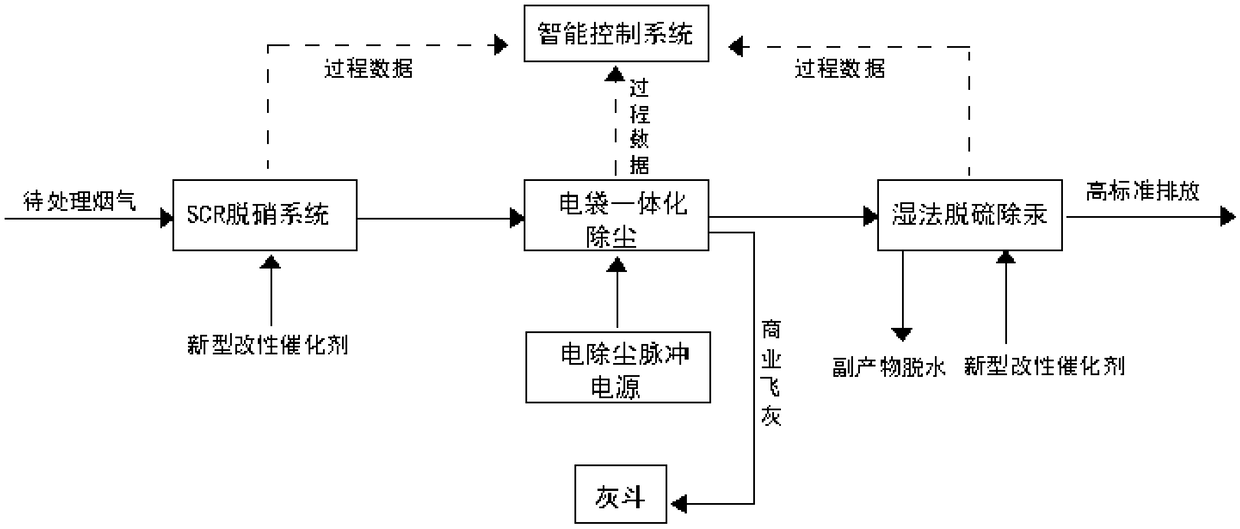

Intelligent cooperative control method of multiple contaminants in coal-fired industrial source flue gas

A technology for collaborative control and pollutants, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of increasing system complexity and failure rate, low processing efficiency, and inability to coordinate control, and reduce system failure rate. , Improve removal efficiency and reduce operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

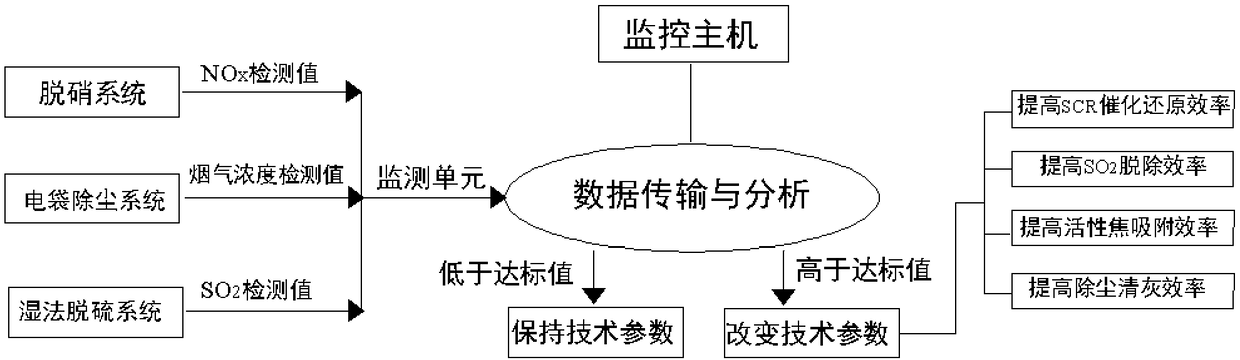

[0029] Before the flue gas from a thermal power plant enters the system, SO 2 The concentration is 1200mg / m 3 ,NO x The concentration is 600mg / m 3 , soot concentration is 500mg / m 3 , the concentration of arsenic and its compounds is 0.5mg / m 3 , the concentration of mercury and its compounds is 0.06mg / m 3 , the chloride concentration is 6mg / m 3 ,, the flue gas volume is 25000m 3 / h.

[0030] After adopting the process of the present invention, the SO2 detected by the online monitoring system in real time 2 Emission concentration is 90mg / m 3 ,NO x Concentration is 85mg / m 3 , soot concentration is 25mg / m 3 , the concentration of arsenic and its compounds is 0.02mg / m 3 , the concentration of mercury and its compounds is 0.003 mg / m 3 , the chloride concentration is 0.2mg / m 3 . Among them, SO 2 Concentration (90mg / m 3 ) is greater than the allowable emission concentration of the system (the desulfurization rate is 95%, that is, 60mg / m 3 ), and the other emission co...

Embodiment 2

[0032] Before the flue gas from a coal-fired plant enters the system, SO 2 The concentration is 1100mg / m 3 ,NO x The concentration is 800mg / m 3 , soot concentration is 600mg / m 3 , the concentration of arsenic and its compounds is 0.35mg / m 3 , the concentration of mercury and its compounds is 0.07mg / m 3 , the chloride concentration is 10mg / m 3 , the flue gas volume is 100000m 3 / h.

[0033] After adopting the technique of the present invention, the SO that the on-line monitoring system monitors in real time 2 The emission concentration is 48mg / m 3 , NO x The concentration is 45mg / m 3 , soot concentration is 60mg / m 3 , the concentration of arsenic and its compounds is 0.01mg / m 3 , the concentration of mercury and its compounds is 0.001mg / m 3 , the chloride concentration is 0.5mg / m 3 . Among them, the smoke concentration (60mg / m 3 ) is greater than the allowable emission concentration of the system (the dust removal rate is 95%, that is, 30mg / m 3 ), and the other...

Embodiment 3

[0035] Flue gas from a clean coal-fired plant, before entering the system, SO 2 The concentration is 800mg / m 3 ,NO x The concentration is 850mg / m 3 , soot concentration is 350mg / m 3 , the concentration of arsenic and its compounds is 0.23mg / m 3 , the concentration of mercury and its compounds is 0.05mg / m 3 , the chloride concentration is 2mg / m 3 , the flue gas volume is 80000m 3 / h.

[0036] After adopting the process of the present invention, the emitted SO 2 The concentration is 33mg / m 3 ,NO x The concentration is 140mg / m 3 , soot concentration is 15mg / m 3 , the concentration of arsenic and its compounds is 0.005mg / m 3 , the concentration of mercury and its compounds is 0.001mg / m 3 , the chloride concentration is 0.1mg / m 3 . Among them, NO x Concentration (140mg / m 3 ) greater than the allowable emission concentration of the system (dust removal rate 85%, ie 127 mg / m 3 ), and the other emission concentrations are all lower than the allowable emission concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com