Hollow steel pipe and concrete column filled with sea sand concrete and making method thereof

A technology for concrete-filled steel tubes and concrete columns, which is applied to columns, pillars, piers and other directions, can solve problems such as expansion, steel tube corrosion, and concrete brittleness, and achieve the effects of protecting the ecological environment, saving energy, and facilitating construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

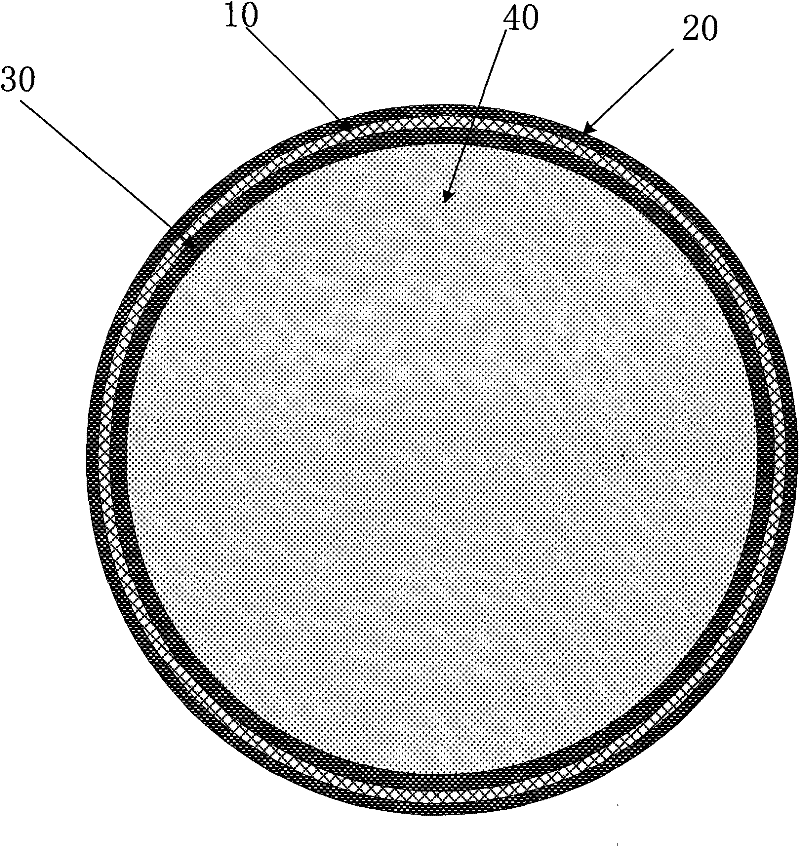

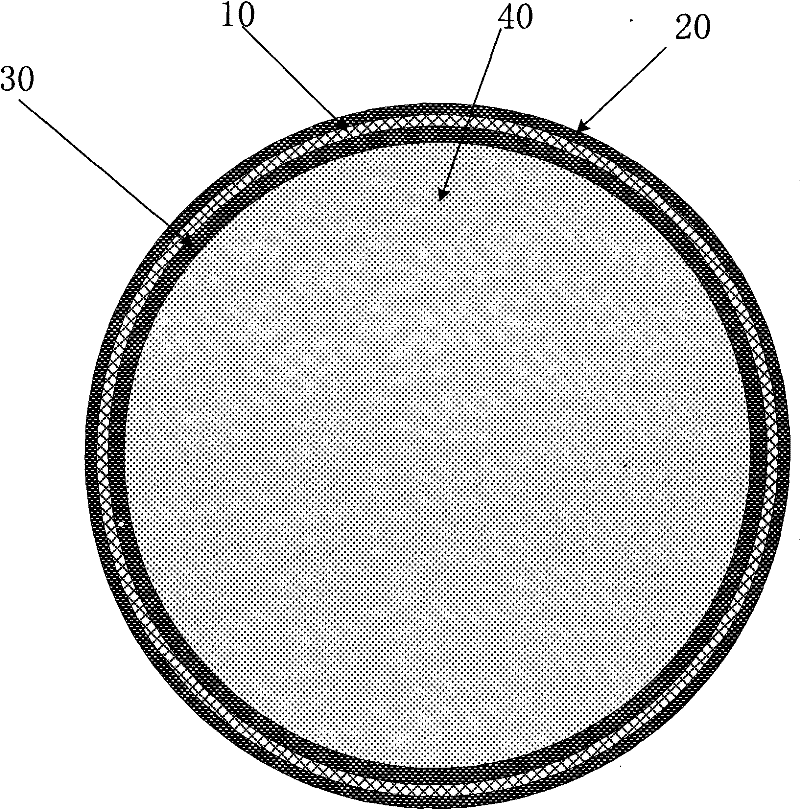

[0009] to combine figure 1 Specific embodiments of the present invention will be described in detail.

[0010] Depend on figure 1 It can be seen from the figure that the hollow concrete-filled steel pipe column with sea-sand concrete core includes a base 10 made of steel pipes, and an outer protective layer 20 of river sand concrete is poured on the outer wall of the base 10; The inner layer 30 of river sand concrete is cast with sea sand concrete 40 made of undesalted sea sand in the hollow area surrounded by the inner layer 30 . The hollow concrete-filled steel tubular columns of the element can be prefabricated in the factory, and then poured on site with internal sea-sand concrete. The thickness of the peripheral concrete can be controlled by the durability and fire protection requirements of the components. In general, the thickness of the protective layer of ordinary reinforced concrete (25-30mm) can meet the requirements. After 28 hours of curing, the internal concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com