Method for preparing nitrogen self-doped three-dimensional graphene from peels

A self-doping and graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as nitrogen self-doping three-dimensional graphene, etc., to meet sustainable development, reduce costs and prices. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

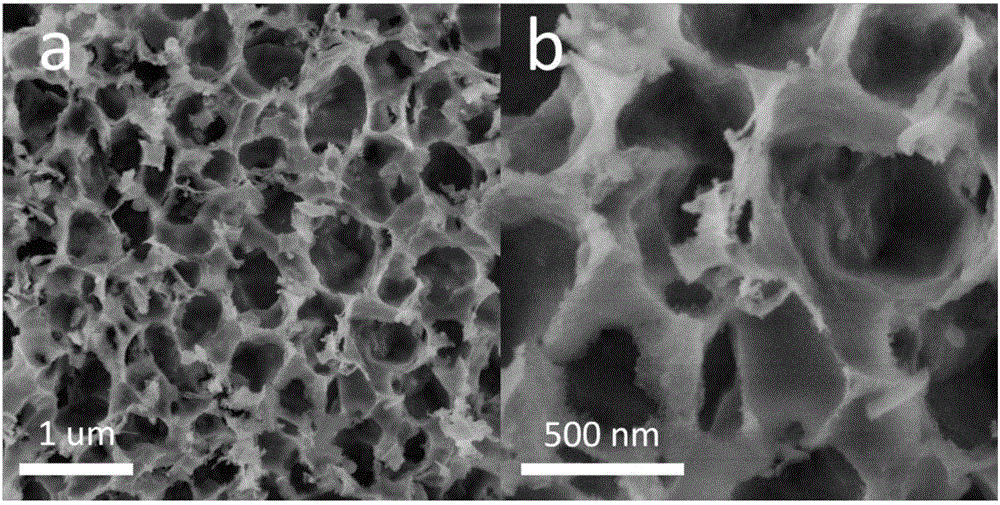

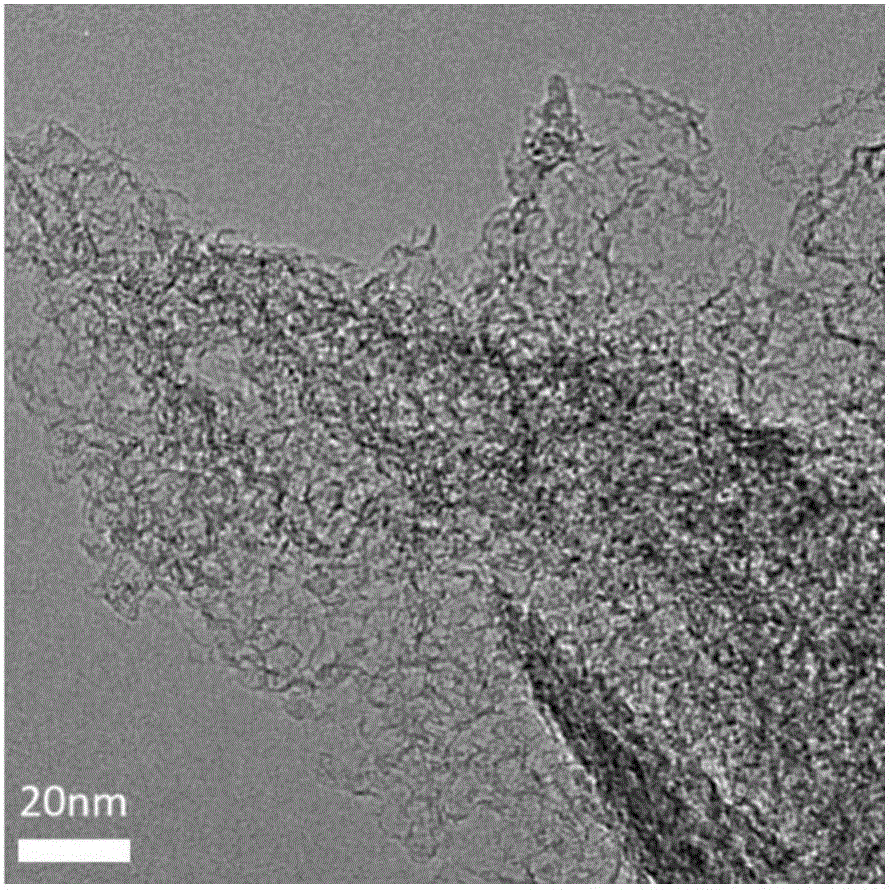

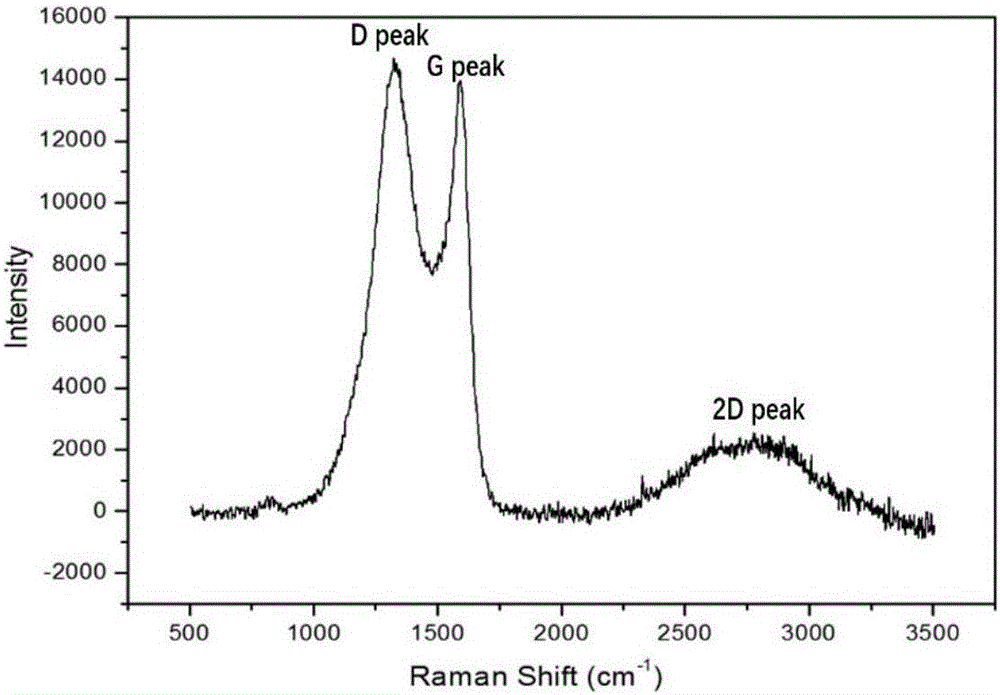

Image

Examples

Embodiment 1

[0041] 1) Wash the banana peel and cut into pieces, add water, and react with hydrothermal insulation at 180°C for 12 hours. Rinse the product repeatedly with water and filter to obtain a black gel-like carbide;

[0042] 2) Freeze-drying the gelatinous carbide in step 1) at -60°C and an absolute pressure of 20 Pa for 24 hours to obtain a preliminary carbonized product;

[0043] 3) Mix the preliminary carbonized product in step 2) with the KOH solid in a mass ratio of 1:2 and put it into a ball mill tank, add ethanol to the 3 / 4 position of the ball mill tank, and ball mill on a ball mill at a rate of 500 rpm for 5 hours;

[0044] 4) Dry the ball milled product in step 3) at 120°C until the ethanol is completely volatilized, and then under the protection of Ar gas at 5°C for min -1 The rate of heating up to 800 ℃ for 1h for high temperature activation;

[0045] 5) Put the product obtained in step 4) in 0.5mol.L -1 The unreacted activator and other impurities were removed by acid washing...

Embodiment 2

[0055] 1) Wash the orange peel and cut into pieces, add water, and react with hydrothermal insulation at 180°C for 18h. Rinse the product repeatedly with water and filter to obtain a black gel-like carbide;

[0056] 2) Freeze-dry the gelatinous carbide in step 1) at 0°C and an absolute pressure of 10 Pa for 48 hours to obtain a preliminary carbonized product;

[0057] 3) Combine the preliminary carbonized product in step 2) with K 2 CO 3 The solids are mixed according to the mass ratio of 1:1 and put into the ball milling tank, adding ethanol to the 3 / 4 position of the ball milling tank, and ball milling on the ball mill at a rate of 500 rpm for 5 hours;

[0058] 4) Dry the ball milled product in step 3) at 100°C until the ethanol is completely volatilized, and then under the protection of Ar gas at 5°C for min -1 The rate is increased to 600℃ for 1h for high temperature activation;

[0059] 5) Put the product obtained in step 4) in 0.1mol.L -1 The unreacted activator and other impuri...

Embodiment 3

[0065] 1) Wash the banana peel and cut into pieces, add water, and react under hydrothermal insulation at 190°C for 14 hours. Rinse the product repeatedly with water and filter to obtain a black gel-like carbide;

[0066] 2) Freeze-drying the gelatinous carbide in step 1) at -50°C and an absolute pressure of 50 Pa for 12 hours to obtain a preliminary carbonized product;

[0067] 3) Mix the preliminary carbonized product in step 2) with the NaOH solid in a mass ratio of 1:3 and put it into a ball mill tank, add ethanol to the 3 / 4 position of the ball mill tank, and ball mill on a ball mill at a rate of 500 rpm for 6 hours;

[0068] 4) Dry the ball milled product in step 3) at 120°C until the ethanol is completely volatilized, and then under the protection of Ar gas at 6°C for min -1 The rate of heating is increased to 700°C for 2h for high temperature activation;

[0069] 5) Put the product obtained in step 4) in 0.2mol.L -1 Pickling in sulfuric acid solution at 30°C for 10 hours to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com