Rereearth-iron base compound magnetic refrigeration material with large magnetic entropy change and preparation process thereof

A technology of magnetic refrigeration materials and compounds, applied in the direction of magnetic materials, magnetic objects, machine operation methods, etc., can solve the problems that it is difficult to meet the requirements of magnetic refrigeration materials, and achieve the effect of abundant raw materials, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

[0169] Figure 13The La(Fe 1-y co y ) 11.9 Si 1.1 (y=0.04, 0.06, 0.08) isothermal magnetic entropy change versus Gd. It can be seen from the figure that: near room temperature, the magnetic entropy change of this series of compounds is equal to or higher than twice that of Gd. Embodiment 5 prepares La (Fe 1-y m y ) 13-z Si z (M are Co, A1 and combination respectively, y=0.0676~0.194, z=0~1.17)

[0170] Compound La(Fe 1-y m y ) 13-z Si z (M are Co, Al and combination respectively, y=0.0676-0.194, z=0-1.17). Under the magnetic field change of 0-5 Tesla, the comparison between its isothermal magnetic entropy change and Gd is as follows: Figure 14 shown. It can be seen from the figure that through Al, Co and their combinations, we can easily adjust the Curie point from ~190K to above room temperature, and the magnetic entropy change is at or above twice that of Gd. Embodiment 6 prepares LaFe 13-z Si z C α (z=1.4, 1.5, α=0~0.6)

[0171] The direct smelting and ...

Embodiment 7

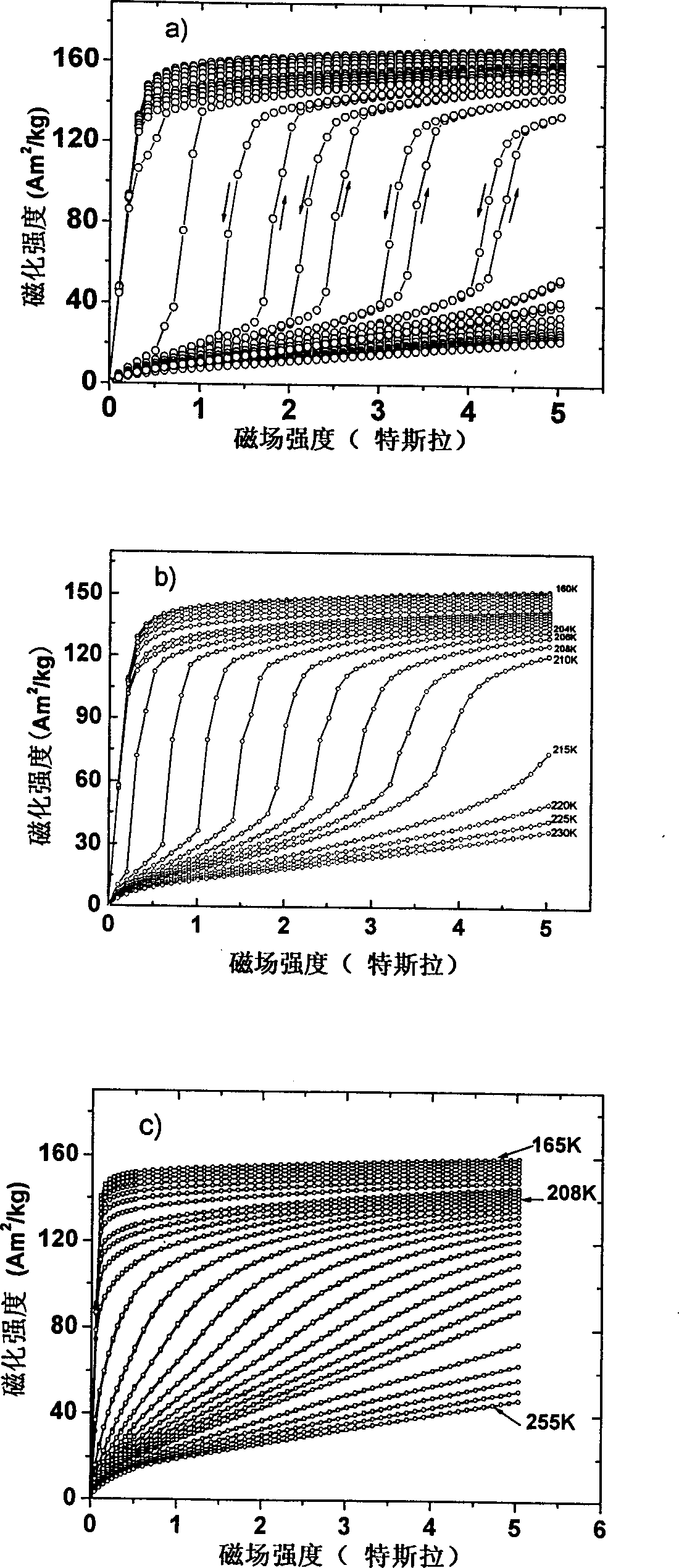

[0176] The LaFe prepared by embodiment 7 11.7 Si 1.3 N 0.2 The isothermal magnetization curve around the Curie temperature is as Figure 18 shown.

[0177] Figure 19 is based on Figure 18 Calculated LaFe 11.7 Si 1.3 N 0.2 Isothermal magnetic entropy change versus temperature curves for interstitial compounds. It can be seen from the figure: LaFe 11.7 Si 1.3 N 0.2 Interstitial compound Curie point T C Be 208K, compare the LaFe of embodiment 3 11.7 Si 1.3 Master Alloy (T C 190K) increased by 18K; under the change of external magnetic field from 0 to 5T, the magnetic entropy change at the Curie point reaches 15.47J / kg.K, which is 1.587 times that of Gd (9.75J / kg.K). Embodiment 8 prepares La 0.9 Gd 0.1 (Fe 0.7 co 0.2 mn 0.1 ) 11.6 Si 1.4 h 0.8

[0178] Prepare La by the technique of embodiment 2 0.9 Gd 0.1 (Fe 0.7 co 0.2 mn 0.1 ) 11.6 Si 1.4 h 0.8 Among them, H in the high pressure vessel 2 The pressure is 5.5 MPa, and the hydrogen absorption time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com