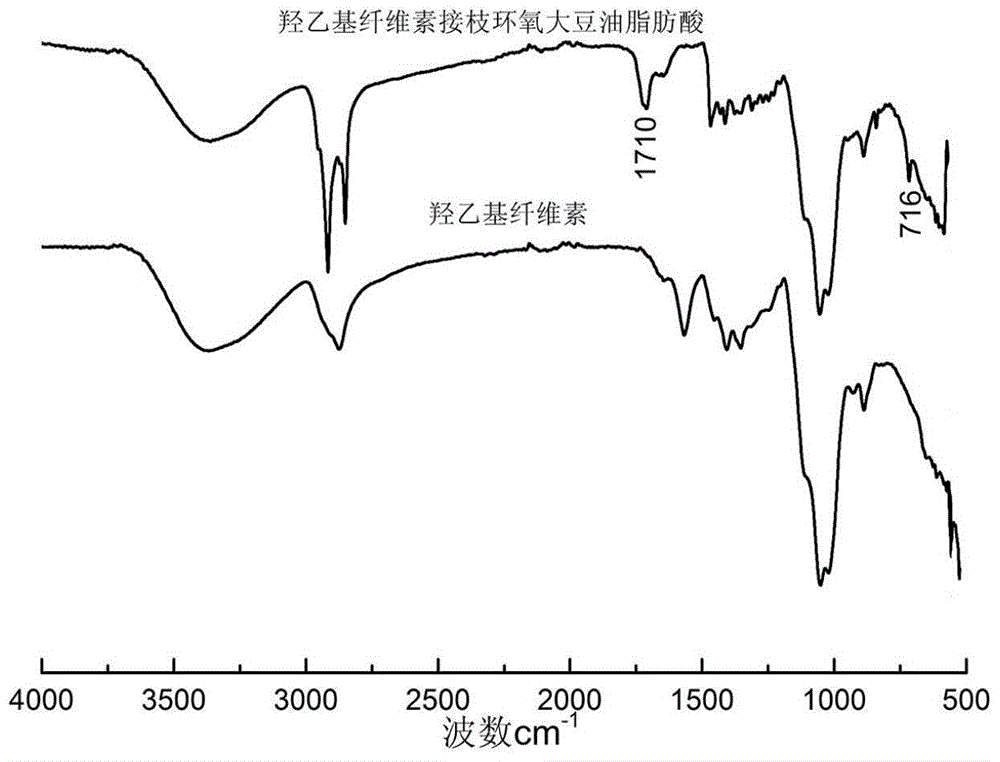

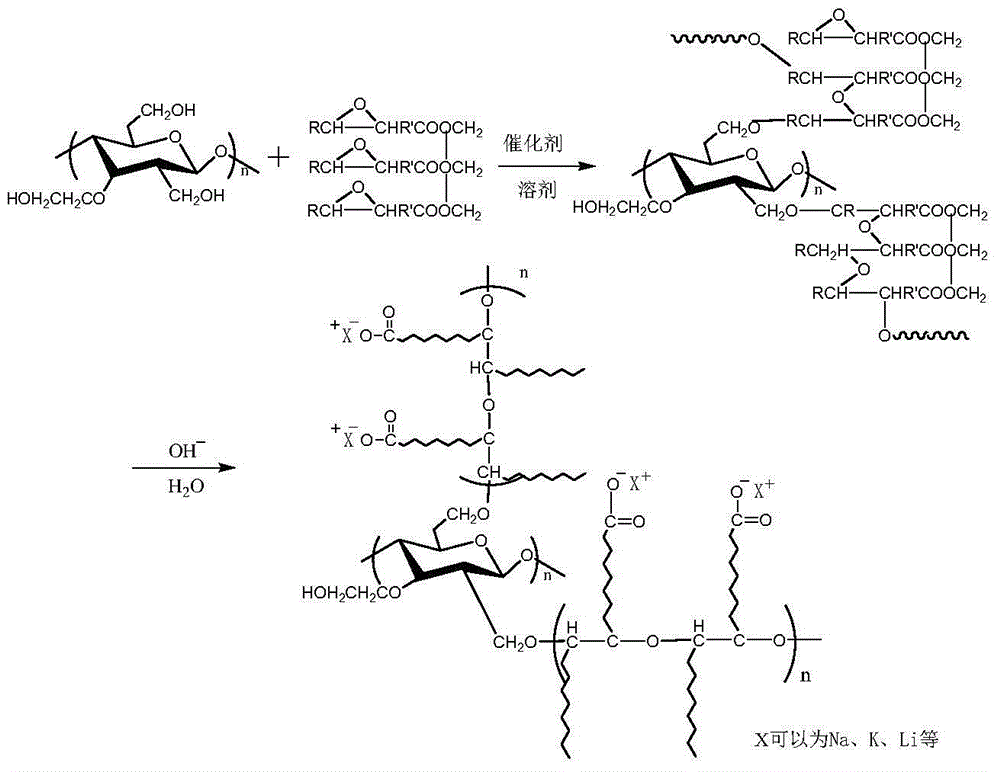

[0039] Weigh 3g of hydroxyethyl cellulose, fully dissolve it in 50mL of DMSO solvent and pour it into a 100mL three-neck flask. Add 10g of epoxidized soybean oil with an epoxy value of 6.3%, heat it to 40°C with magnetic stirring, and slowly drop a mixed solution of 0.02g of tin tetrachloride and 2mL of DMSO solvent through a constant pressure funnel for 5 minutes and react for 2 hours. After removing the DMSO solvent, the cellulose grafted epoxy soybean oil product was obtained. Weigh 1 g of the above product into a 100 mL three-neck flask, add 20 mL of 1 mol / L NaOH aqueous solution, and stir at a temperature of 90° C. to fully hydrolyze for 12 h. Cool down to room temperature, filter the reaction mixture, wash the solid product obtained after distilling the filtrate with ethyl acetate, and remove glycerin and unhydrolyzed oil. The solid obtained after washing is redispersed in distilled water and the pH value is adjusted to 4-6 with dilute hydrochloric acid solution, and th...

Embodiment 2

[0044] Weigh 2g of carboxymethyl cellulose, fully dissolve it in 40mL of DMF solvent and pour it into a 100mL three-neck flask. Add 10g of epoxy castor oil with an epoxy value of 4.3%, heat it to 50°C with magnetic stirring, and slowly add a mixture of 0.10g of zinc dichloride and 4mL of DMF solvent through a constant pressure funnel for 8 minutes and react for 1 hour. After removing the DMF solvent, the cellulose grafted epoxy castor oil product was obtained. Weigh 1 g of the above product into a 100 mL three-neck flask, add 30 mL of 0.5 mol / L NaOH aqueous solution, and stir at a temperature of 70° C. to fully hydrolyze for 22 h. Cool down to room temperature, filter the reaction mixture, wash the solid product obtained after distilling the filtrate with ethyl acetate, and remove glycerin and unhydrolyzed oil. The solid obtained after washing is redispersed in distilled water and the pH value is adjusted to 4-6 with dilute sulfuric acid solution, and the floating oil layer i...

Embodiment 3

[0047] Weigh 2g of hydroxypropyl cellulose, fully dissolve it in 45mL of DMSO solvent and pour it into a 100mL three-neck flask. Add 6g of epoxidized olive oil with an epoxy value of 3.3%, and heat to 60°C with magnetic stirring. Slowly add a mixed solution of 0.04g of trifluoroacetic acid and 2mL of DMSO solvent through a constant pressure funnel for 2 minutes and react for 1.5 hours. The cellulose-grafted epoxy olive oil product was obtained after removing the DMSO solvent. Weigh 1 g of the above product into a 100 mL three-neck flask, add 28 mL of 0.8 mol / L LiOH aqueous solution, and stir at a temperature of 80° C. to fully hydrolyze for 18 h. Cool down to room temperature, filter the reaction mixture, wash the solid product obtained after distilling the filtrate with ethyl acetate, and remove glycerin and unhydrolyzed oil. The solid obtained after washing is redispersed in distilled water and the pH value is adjusted to 4-6 with dilute phosphoric acid solution, and the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

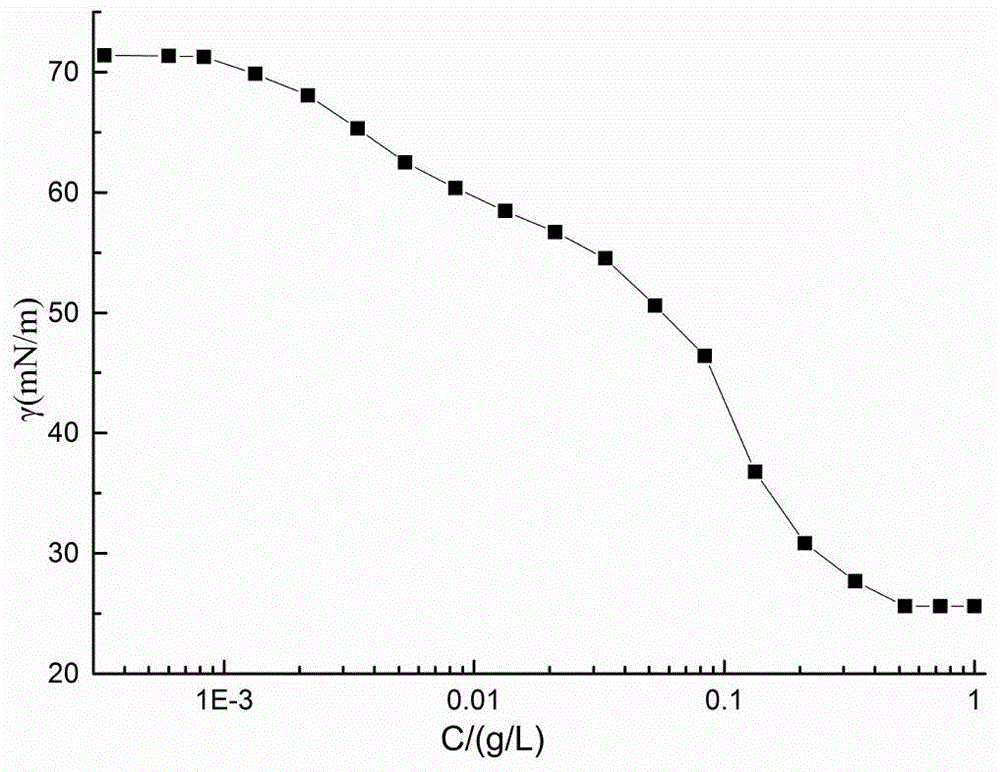

| Critical micelle concentration | aaaaa | aaaaa |

| Critical micelle concentration | aaaaa | aaaaa |

| Critical micelle concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com