Rareearth-iron base compound magnetic refrigeration material with large magnetic entropy change and preparation process thereof

A technology of magnetic refrigeration materials and compounds, applied in the direction of magnetic materials, magnetic objects, machine operation methods, etc., can solve the problems that it is difficult to meet the requirements of magnetic refrigeration materials, and achieve the effect of abundant raw materials, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0142] Embodiment 1 prepares LaFe 13-z Si z (z=1.2, 1.4, 1.6)

[0143] Preparation of LaFe by chemical formula 13-z Si z (z=1.2,1.4,1.6) compound, concrete process is:

[0144] i) Press LaFe 13-z Si z (z=1.2, 1.4, 1.6) chemical formula weighing, mixing commercially available rare earth metal La, R, Fe, M and Si raw materials with a purity higher than 99.9%, wherein La is excessively 10% (atomic percentage) to compensate volatilization and burning damage;

[0145] ii) Put the raw materials prepared in step i) into the electric arc furnace, and evacuate to 2×10 -5 Torr and above, after cleaning 1 or 2 times with the usual high-purity argon cleaning method, use the usual method to repeatedly flip and melt for 3 times under the protection of high-purity argon at 1 atmosphere, until the melting temperature reaches melting;

[0146] iii) Cooling in a copper crucible to obtain the as-cast alloy; wrap the as-cast alloy with molybdenum foil, seal it in a vacuum quartz tube, ann...

Embodiment 2

[0153] Embodiment 2 prepares LaFe 11.5 Si 1.5 h α(α=0, 0.3, 0.6, 0.9, 1.3, 1.5, 1.8)

[0154] First, prepare LaFe by the technique of embodiment 1 11.5 Si 1.5 Master alloy, and then further prepare its interstitial hydride: Put the small fragments of the master alloy into the autoclave, add 5MPa high-purity H 2 Closed in an autoclave. Keep absorbing H at 150°C 2 The time is 2 hours, and the saturated hydride LaFe with α = 1.8 is obtained 11.5 Si 1.5 h 1.8 , and then dehydrogenated in a vacuum quartz tube for 40, 30, 20, 10 and 5 minutes at 250° C. to obtain interstitial hydrides of α=0.3, 0.6, 0.9, 1.3, and 1.5, respectively.

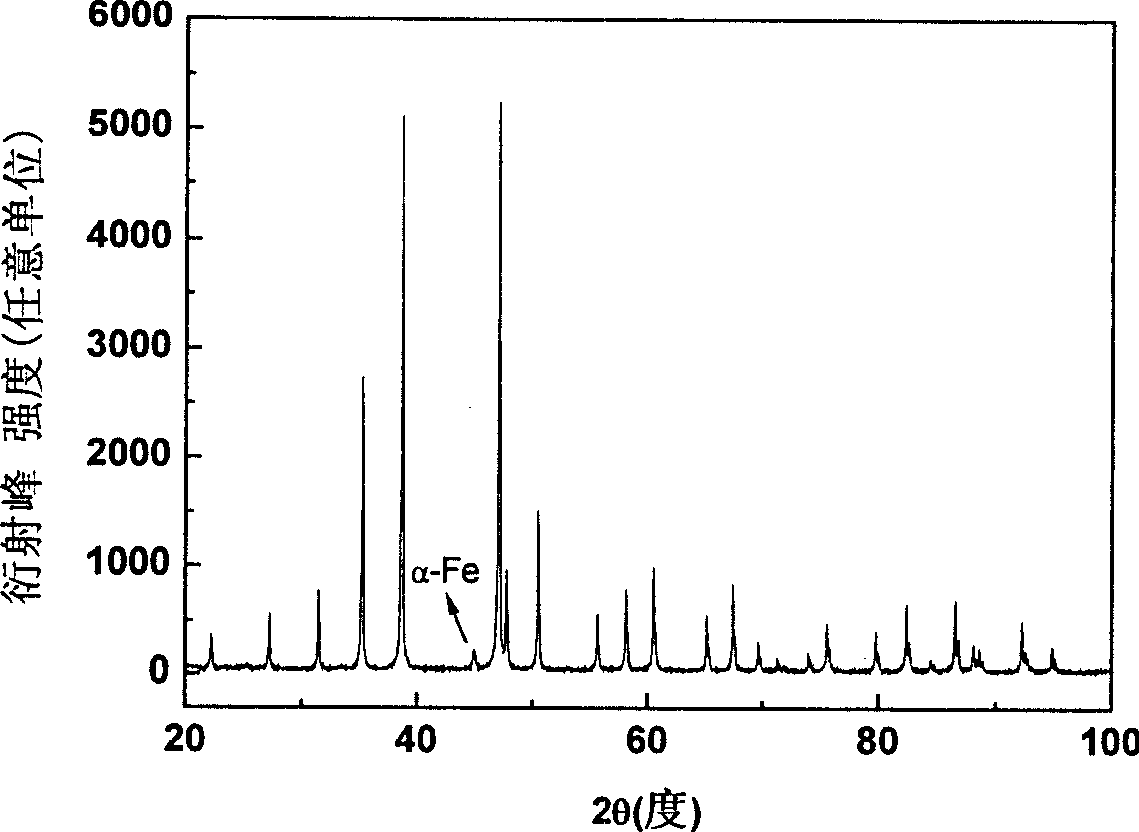

[0155] The example compound LaFe 11.5 Si 1.5 h α (α=0, 0.3, 1.3, 1.8) room temperature XRD lines such as Figure 5 shown. It can be seen from the figure: i) and LaFe 11.5 Si 1.5 h α (α=0) same as master alloy, interstitial hydride LaFe 11.5 Si 1.5 h α (α=0.3, 1.3, 1.8) all keep cubic NaZn 13 type structure, and the single-phase prop...

Embodiment 3

[0158] Example 3 Preparation of La(Fe 1-y mn y ) 11.7 Si 1.3 h α (y=0~0.03, α=0, 2.0)

[0159] Prepare La(Fe by embodiment 2 1-y mn y ) 11.7 Si 1.3 h α (y=0-0.03, α=0, 2.0) compounds, wherein Mn is added in excess of 10% (atomic percentage) to compensate for volatilization and burning loss during smelting.

[0160] Figure 9 shows that La(Fe 1-y mn y ) 11.7 Si 1.3 Room temperature XRD lines of the samples, as shown. It can be seen from the figure: i) and LaFe 11.7 Si 1.3 Like the master alloy, La(Fe 1-x mn x ) 11.7 Si 1.3 (y=0.01, 0.02, 0.03) are cubic NaZn 13 type structure, for y = 0.02 and 0.03, a small amount of α-Fe appeared; ii) the substitution of Fe by trace amount of Mn makes the lattice constant slightly increased, which is mainly due to the fact that the atomic radius of Mn is slightly higher than that of Fe due to the radius.

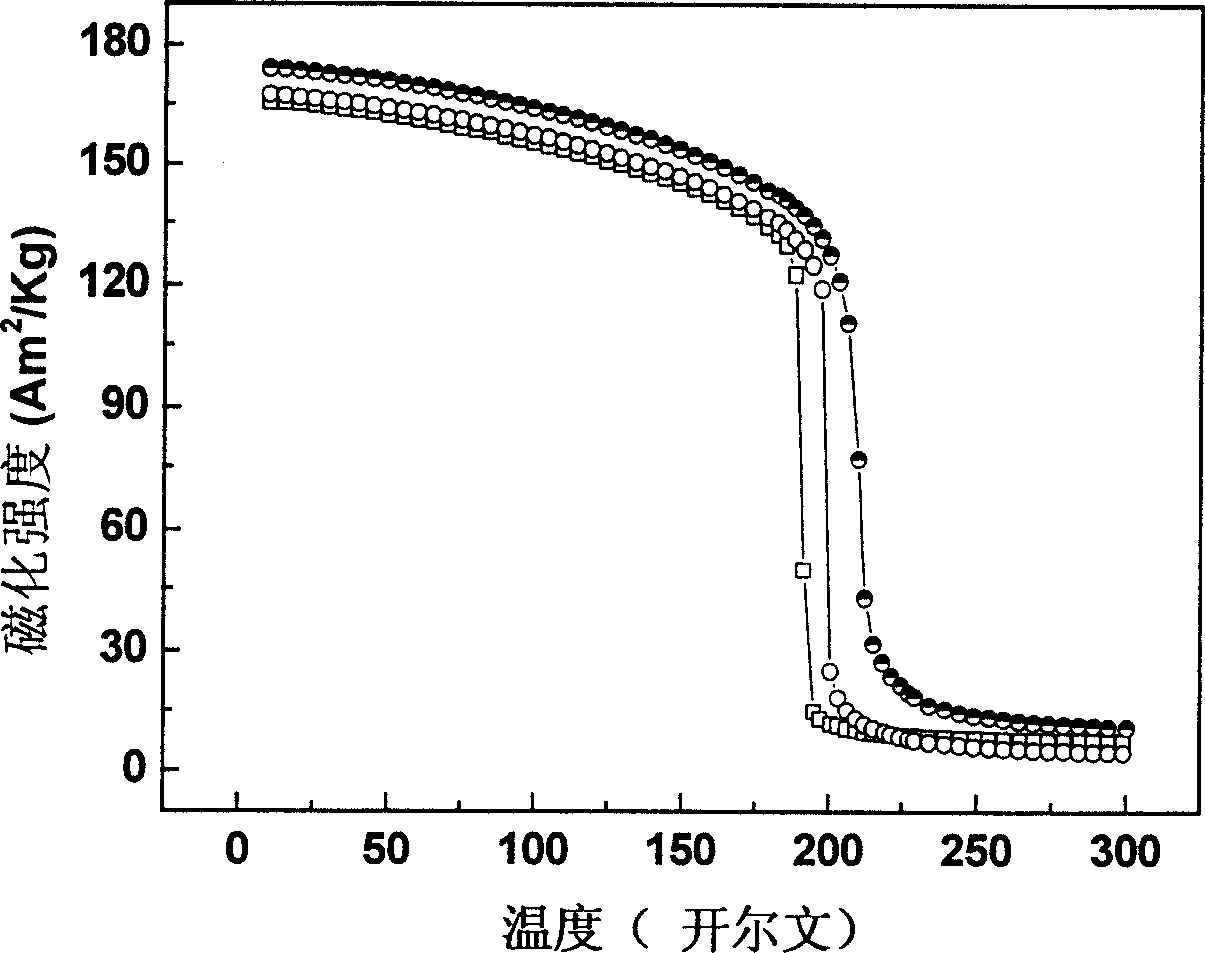

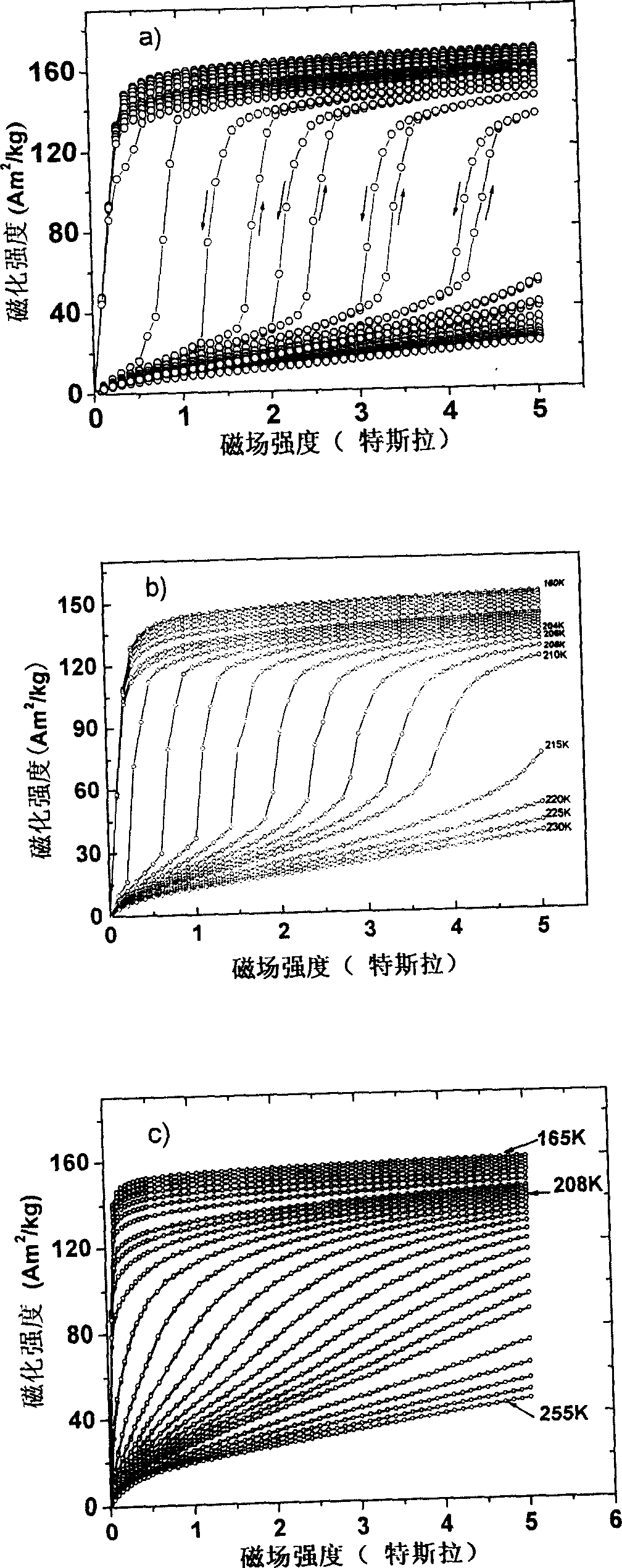

[0161] Figure 10 shows that under the condition of 100 Gauss, the compound La(Fe 1-y mn y ) 11.7 Si 1.3 h α (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com