Method for preparing chitosan/crylic acid composite through initiating polymerization by using glow discharge electrolysis plasma

An electrolytic plasma and glow discharge technology, applied in the field of composite materials, can solve problems such as limited application and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Add 0.2 g CS, 0.07 g MBA and 35 mL of 2% acetic acid solution by mass percentage into a 250 mL three-necked flask, stir at 70°C to dissolve the mixture thoroughly, add 12 mL of AA, continue stirring for 10 min, turn on the power, and Perform glow discharge at 600 V, 43 mA for 5 min, and the current drops to 14 Am; stop the discharge, continue to stir in an oil bath at 75 °C for 3–4 h, then cool to room temperature to obtain a jelly-like gel; take out the product, cut it into pieces to about 2-5 mm, neutralize with NaOH to make the neutralization degree reach 90%; wash repeatedly with water and ethanol to remove unreacted raw materials, and finally dry in vacuum at 50°C to obtain CS / PAA hydrogel, crush and pass through 100 mesh Sieve, promptly obtain CS / AA composite material, yield 53%.

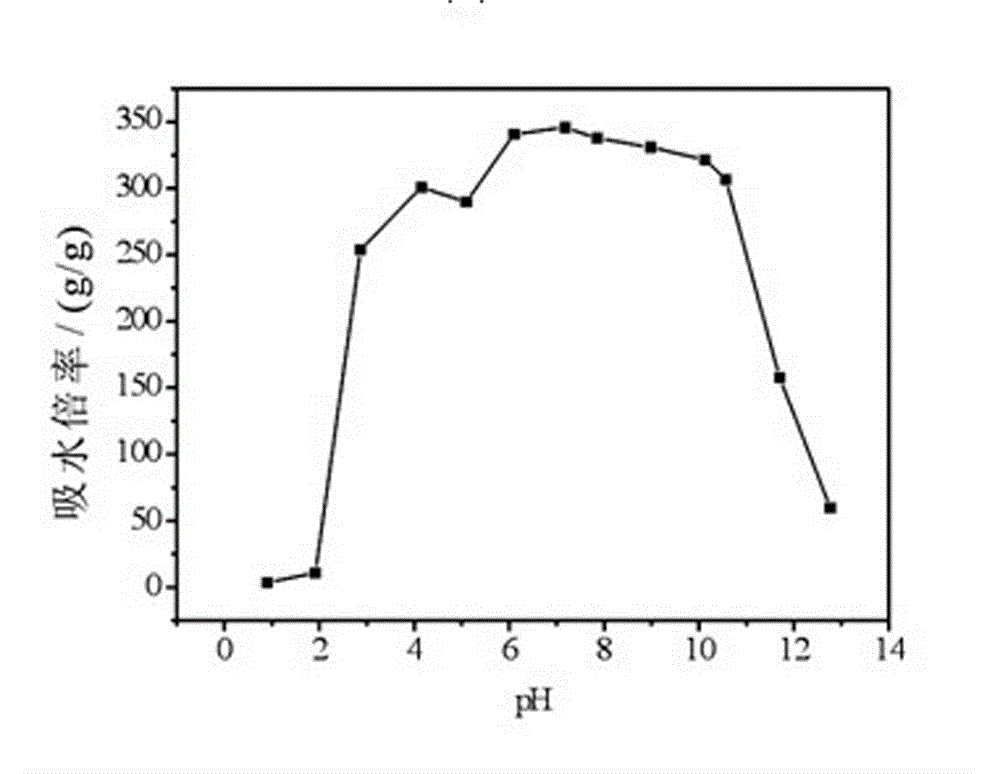

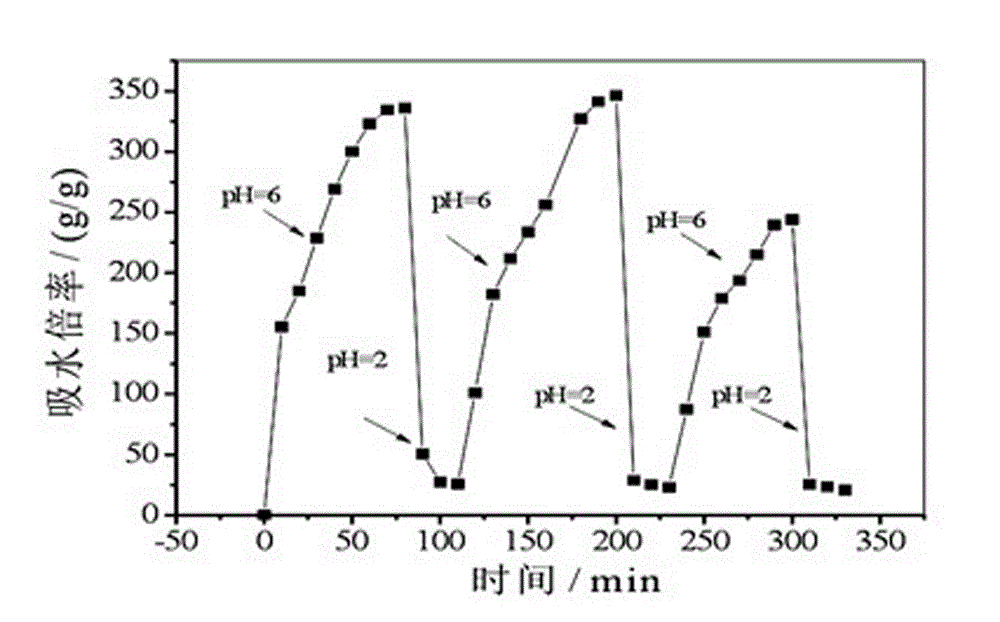

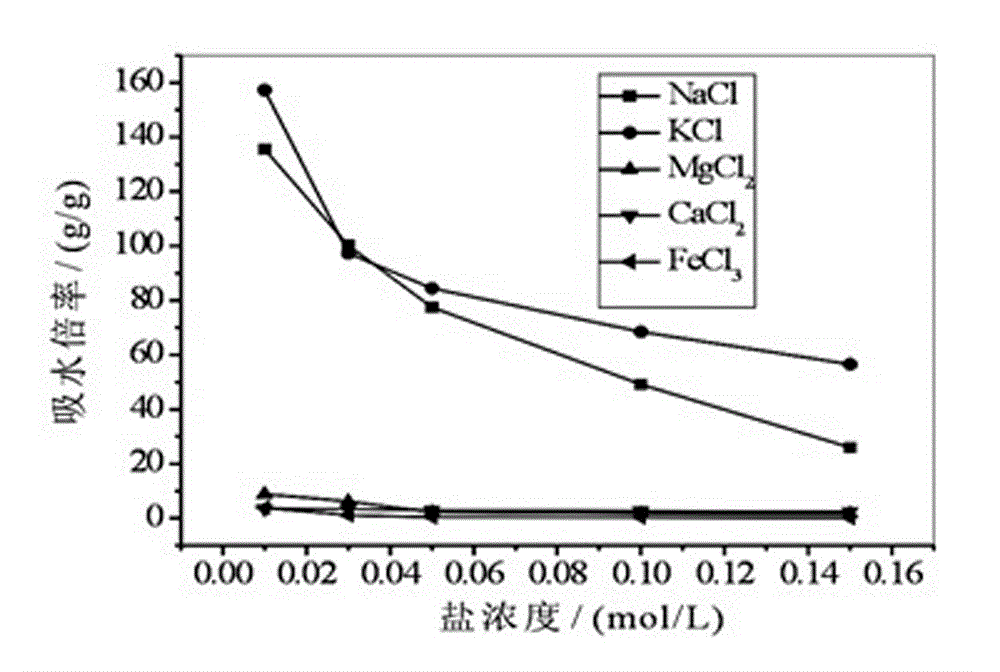

[0074] The performance indicators are as follows:

[0075] The amount of distilled water absorbed in 10 minutes is about 233 g / g, the maximum amount of distilled water absorbed is 250 ...

Embodiment 2

[0077] Add 0.3 g CS, 0.07 g MBA and 40 mL of 1% acetic acid by mass in a 250 mL three-necked flask, stir at about 75°C to dissolve the mixture completely, then add 9 mL of AA and continue stirring for 15 min, turn on the power supply, at a voltage of 600 V, Discharge at a current of 49 mA for 3 minutes and then the current drops to 11 mA, stop the discharge, continue to stir at 75 °C for 3~4 h (post-polymerization), cool to room temperature, and obtain a jelly-like gel; take out the product and cut it into a diameter of about 2~ 5 mm fragments, and then neutralized with 0.1 mol / L NaOH to make the neutralization degree reach 90%; the product was washed repeatedly with water and ethanol to remove unreacted raw materials, and vacuum-dried at 50°C to constant weight to obtain CS / PAA water After the gel was crushed through a 100-mesh sieve, a milky white composite material was obtained with a yield of 49%.

[0078] The performance indicators are as follows:

[0079] The amount of ...

Embodiment 3

[0081] Add 0.4 g CS, 0.14 g MBA and 35 mL of 5% acetic acid solution by mass to a 250 mL three-neck flask, stir at 80°C to dissolve the mixture thoroughly, add 10 mL of AA and continue stirring for 10 min, insert the two electrodes and turn on the power , glow discharge at 600 V, 49 mA for 4.5 min and the current dropped to 4 Am; stop the discharge, continue to stir in an oil bath at 75 ℃ for 3~4 h, cool to room temperature, take out the product, and cut it into pieces to about 2~5 mm, neutralized with NaOH to achieve a neutralization degree of 90%. Repeated washing with water and ethanol to remove unreacted raw materials, and finally vacuum drying at 50 °C to obtain CS / PAA hydrogel; pulverize and pass through a 100-mesh sieve to obtain CS / AA composite material with a yield of 51%.

[0082] The performance indicators are as follows:

[0083] The amount of distilled water absorbed in 10 minutes is about 245 g / g, and the amount of distilled water absorbed in 50 minutes is basic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com