Reclosable bag

a bag and reversible technology, applied in the field of containers, can solve the problems of forming an airtight seal, adding cost, and the device is more complicated than the conventional slider, and achieves the effect of convenient and convenient user closure, maintaining the freshness of perishable contents, and facilitating strong airtight seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

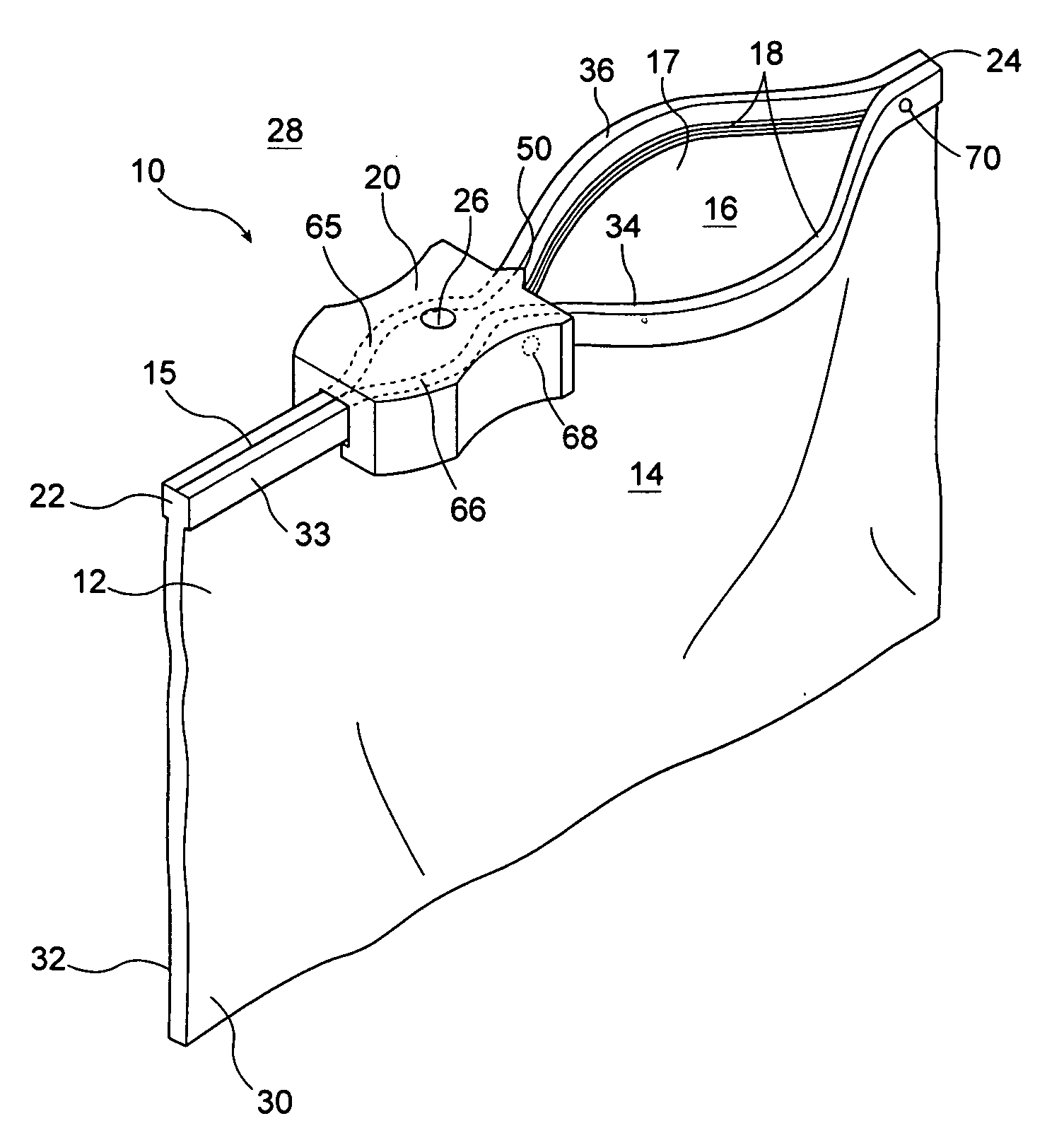

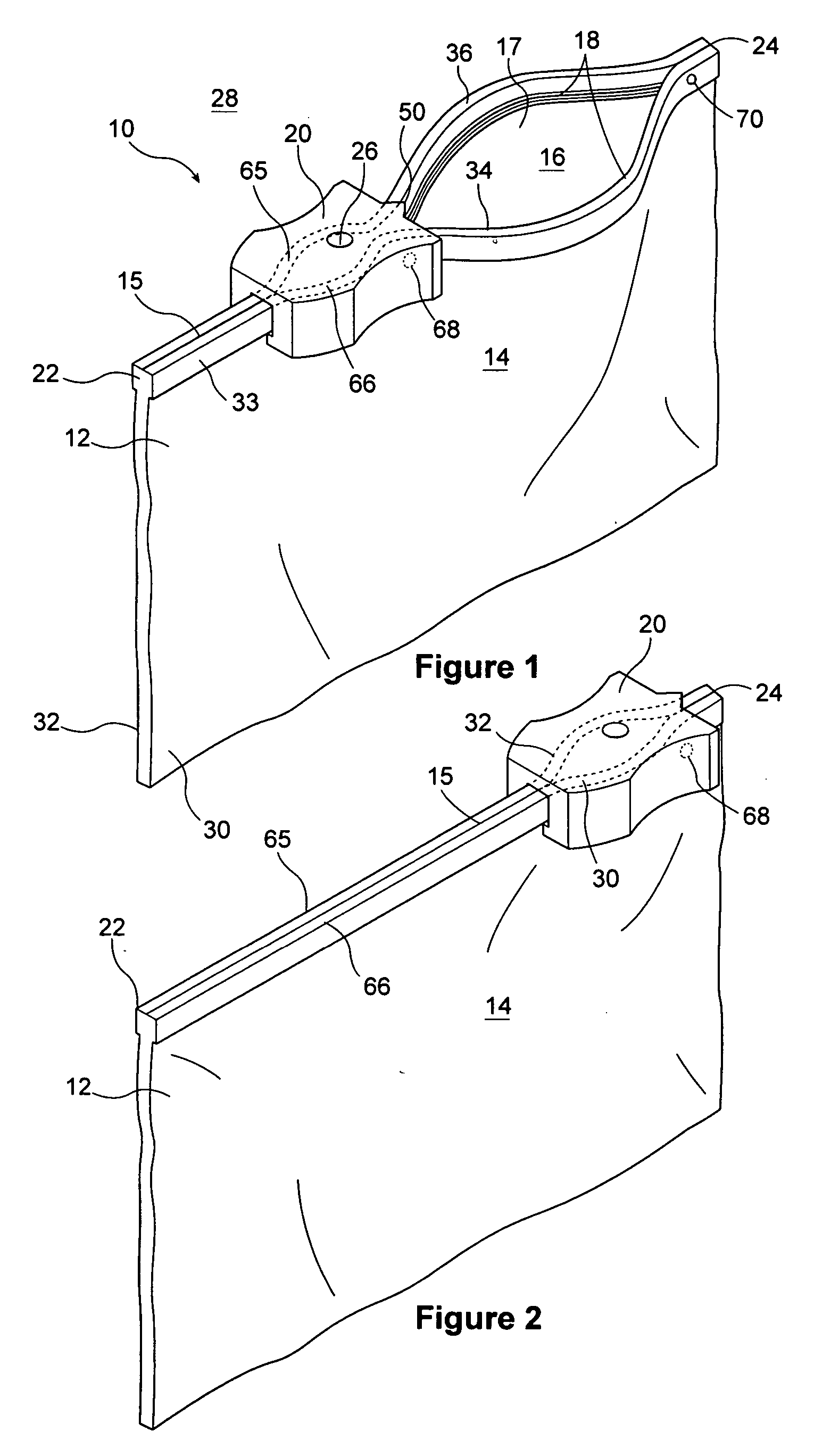

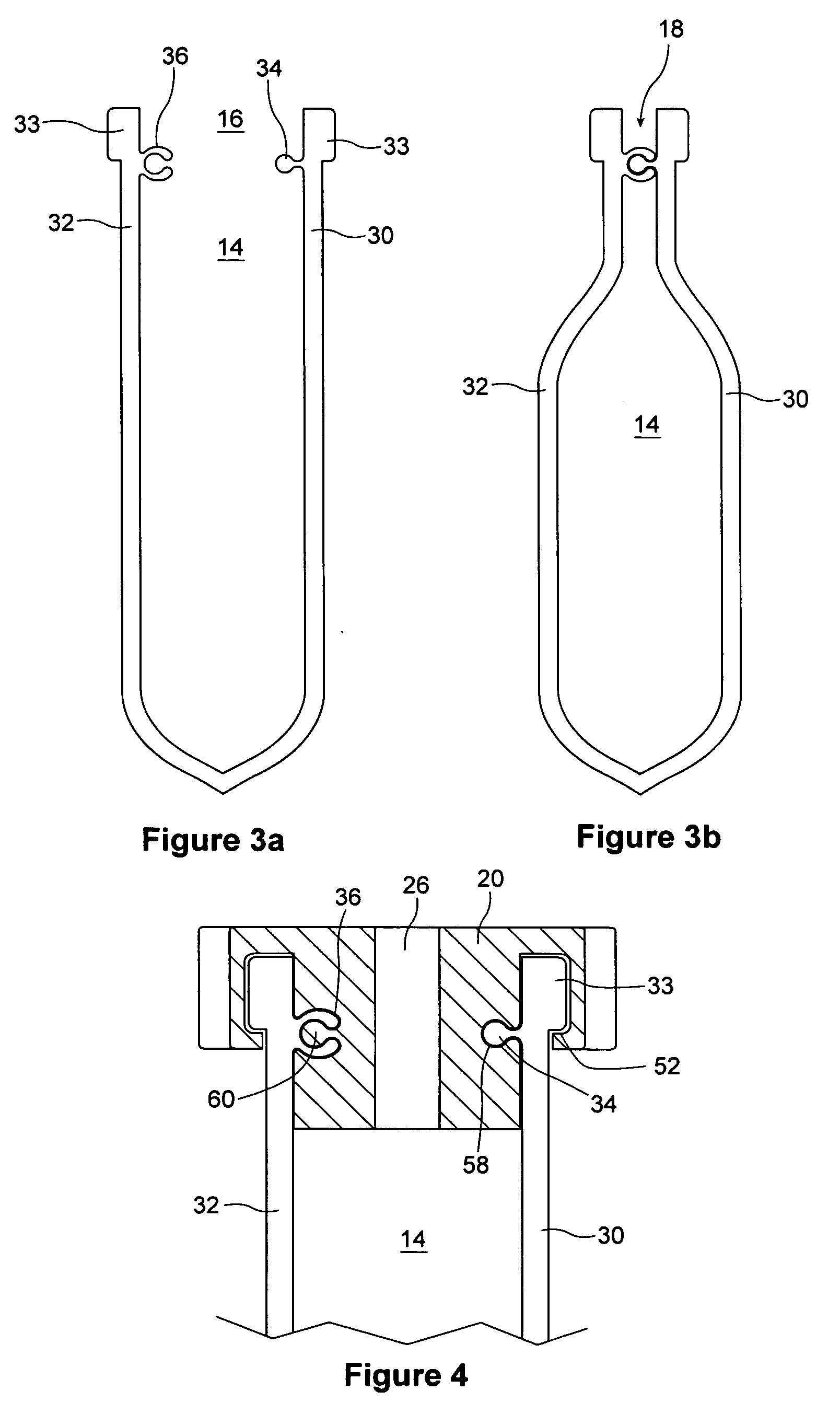

[0043] The closeable bag of the present invention is shown in FIG. 1, and is generally indicated with reference numeral 10. There is a bag portion 12 which defines a bag interior 14. The bag portion is generally sealed or closed along its edges except for a bag opening 16, which defines an unsealed section that can be selectively opened or closed. In FIG. 1 bag opening 16 is the top unsealed side of the bag between end 22 and end 24.

[0044] The closeable bag includes a means for selectively opening and closing the bag opening. The means for opening and closing generally comprises two elements—opposed interlocking features 18 along the bag opening 16, and a slider 20. The slider 20 is positioned in the bag opening 16, between the opposed interlocking features 18, and is generally movable along at least a portion of their length. The slider 20 is further configured so that as it moves, it causes the portion of the opposed interlocking features 18 that it passes to engage or disengage....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com