Refuse-soil geopolymer solidifying material and preparation method thereof

A geopolymer and curing material technology, applied in the field of building materials, can solve the problems of high cost, achieve the effects of energy saving, ecological environment protection and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

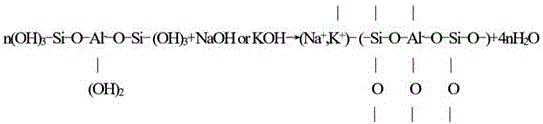

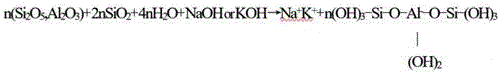

Method used

Image

Examples

preparation example Construction

[0042]A method for preparing a solidified material of slag geopolymer, comprising the following steps, step A: raw material pretreatment, the raw material pretreatment is to stir the raw material after drying and grinding, and the raw material includes fully weathered granite backfill One or more combinations of , silt, residual mud, sea mud, and sludge;

[0043] Step B: adding an alkaline activator, adding sodium hydroxide solution and sodium silicate solution to the raw materials obtained in step A according to the sequence while stirring; the sodium hydroxide solution and the sodium silicate solution The ratio of the sum of the mass to the raw material is 1:2.6-4.2; the ratio of the mass of the sodium silicate solution to the sodium hydroxide solution is 2.3-2.7:1; the modulus of the sodium silicate solution Be 2.0; The molar concentration of described sodium hydroxide solution is 14 mol / L;

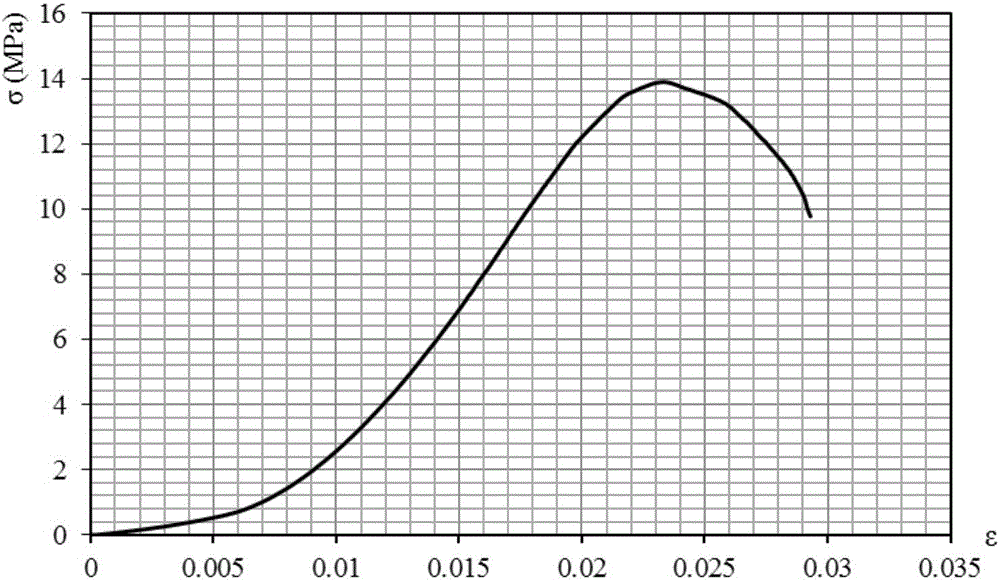

[0044] Step C: curing step; the curing step is to maintain the mixed system obtai...

specific Embodiment 1

[0050] muck NaOH solution Na 2 SiO 3 the solution

specific Embodiment 2

[0052] muck NaOH solution Na 2 SiO 3 the solution

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com