Iron tailing super-fine sand concrete

A technology of iron tailings ultra-fine sand and concrete, which is applied in the field of concrete, can solve problems such as the difficulty in using construction sand directly, and achieve the effects of reducing concrete costs, reducing environmental damage, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1—4

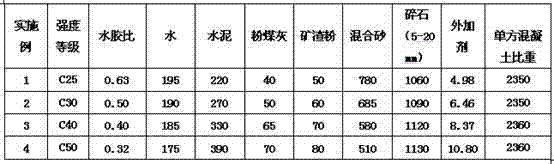

[0016] Table 1 lists the proportion of each component of the iron tailings ultra-fine sand concrete raw material of the present invention in the single concrete.

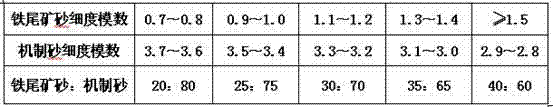

[0017] Table 2 lists the mixing mass ratio of iron tailings sand and machine-made sand in the mixed sand of the present invention.

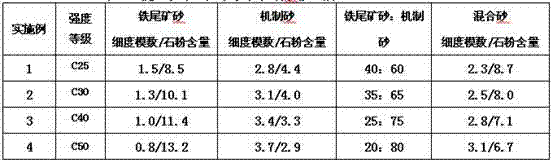

[0018] Table 3 lists the working performance and compressive strength of the iron ore tailings ultra-fine sand concrete of the present invention.

[0019] Table 1 The proportion of each component of the iron tailings ultra-fine sand concrete raw materials in the single concrete (kg / m 3 )

[0020]

[0021] Most domestic tailings have the characteristics of fineness, uneven particle size, and a certain amount of stone powder. The use of mixed sand can technically overcome the shortcomings of poor tailings sand gradation, especially the composite of iron ore tailings and machine-made sand. It can change the defect of fine tailings particle size and make the gradation rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com