Ozone electrolysis chamber electrolysis structure

An electrolysis chamber and ozone technology, applied in the electrolysis process, electrolysis components, oxidized water/sewage treatment and other directions, can solve the problems of difficult processing and production, prone to reverse reactions in the electrolysis chamber, and high procurement costs, to prevent the electrode from burning out, The effect of promoting electrolysis efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

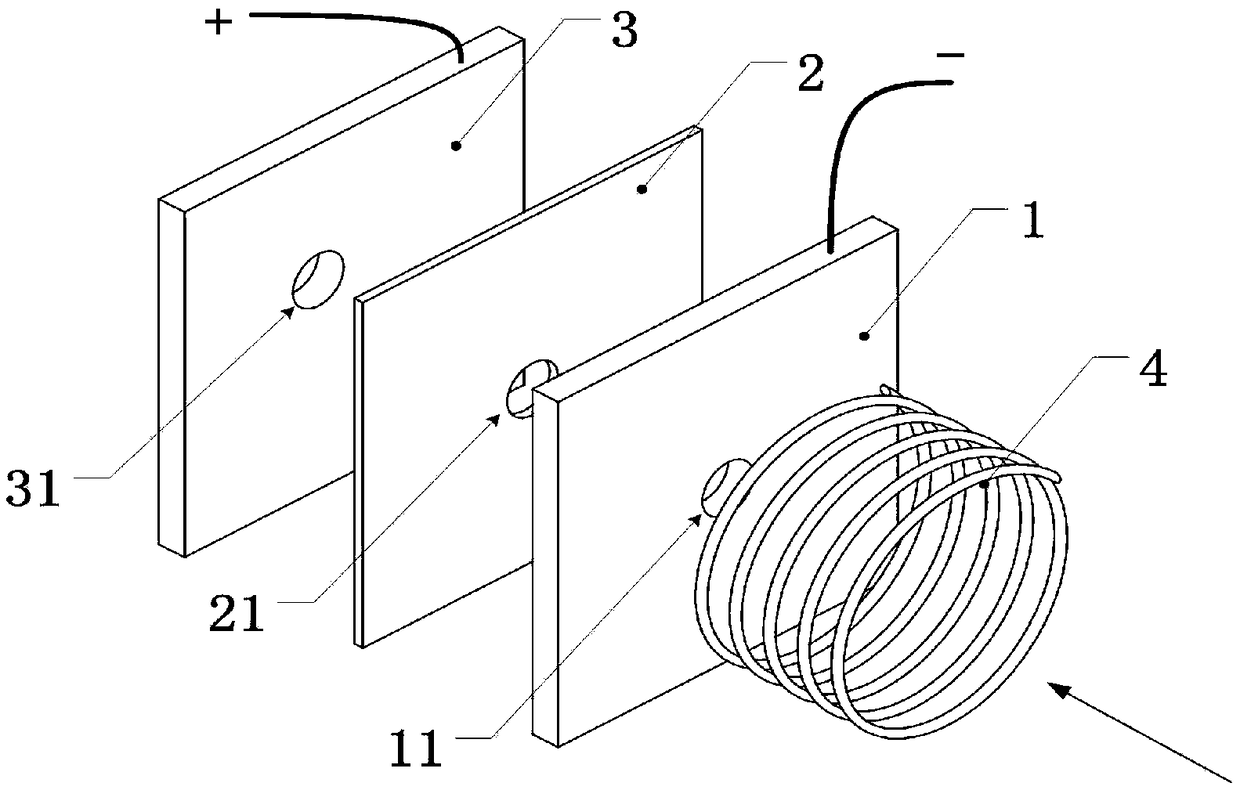

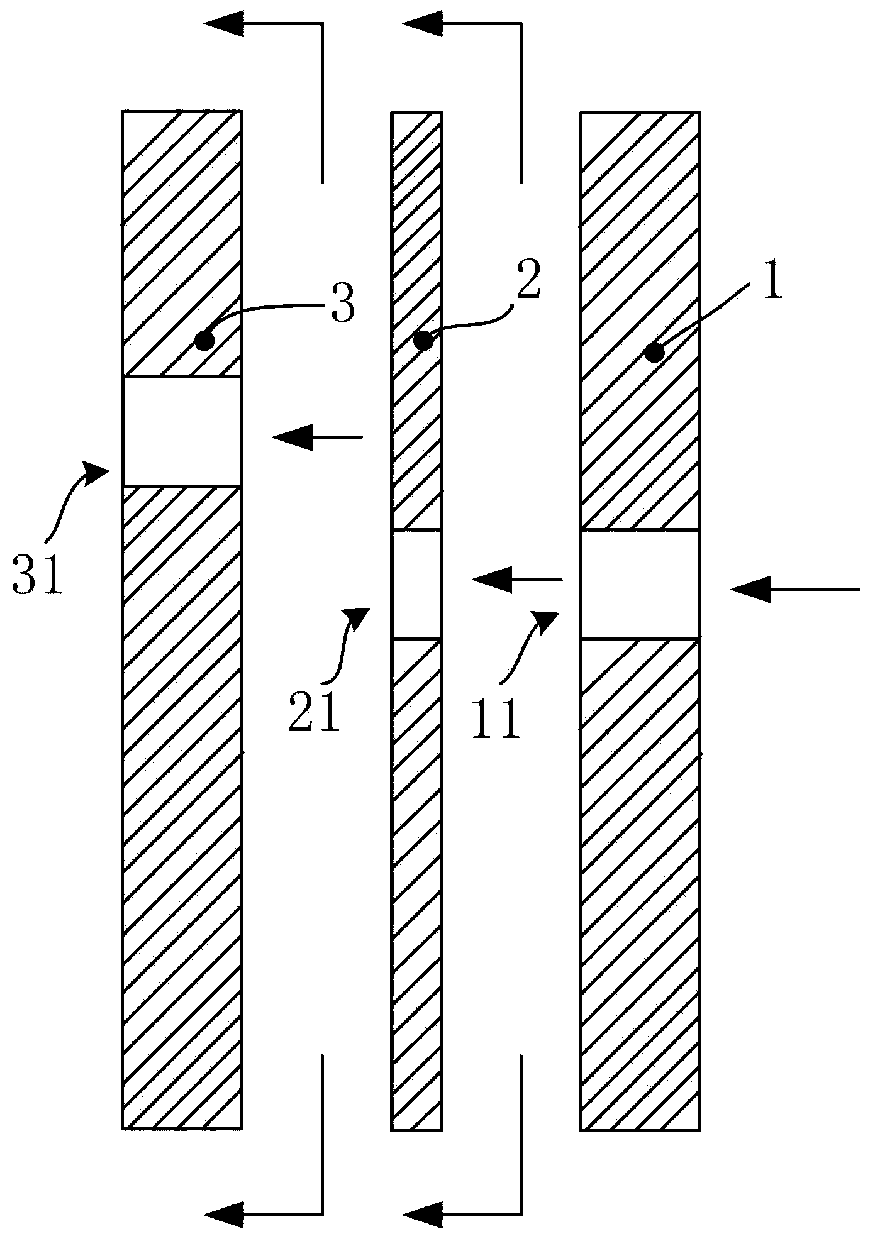

[0042] See figure 1 and figure 2 , the electrolytic structure of the ozone electrolysis chamber of the present embodiment mainly includes a cathode sheet 1, a diaphragm 2, an anode sheet 3 and a spring 4, and along the flow direction from the water inlet end to the water outlet end, the arrangement of the above four structures is spring 4, The cathode piece 1, the diaphragm 2 and the anode piece 3, and one end of the spring 4 abuts against the side of the cathode piece 1 facing the water inlet end.

[0043] Preferably, the cathode sheet 1 of this embodiment is made of stainless steel, the diaphragm 2 is a proton exchange membrane, and the anode sheet 3 is a diamond sheet.

[0044] The profile of the cathode sheet 1 of this embodiment is rectangular, and its end face is provided with a circular first through hole 11, and the other side of the cathode sheet 1 is parallel to the rectangular diaphragm 2, and the diaphragm 2 surface is provided with the first through hole 11. Th...

Embodiment 2

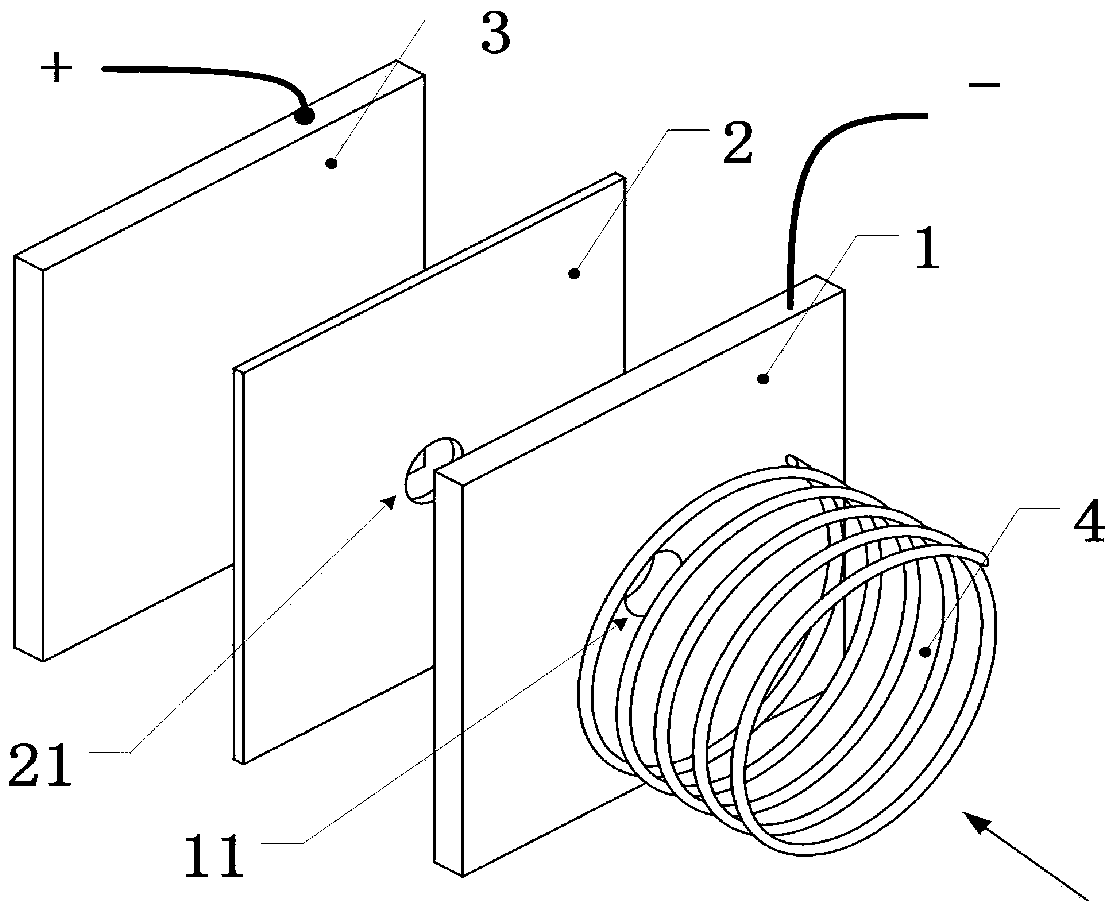

[0053] See image 3 and Figure 4 , the electrolytic structure of the ozone electrolysis chamber of the present embodiment mainly includes a cathode sheet 1, a diaphragm 2, an anode sheet 3 and a spring 4, and along the flow direction from the water inlet end to the water outlet end, the arrangement of the above four structures is spring 4, The cathode piece 1, the diaphragm 2 and the anode piece 3, and one end of the spring 4 abuts against the side of the cathode piece 1 facing the water inlet end.

[0054] Preferably, the cathode sheet 1 of this embodiment is made of stainless steel, the diaphragm 2 is a proton exchange membrane, and the anode sheet 3 is a diamond sheet.

[0055] The profile of the cathode sheet 1 of the present embodiment is rectangular, and its end face is provided with a circular first through hole 11, and the other side of the cathode sheet 1 is parallel to the rectangular diaphragm 2, and the diaphragm 2 surface is provided with the second through hole...

Embodiment 3

[0062] See Figure 5 The difference technical feature of this embodiment relative to Embodiment 1 is that the first through hole 11 provided on the surface of the cathode sheet 1 and the second through hole 21 provided on the surface of the diaphragm 2 are all triangular, and the first through hole 11 and the second through hole 21 provided on the surface of the diaphragm 2 The second through holes 21 have the same external dimensions and overlap axially, the number of the first through holes 11 and the second through holes 21 is three, and the third through holes 31 provided on the surface of the anode sheet 3 are also three triangles through holes, but the third through hole 31 is staggered from the first through hole 11 and the second through hole 21 respectively and there is no partial overlap in the axial direction. In addition, the outer end surface of the anode sheet 3 is against one end of the spring 4, and the other end of the spring 4 One end is against the inner wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com