Sea-sand concrete member and manufacturing method thereof

A technology of concrete and sea sand, which is applied to building structures, pier columns, buildings, etc., can solve the problems of high brittleness of concrete, corrosion and expansion of hollow steel pipes, and achieve the effects of energy saving, convenient construction, and ecological environment protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

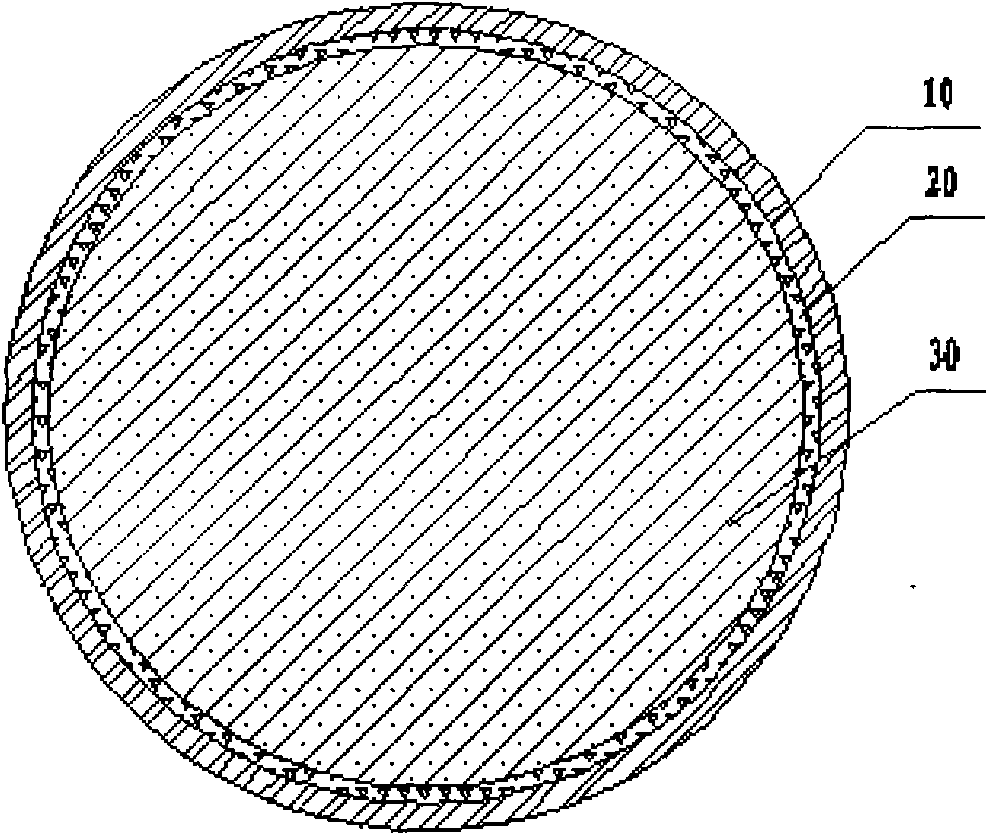

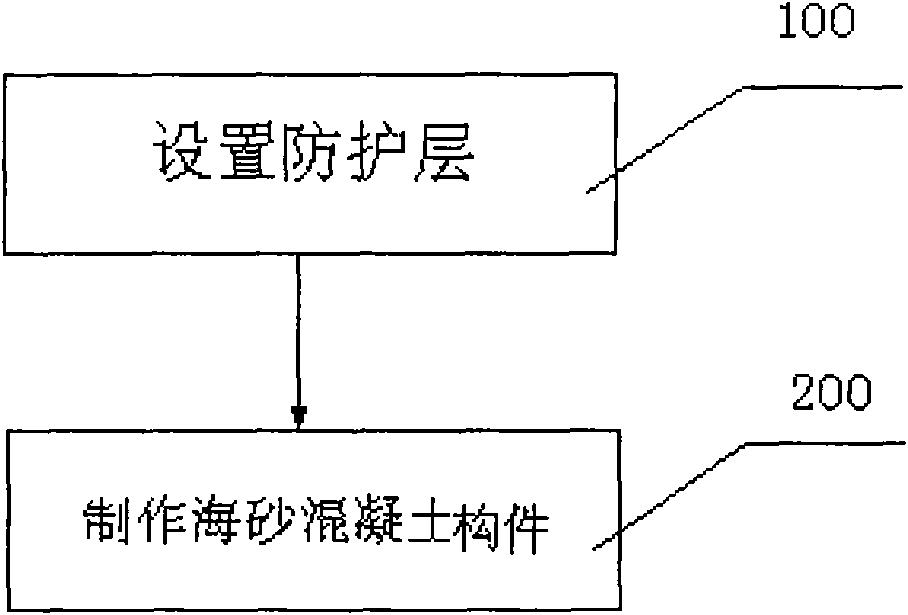

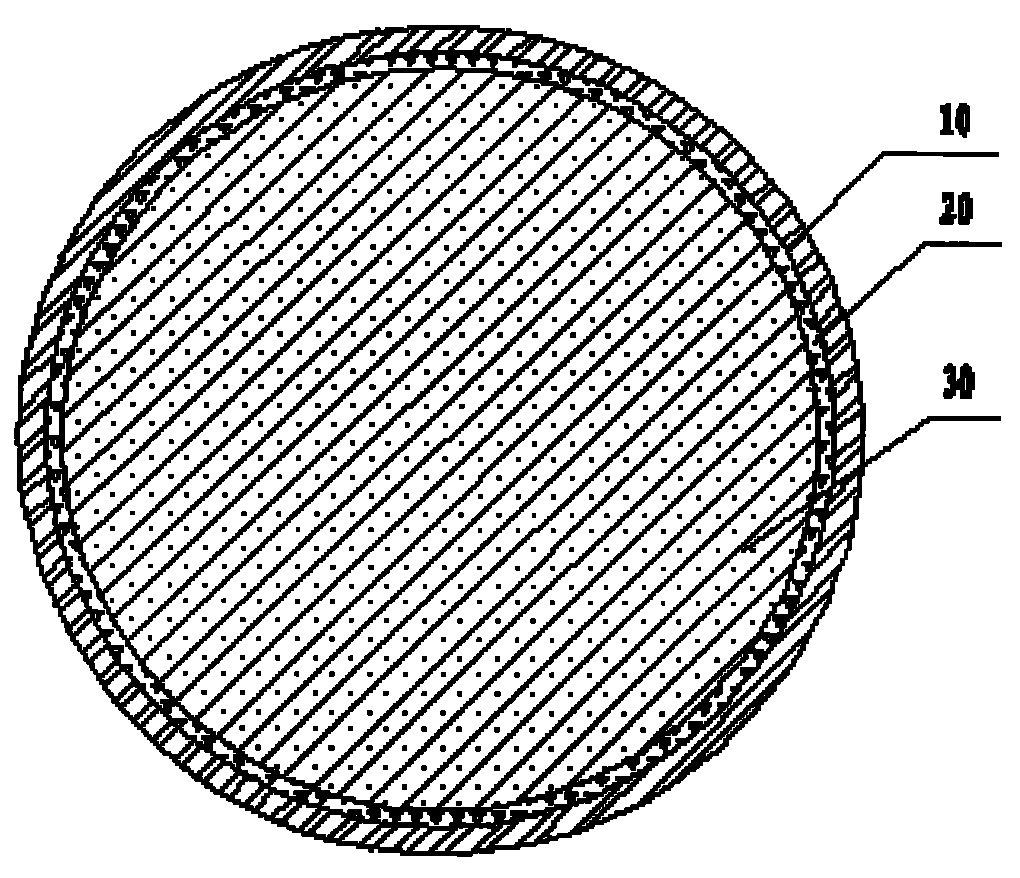

[0018] combine figure 1 Specific embodiments of the present invention will be described in detail.

[0019] Depend on figure 1 It can be seen from the figure that the sea-sand concrete member of this sea-sand concrete member includes a matrix 10 made of hollow steel pipes, a layer of protective layer 20 is arranged on the inner wall of the matrix 10, and undesalted sea sand is poured into the protective layer 20. sea sand concrete 30, the protective layer 20 is made of fiber reinforced composite plastic, and the protective layer 20 is used to prevent the sea sand concrete 30 made of undesalted sea sand from corroding the base 10. The protective layer provided in the hollow steel pipe of the component can be prefabricated in the factory, and then the internal sea sand concrete is poured on site. After 28 days of internal concrete curing, it can reach the design strength. Under the action of axial pressure, the outer hollow steel pipe provides a circumferential constraint o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com