A method for denitrification in sintering process using various flue gases

A sintering process and flue gas technology, which is applied in the fields of steelmaking and ironmaking tail gas treatment, energy saving and emission reduction, can solve the problems of not meeting sintering production, reducing the temperature of circulating flue gas, and low flue gas temperature, and achieve the improvement of denitrification efficiency and improvement Quality, reduce the effect of coke powder consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

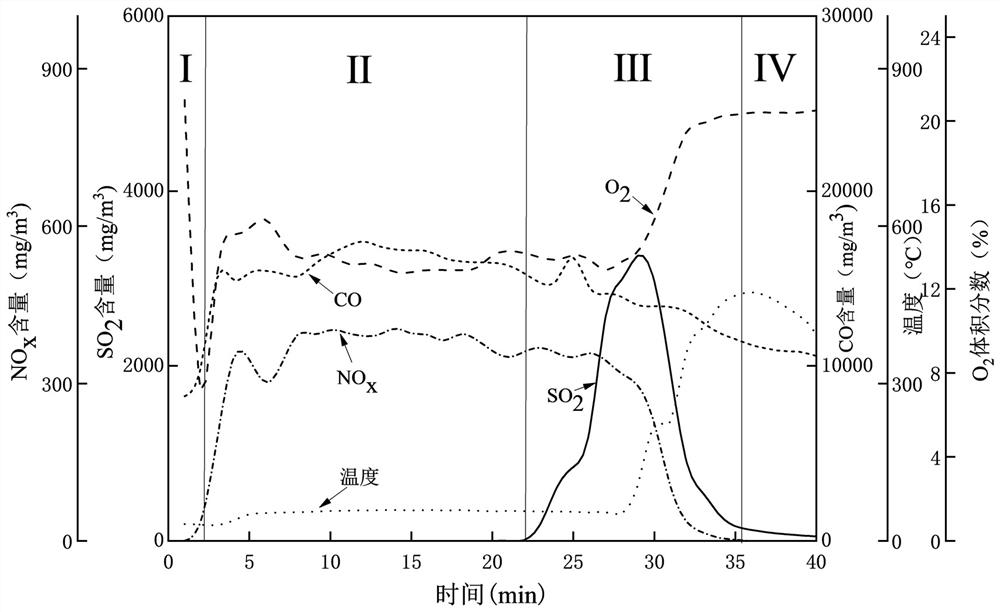

[0027] The method for denitrification by mixing various types of flue gas proposed by the present invention mainly uses the flue gas from the furnace after desulfurization in various processes such as blast furnaces, refining furnaces, hot blast furnaces, heating furnaces, etc. On the premise of quality, the NOx generated during the sintering process is removed. Its removal effect is significantly more stable, no additional heating is required, no new pollutants are generated, and the cost is lower than that of the SCR method and the SNCR method. the cost of.

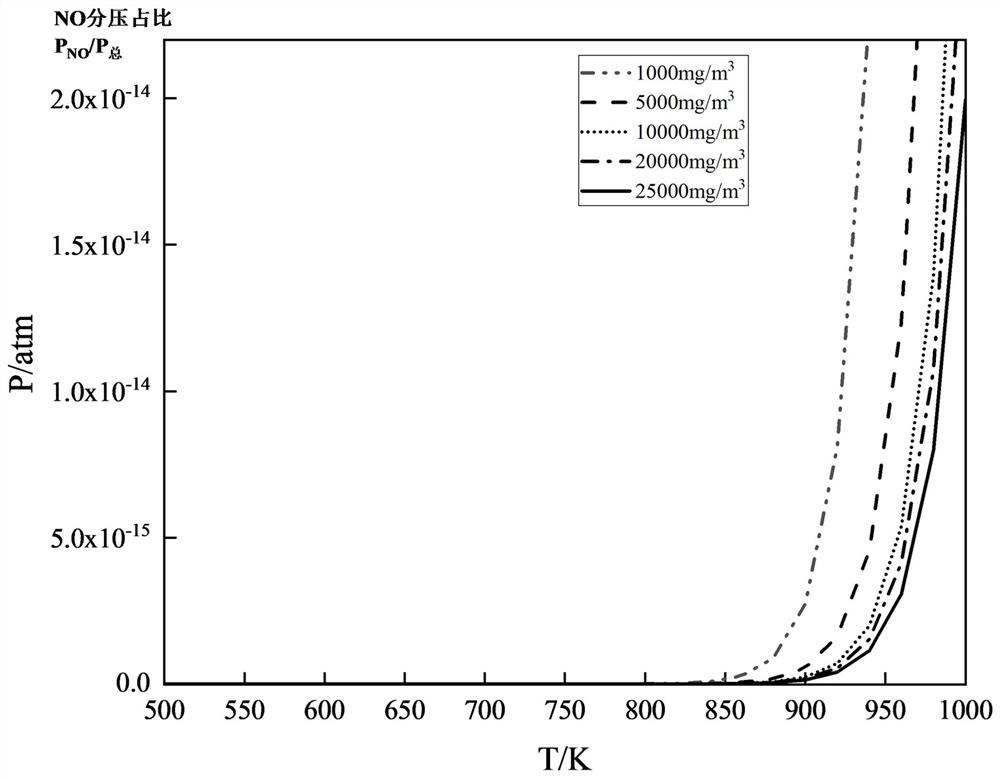

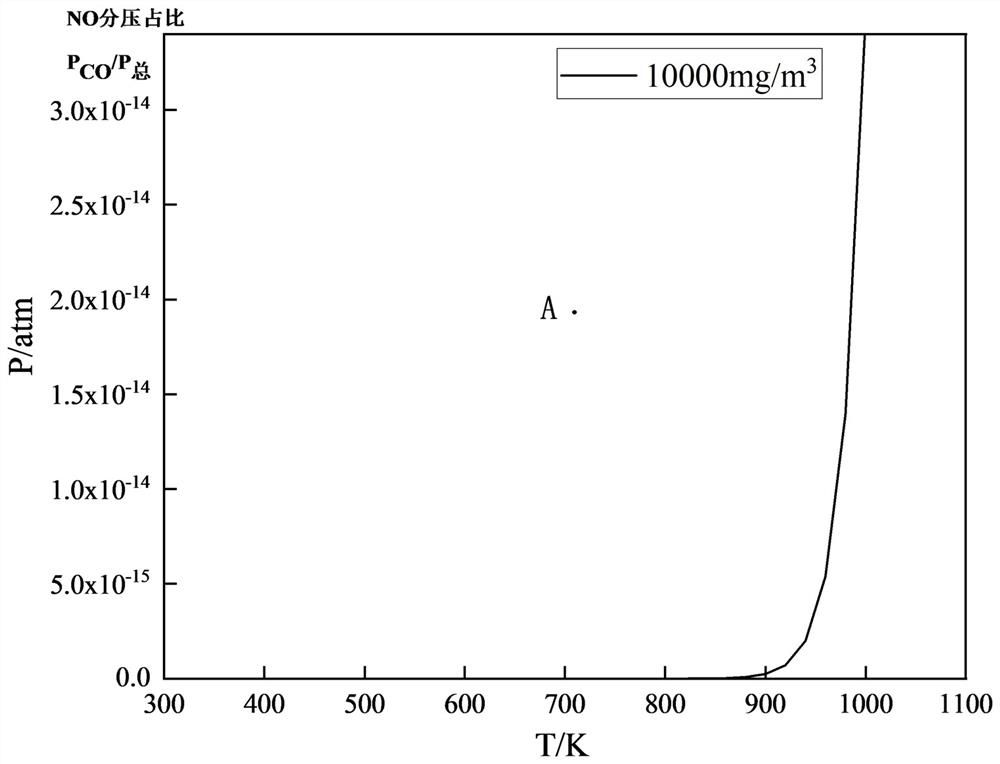

[0028] For the reaction (1) the reaction standard equilibrium constant K θ It is only a function of temperature, as long as the reaction temperature is constant, then K θ must. Pressure Equilibrium Constant K P It is only related to the reaction temperature and the nature of the reaction. This reaction K is obtained by summing 2+2-2-1=1 according to the stoichiometric number P with K θ The relationship is shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com